Intelligent sleeve type high temperature high voltage solenoid valve

A high-temperature, high-pressure, sleeve-type technology, applied in the field of solenoid valves, achieves remote control, eliminates the influence of magnetic permeability, and has the effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

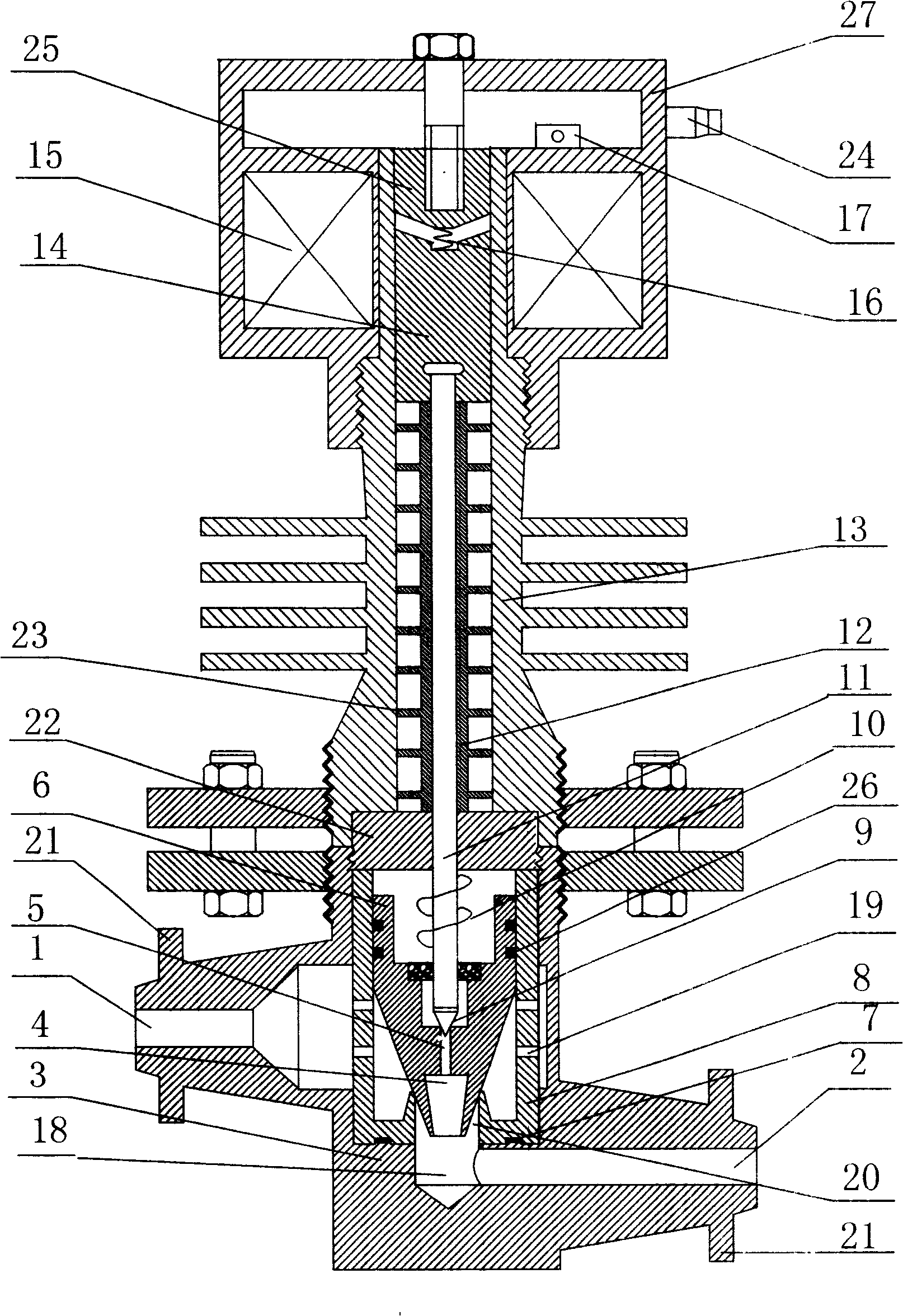

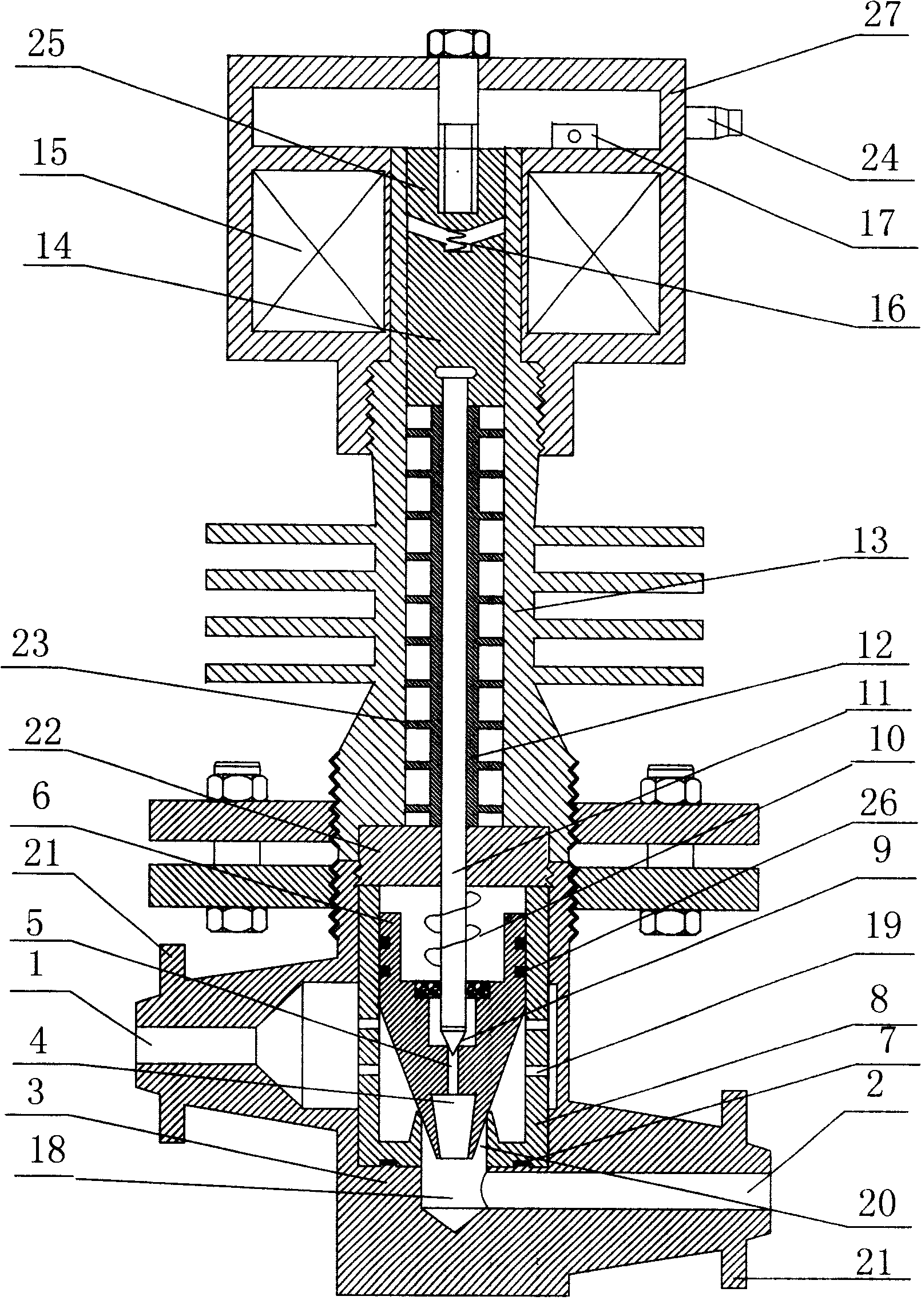

[0024] Such as figure 1 As shown, the intelligent sleeve type high temperature and high pressure solenoid valve includes a shielding sleeve 13, a valve body 3, an electromagnetic coil 15, a valve seat sleeve 8, a valve disc 6, a valve stem 11, a signal feedback device 17, and a threaded conductor 22. The outside of the shielding sleeve 13 has cooling fins, and the lower end of the shielding sleeve 13 is connected to the upper end of the valve body 3 with a flange.

[0025] A medium inlet port 1 is provided at the lower part of the valve body 3, a medium outlet port 2 is provided at the lower part opposite to the medium inlet port 1, and a central medium channel 18 is provided between the medium inlet port 1 and the medium outlet port 2. The end 1 and the medium outlet end 2 are also provided with process flanges 21 for inspection and testing. Valve body 3 is equipped with valve seat sleeve 8, the bottom end of valve seat sleeve 8 is inlaid on valve body 3, and the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com