Long fibre enhanced polypropylene/nylon composite material and preparation method thereof

A nylon composite material and polypropylene technology, applied in the field of polymer materials, can solve the problems of limited application, inability to obtain mechanical properties of long-fiber reinforced polypropylene/nylon composite materials, easy delamination, etc., and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

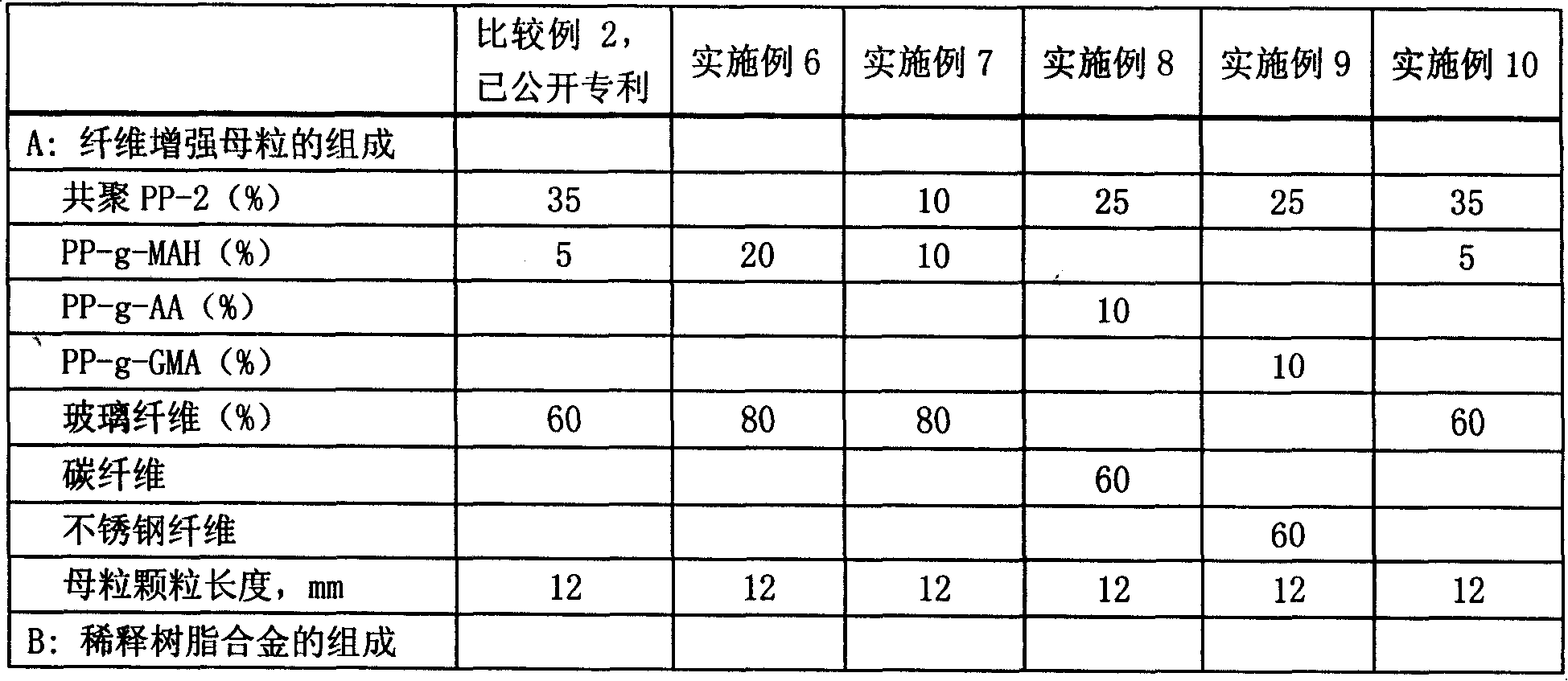

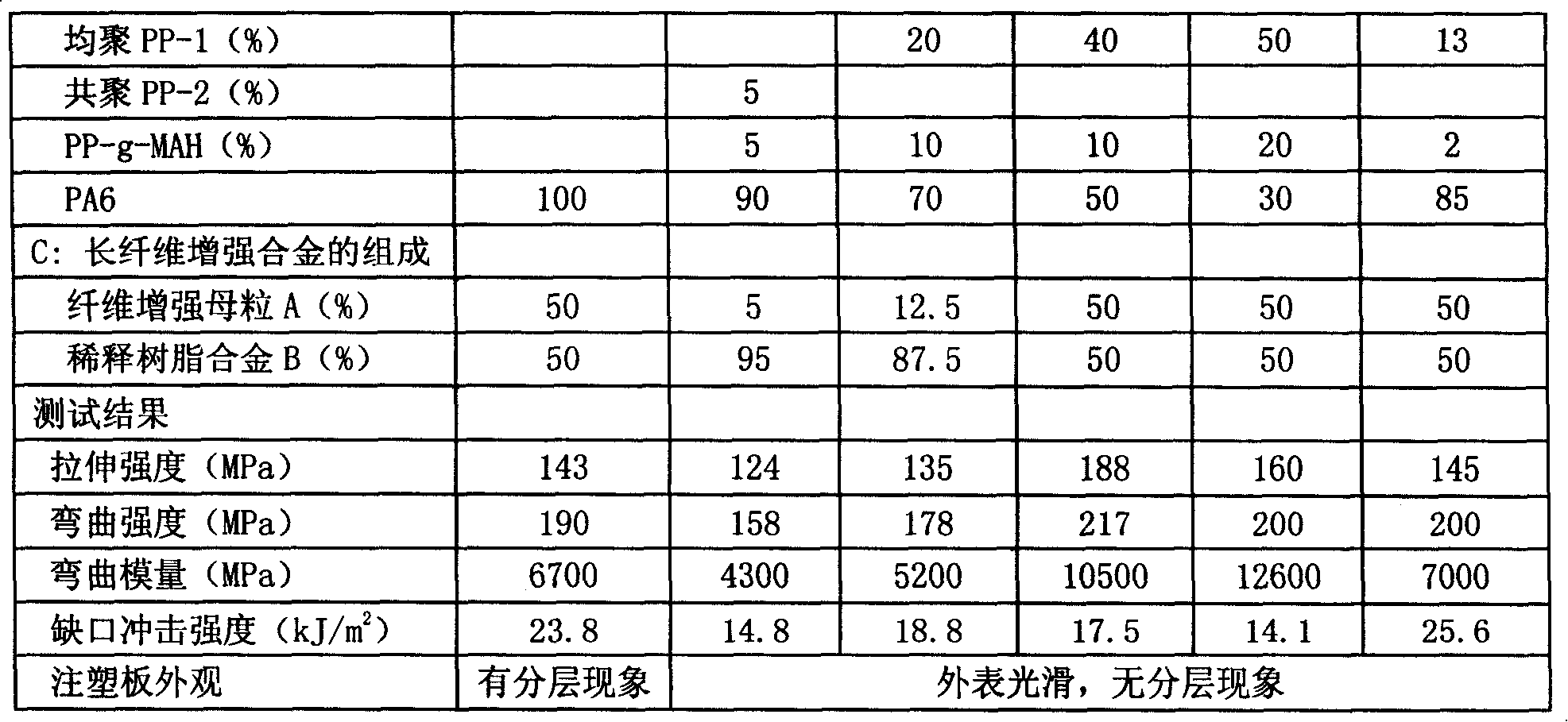

Examples

Embodiment 1

[0027] Mix 59kg of homopolypropylene resin PP-1 and 1kg of maleic anhydride grafted polypropylene (PP-g-MAH), and use pultrusion to make a long glass fiber reinforced polypropylene composite resin with a glass fiber content of 40kg Masterbatch, the glass fibers are arranged parallel to each other along the length direction of the masterbatch particles, and the length is the same as that of the masterbatch particles, which is 6mm; the processing temperature is 210°C.

[0028] At the same time, 20kg of homopolypropylene resin PP-1, 10kg of maleic anhydride grafted polypropylene (PP-g-MAH) and 70kg of nylon 6 (PA6) were mixed, and melt kneaded and blended using a twin-screw extruder , to obtain polypropylene / nylon alloy diluted resin.

[0029] Then, 95kg of long glass fiber reinforced polypropylene masterbatch was blended with 5kg of polypropylene / nylon alloy diluted resin, and injection molded into a standard mechanical test sample for testing. The test results are shown in Tabl...

Embodiment 2

[0036] Mix 45kg of homopolypropylene resin PP-1 and 5kg of maleic anhydride grafted polypropylene (PP-g-MAH), and use the pultrusion process to make a long glass fiber reinforced polypropylene composite resin with a glass fiber content of 50kg Masterbatch, the glass fibers are arranged parallel to each other along the length direction of the masterbatch particles, and the length is the same as that of the masterbatch particles, which is 12mm; the processing temperature is 250°C.

