Technology for reducing obstruction in magnesium oxide method desulfurizing device

A desulfurization device, magnesium oxide technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems affecting the normal operation of desulfurization devices, fast settling speed, blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

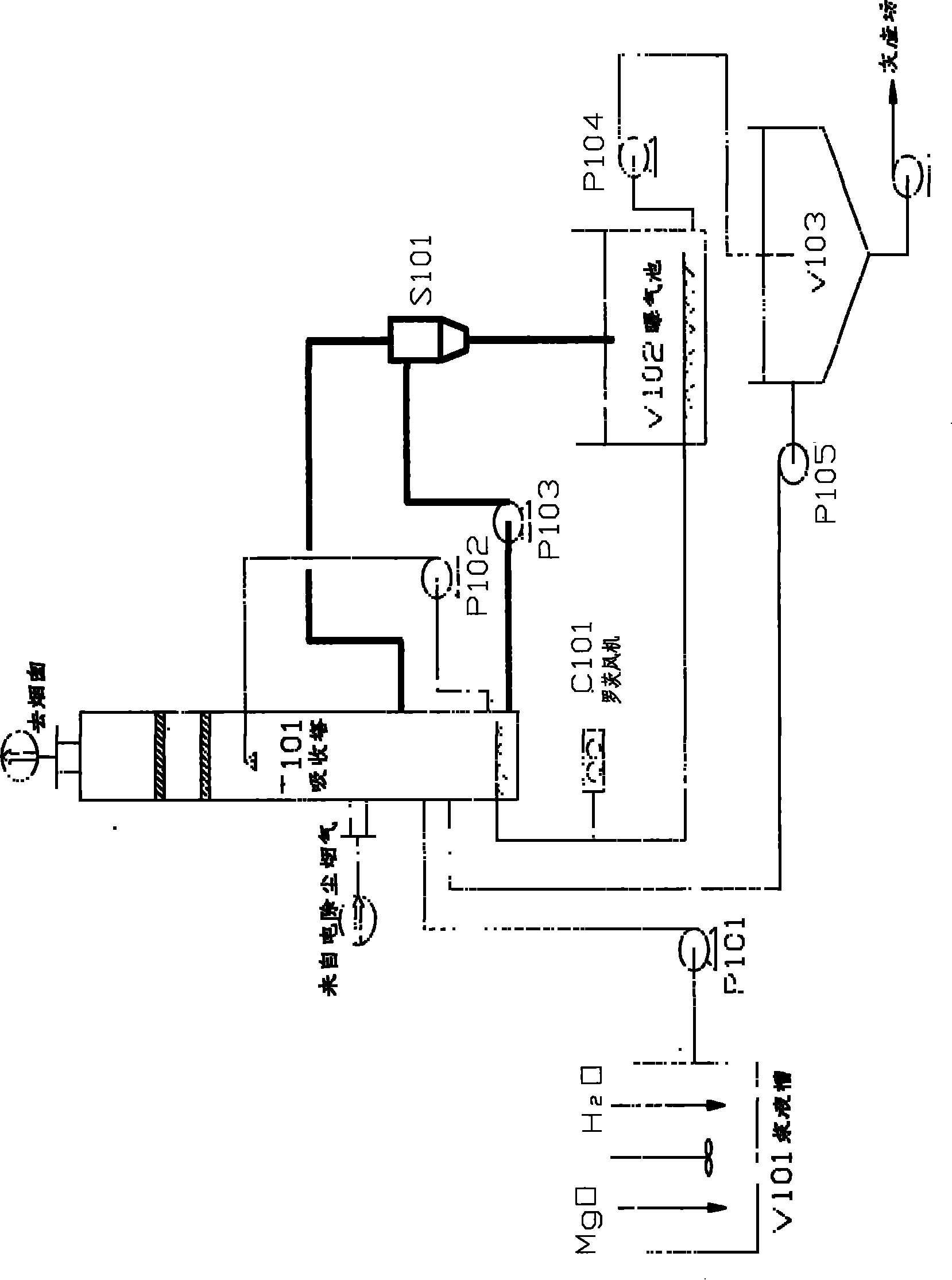

[0034] As shown in Figure 1, MgO is added to the absorption tower (T101) directly after adding water and ripening to make MgO slurry. Since the air is introduced into the tower for aeration and oxidation, sand particles are not easy to deposit at the bottom of the tower. In addition, a mud pump (P103 ) to send the absorption liquid containing sand particles to the hydrocyclone (S101) to remove the sand particles, the overflow liquid returns to the absorption tower, the bottom liquid flows into the aeration tank (V102), and is further aerated and oxidized with air, and the magnesium sulfite magnesium oxide is Magnesium sulfate is then sent to the clarification tank (V103) by the mud pump (P104) for clarification, the clarified liquid is sent back to the absorption tower by the absorption liquid pump (P105), and the sand slurry at the bottom of the tower is sent to the ash yard by the mud pump (P106).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com