Wind-driven generator

A technology for wind turbines and motor shafts, which is applied to wind turbines, wind turbine combinations, wind energy power generation, etc., can solve the problems of easy breakage of solid shafts, thick motor shafts, and high cost, and achieve overall stability and balance. The effect of reducing weight and cost, extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

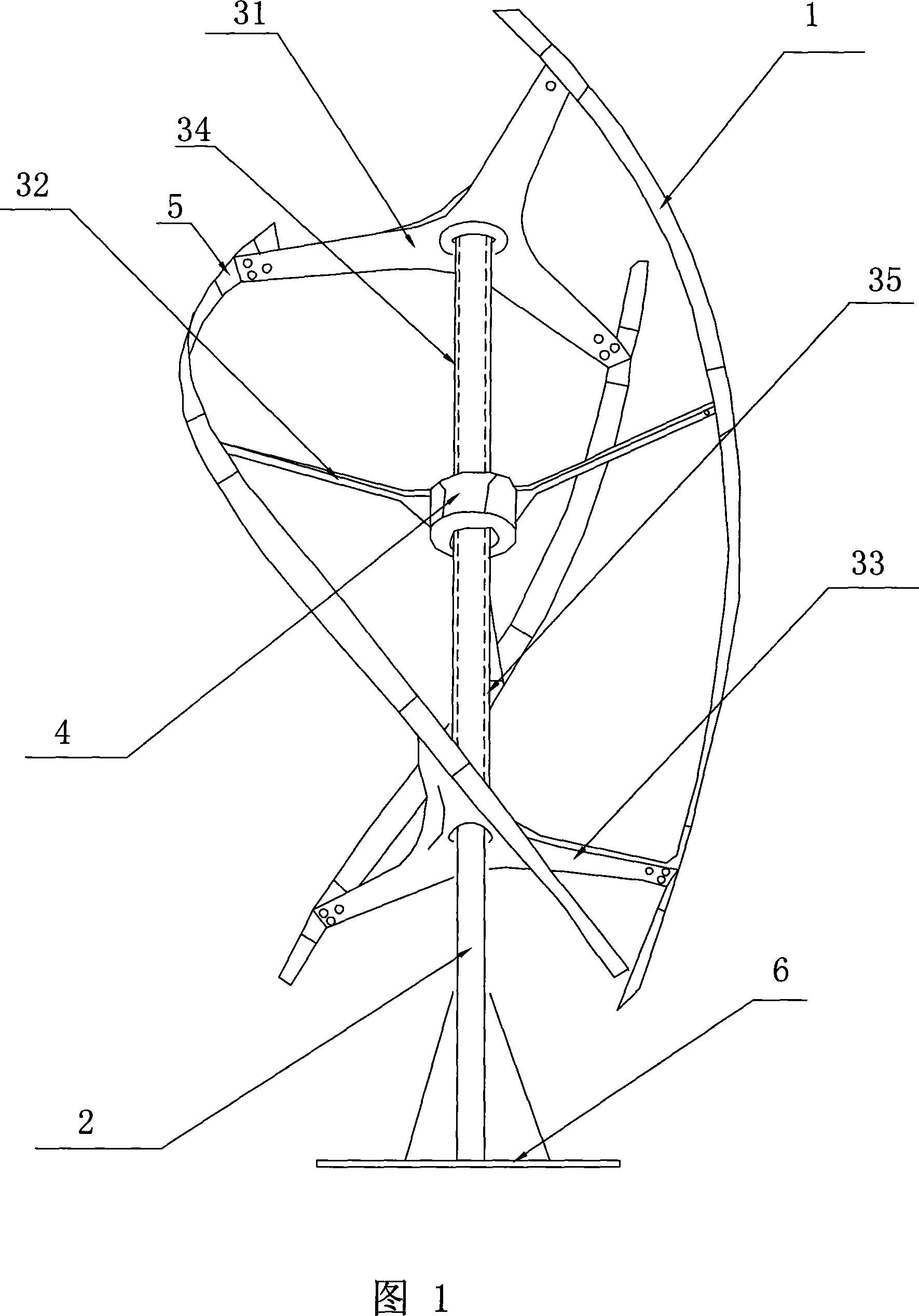

[0065] As shown in Figure 1, the present invention comprises three independent blades 1, a longitudinal central axis 2, an upper support 31, a middle support 32 and a lower part which are horizontally arranged on the upper, middle and lower parts of the longitudinal central axis 2 and which can rotate around the longitudinal central axis 2 Support 33, motor 4 can be fixedly connected with any support.