[0037] At the same time, 20kg of homopolypropylene resin PP-1, 10kg of maleic anhydride grafted polypropylene (PP-g-MAH) and 70kg of nylon 66 (PA66) were mixed, and melt kneaded and blended using a twin-screw extruder. , to obtain polypropylene / nylon alloy diluted resin.

[0038] Then, 80kg of long glass fiber reinforced polypropylene masterbatch was blended with 20kg of polypropylene / nylon alloy diluted resin, and injection molded into a standard mechanical test sample for testing. The test results ...

Embodiment 3

[0040]Mix 40kg of homopolypropylene resin PP-1 and 5kg of maleic anhydride grafted polypropylene (PP-g-MAH), and use the pultrusion process to make a long glass fiber reinforced polypropylene composite resin with a glass fiber content of 50kg Masterbatch, the glass fibers are arranged parallel to each other along the length direction of the masterbatch particles, and the length is the same as that of the masterbatch particles, which is 12mm; the processing temperature is 250°C.

[0041] At the same time, 20kg of homopolypropylene resin PP-1, 10kg of maleic anhydride grafted polypropylene (PP-g-MAH) and 70kg of nylon 6 (PA6) were mixed, and melt kneaded and blended using a twin-screw extruder , to obtain polypropylene / nylon alloy diluted resin.

[0042] Then, 80kg of long glass fiber reinforced polypropylene masterbatch was blended with 20kg of polypropylene / nylon alloy diluted resin, and injection molded into a standard mechanical test sample for testing. The test results are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com