Nutraceutical fractions from cereal grains

A grain, selected technology, applied in the field of nutrition, can solve problems such as increasing problems and difficult removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

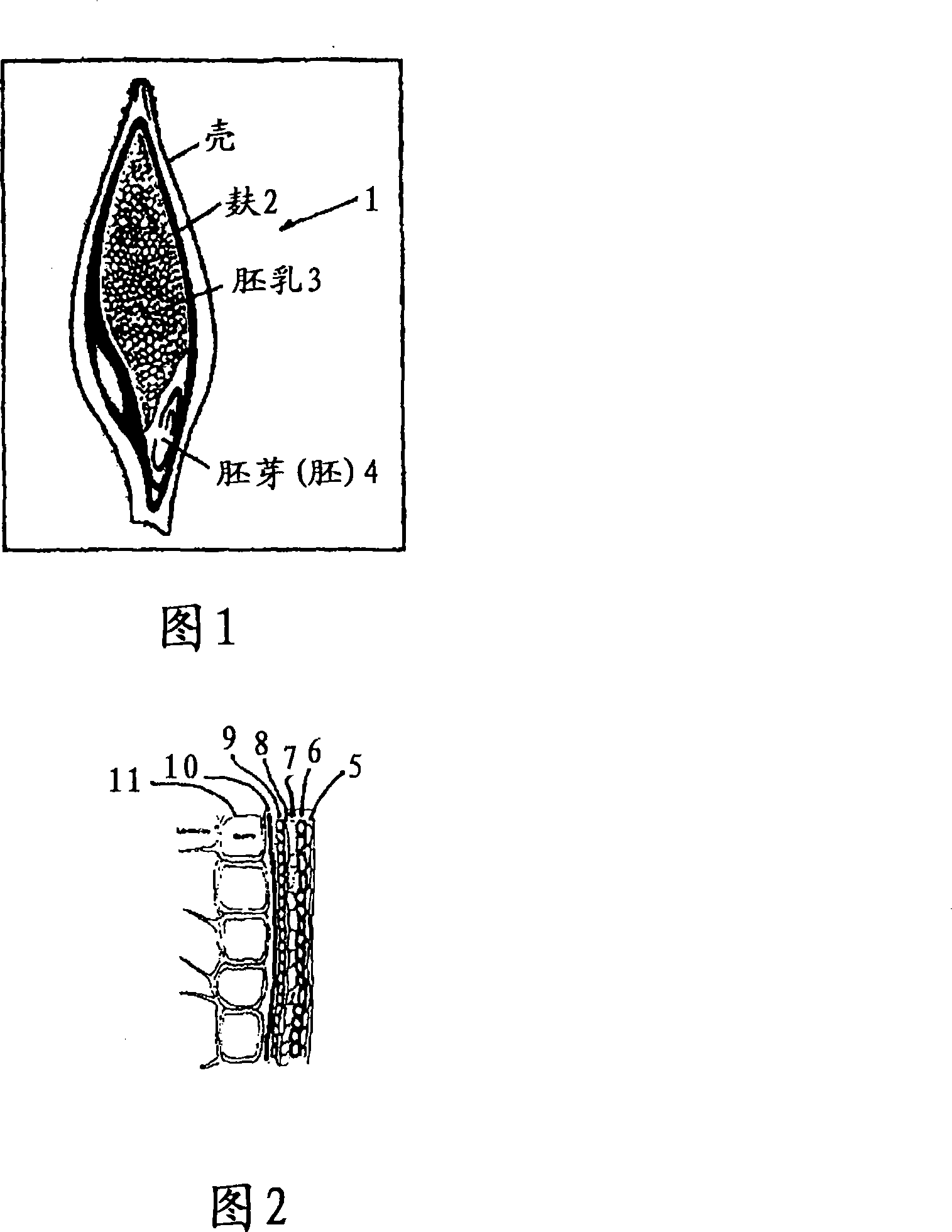

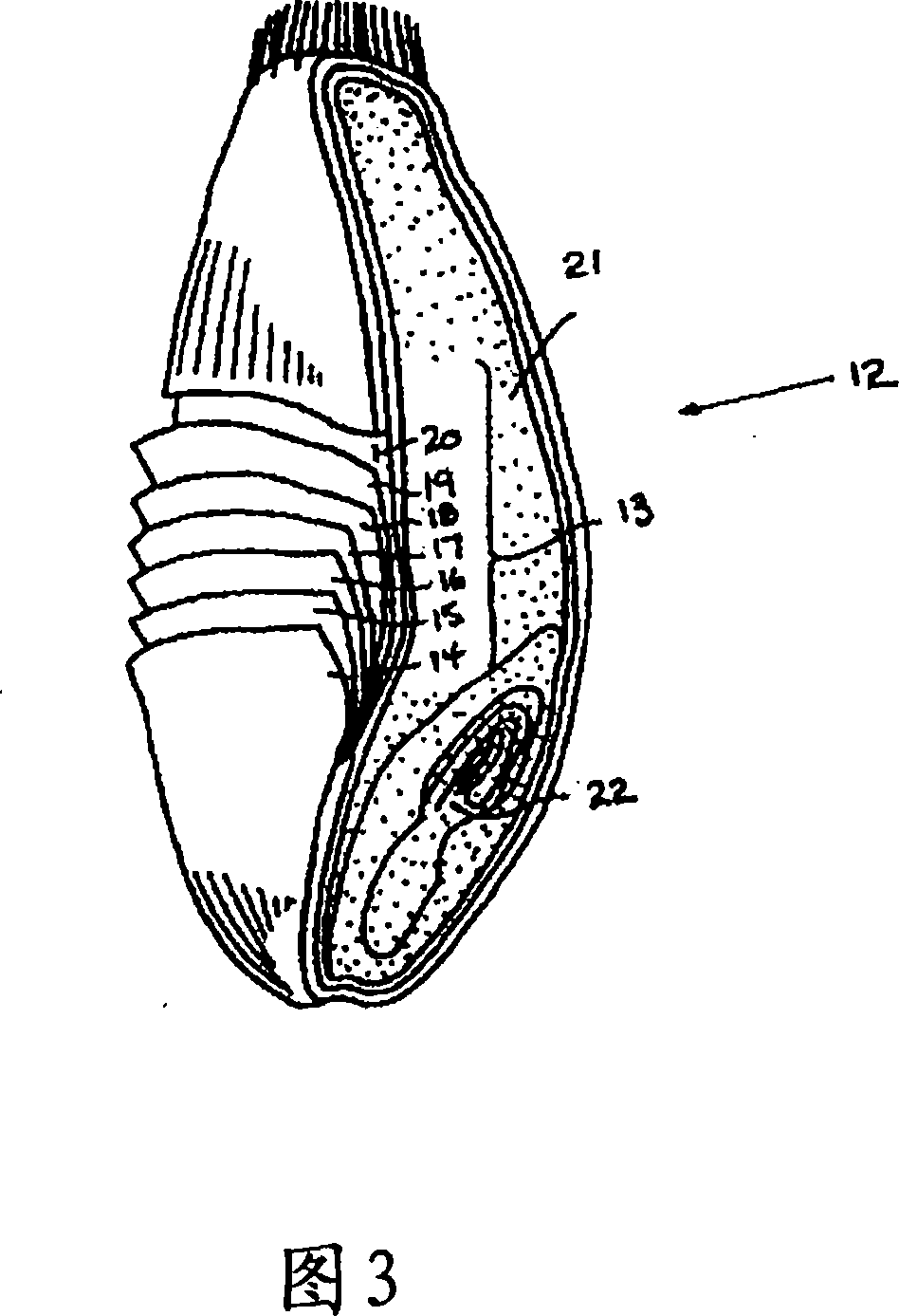

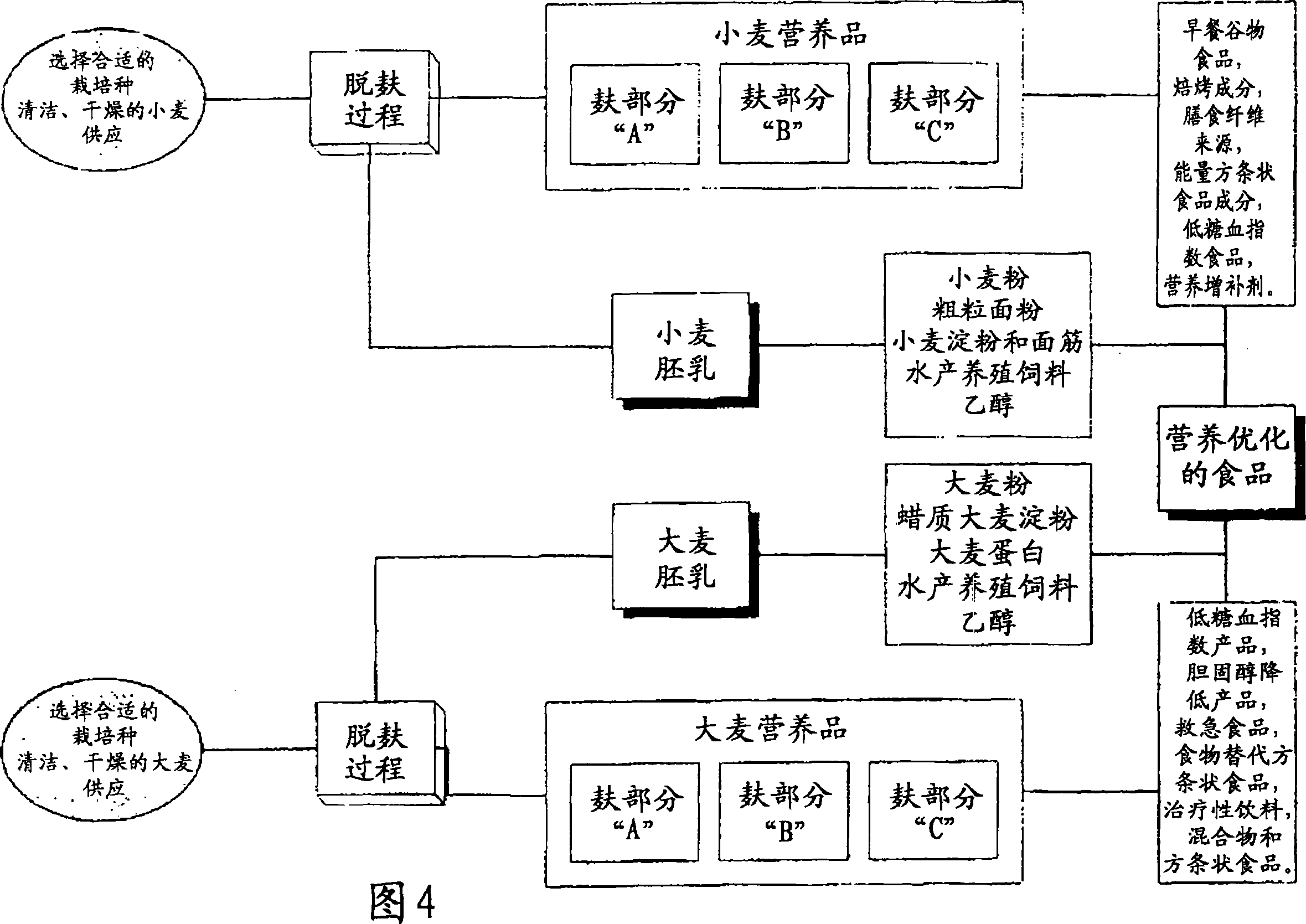

[0027]The outer bran of a grain is made up of different cell layers with different chemical and physical properties. A barley grain 1 , for example, is schematically shown in FIG. 1 . Barley can be a regular variety with a husk or husk that encloses the barley kernel, or a huskless variety. In either case, the barley kernel 1 has an outer bran layer 2 surrounding the endosperm 3 and germ 4 . As shown schematically in Figure 2, the outer bran of barley has seven distinct layers: epidermis 5, dermis 6, mold cells 7, powder tube cells 8, seed coat 9, nucellus tissue 10, and aleurone cells 11. Barley has been shown to have many valuable health and nutritional properties, including promoting health and improving the function of the digestive and immune systems. USDA clinical trials have shown that consumption of barley containing beta glucan significantly improved several cardiovascular risk factors in men with high chol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com