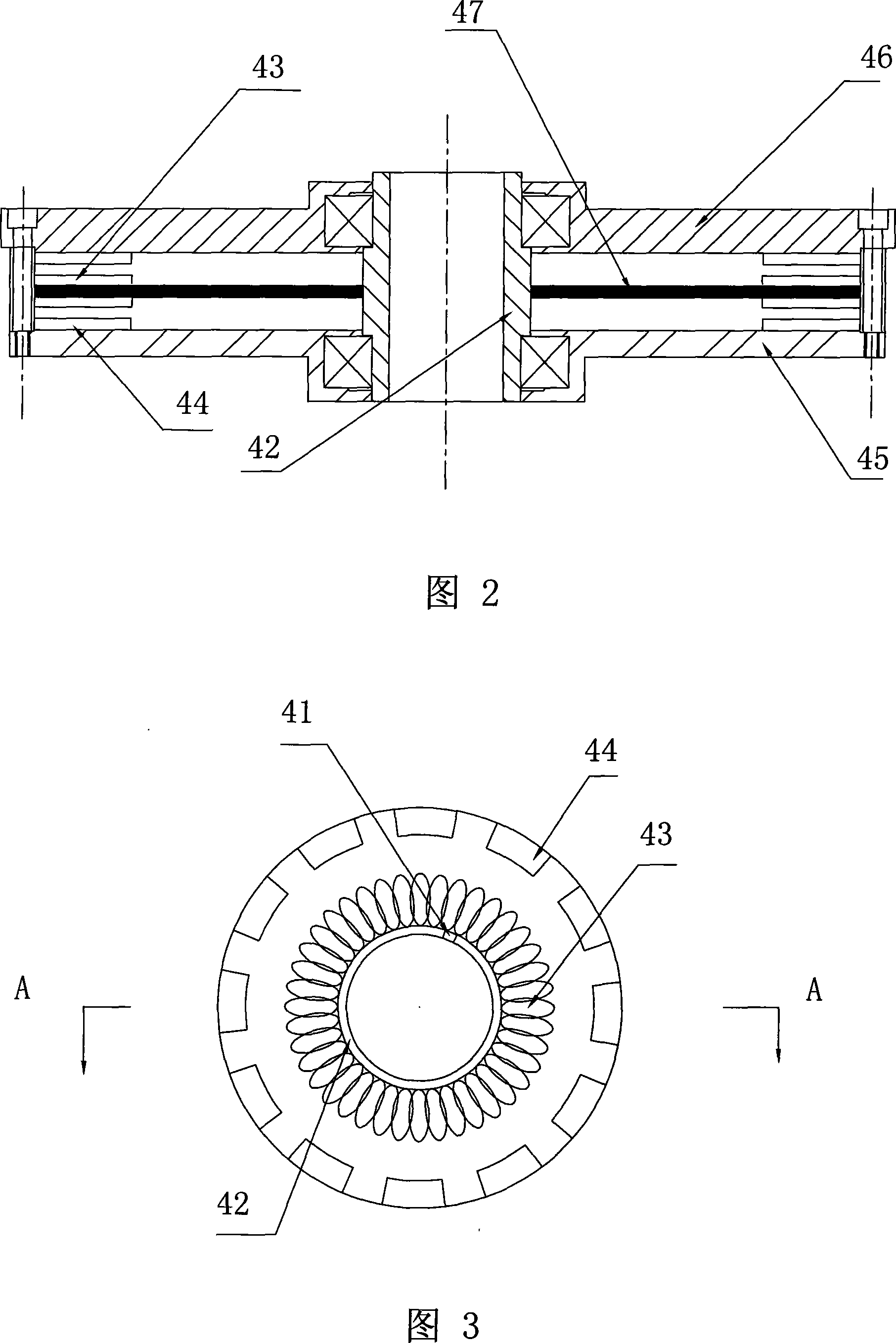

[0066] As shown in FIG. 1 , the motor 4 is set at the center of the middle bracket 32 . As shown in FIG. 7 , the longitudinal center shaft 2 passes through the hollow shaft 42 and has an interference fit with it. The longitudinal central axis 2 does not rotate, and the motor 4 and each support rotate around the longitudinal central axis 2. Therefore, compared with the prior art, for a motor with the same power, the hollow shaft 42 not only reduces the cost compared to the solid shaft, but also greatly reduces the weight of the motor itself.

[0067] The structure of the mot...

Embodiment 2

[0076] The motor 4 in the first embodiment can also adopt the following structure:

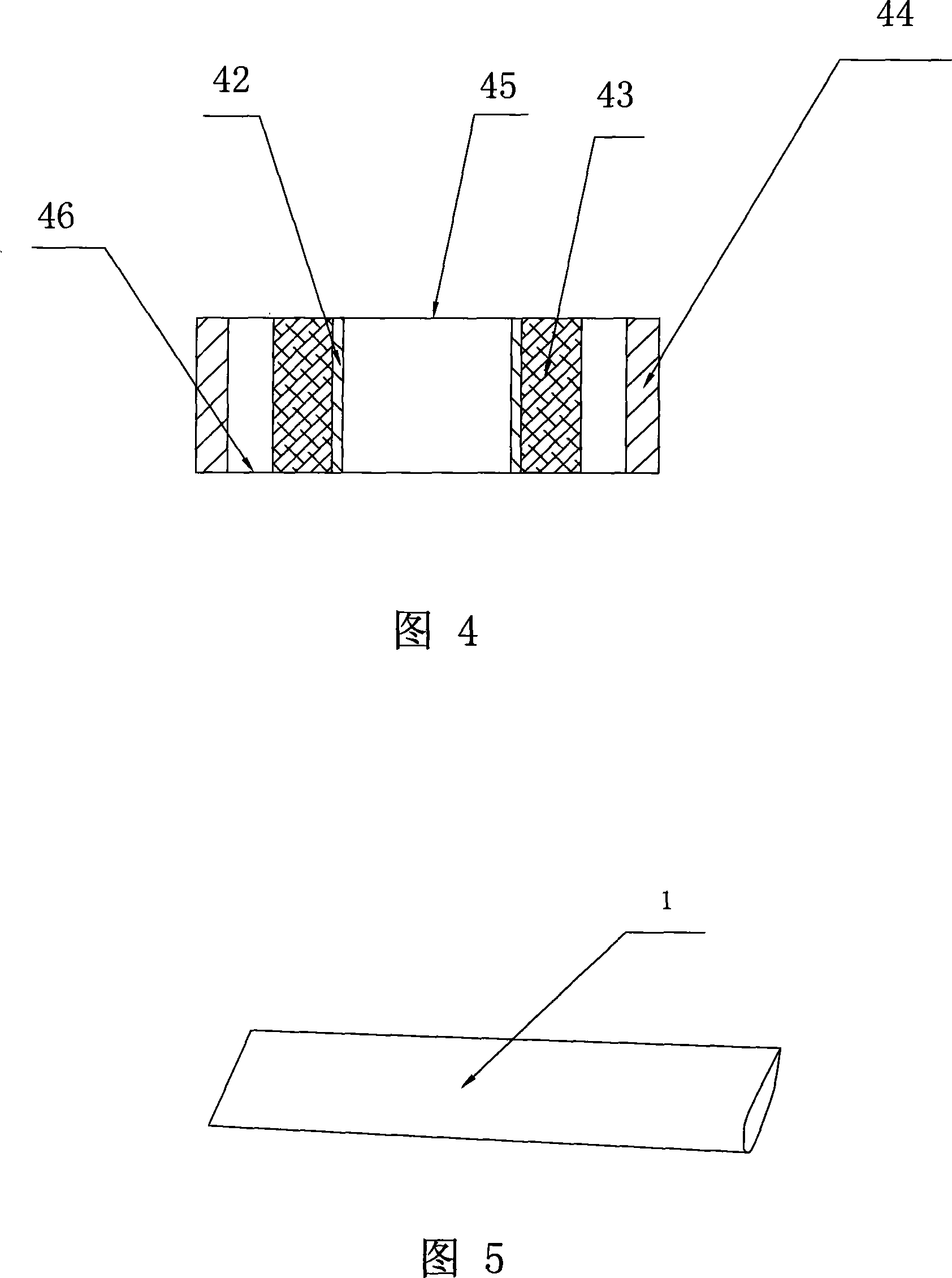

[0077] As shown in FIGS. 3-4 , the motor 4 includes a hollow shaft 42 , a motor upper cover 45 , and a lower cover 46 . The upper cover 45 and the lower cover 46 can rotate around the hollow shaft 42 . The stator and the rotor are disposed between the upper cover 45 and the lower cover 46 . The coil 43 is wound on the outside of the hollow shaft 42 to form a stator; the rotor is a magnetic steel 44 arranged on the outer ring, which can rotate around the hollow shaft 42 with the upper cover 45 and the lower cover 46 . Both the coil 43 and the magnetic steel 44 are arranged coaxially with the hollow shaft 42, and the hollow shaft 42 is provided with a wire groove 41 for extracting electric energy.

[0078] Compared with the prior art, for a motor with the same power, the hollow shaft 42 not only reduces the cost compared to the solid shaft, but also greatly reduces the weight of the motor itse...

Embodiment 3

[0080] As shown in Fig. 1, the blade 1 is made of flexible material, such as high molecular hydrocarbon polymer polylefins, and can be spiral or airfoil. The upper bracket 31, the middle bracket 32 and the lower bracket 33 can all rotate around the longitudinal central axis 2, and the end points of the three brackets are respectively connected with the upper, middle and lower parts of the blade 1, so that the installed three blades 1 can rotate around the longitudinal central axis. 2 Evenly set, and from top to bottom in a spiral or S-shape. Of course, the installed blade 1 can also be straight from top to bottom. Since the blade 1 is a flexible material, it cannot be welded together with the upper bracket 31 , the middle bracket 32 and the lower bracket 33 , and must be fastened through the connecting piece 5 .

[0081] The blade 1 is made of flexible material, so there is no possibility of the blade being broken by strong wind. Therefore, there is no need to take overs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com