Advanced chemical mechanical polishing system with smart endpoint detection

A boundary point and workpiece fixture technology, applied in grinding/polishing equipment, control of workpiece feed motion, manufacturing tools, etc., can solve problems such as difficulty in reducing thickness and plane shape, and achieve optimization of polishing, saving time and cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

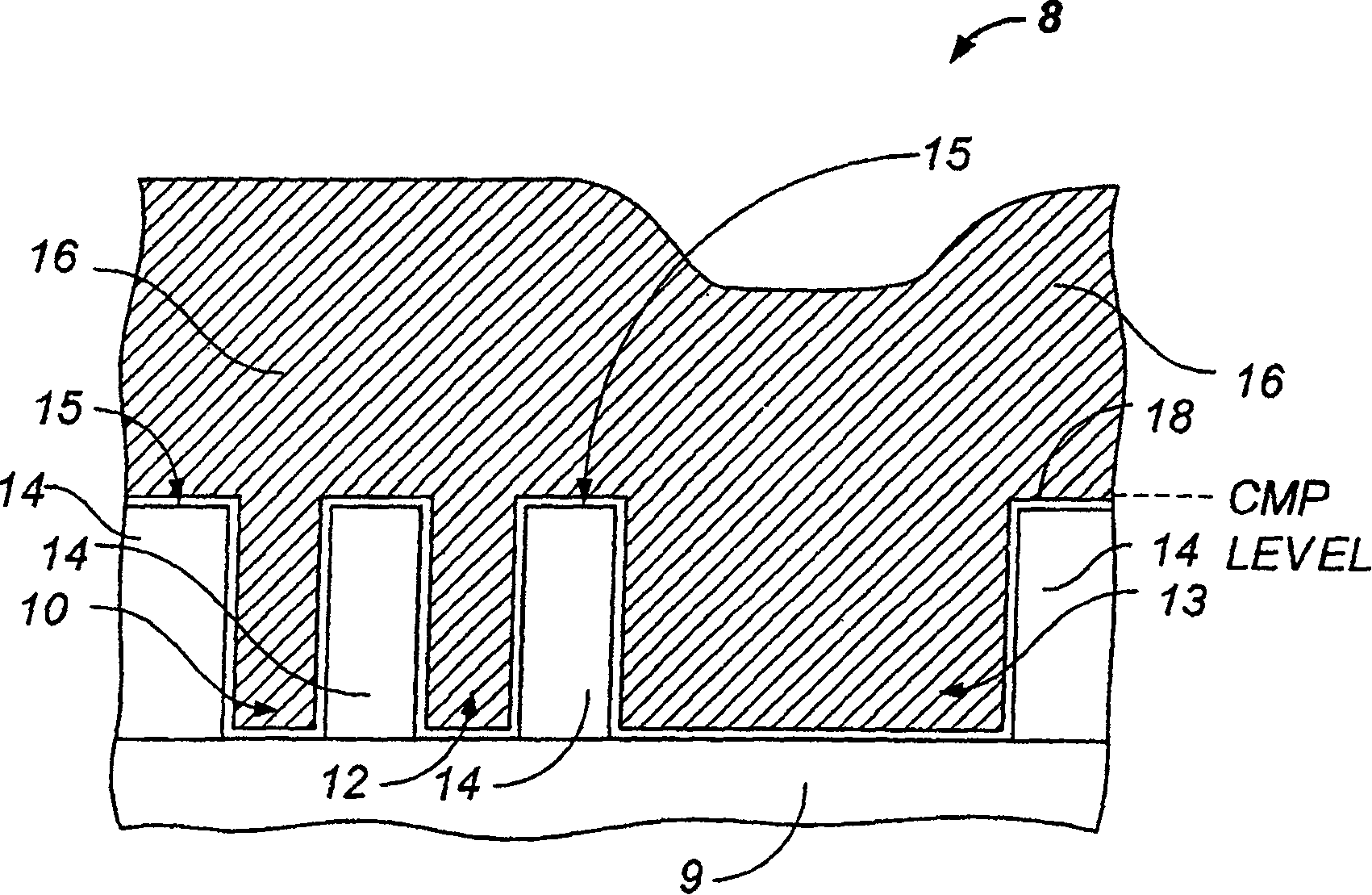

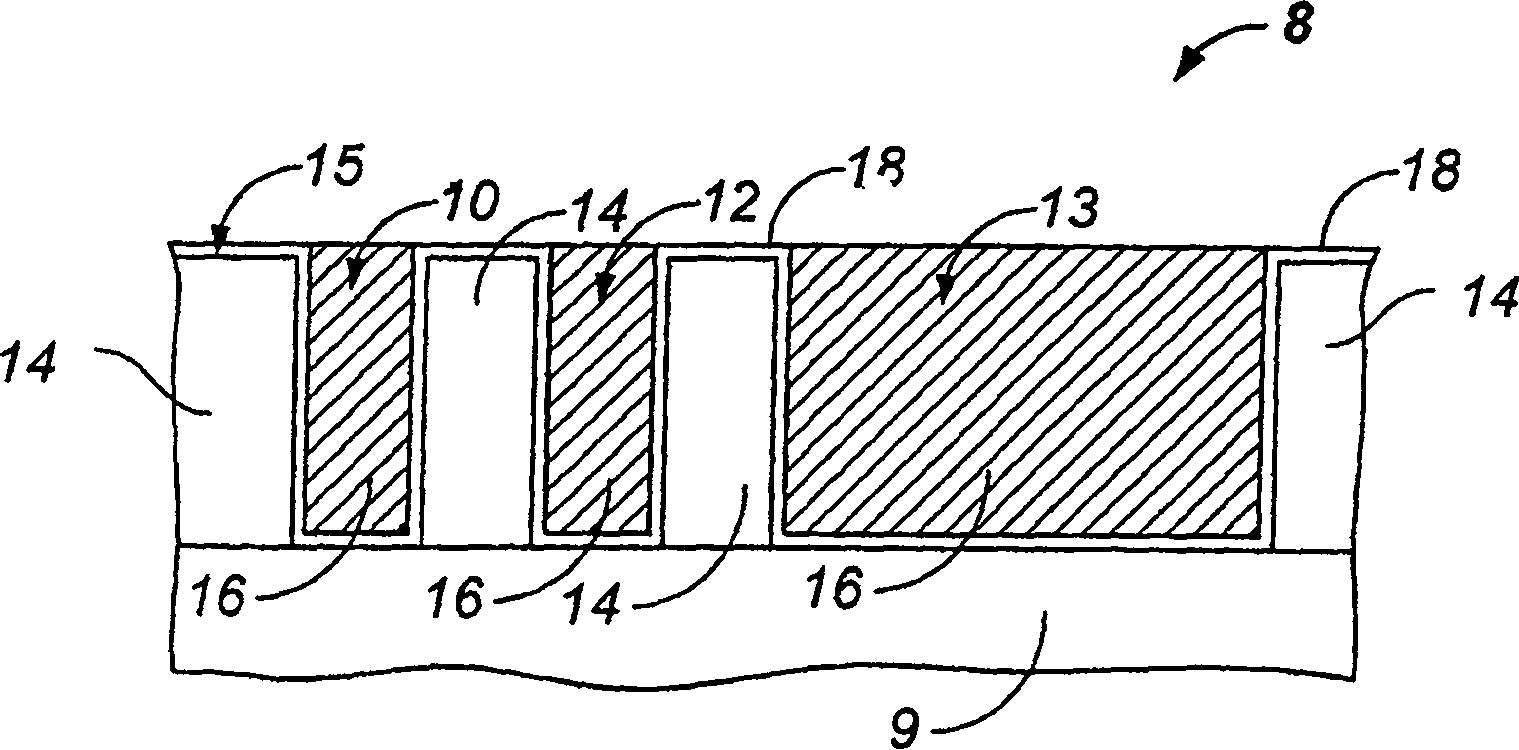

[0067] As described below, the present invention provides a method and system for in situ boundary point detection using a material removal method such as CMP. The following description refers to the drawings, and the same reference numerals in the drawings represent the same components.

[0068] A. Boundary point detection system

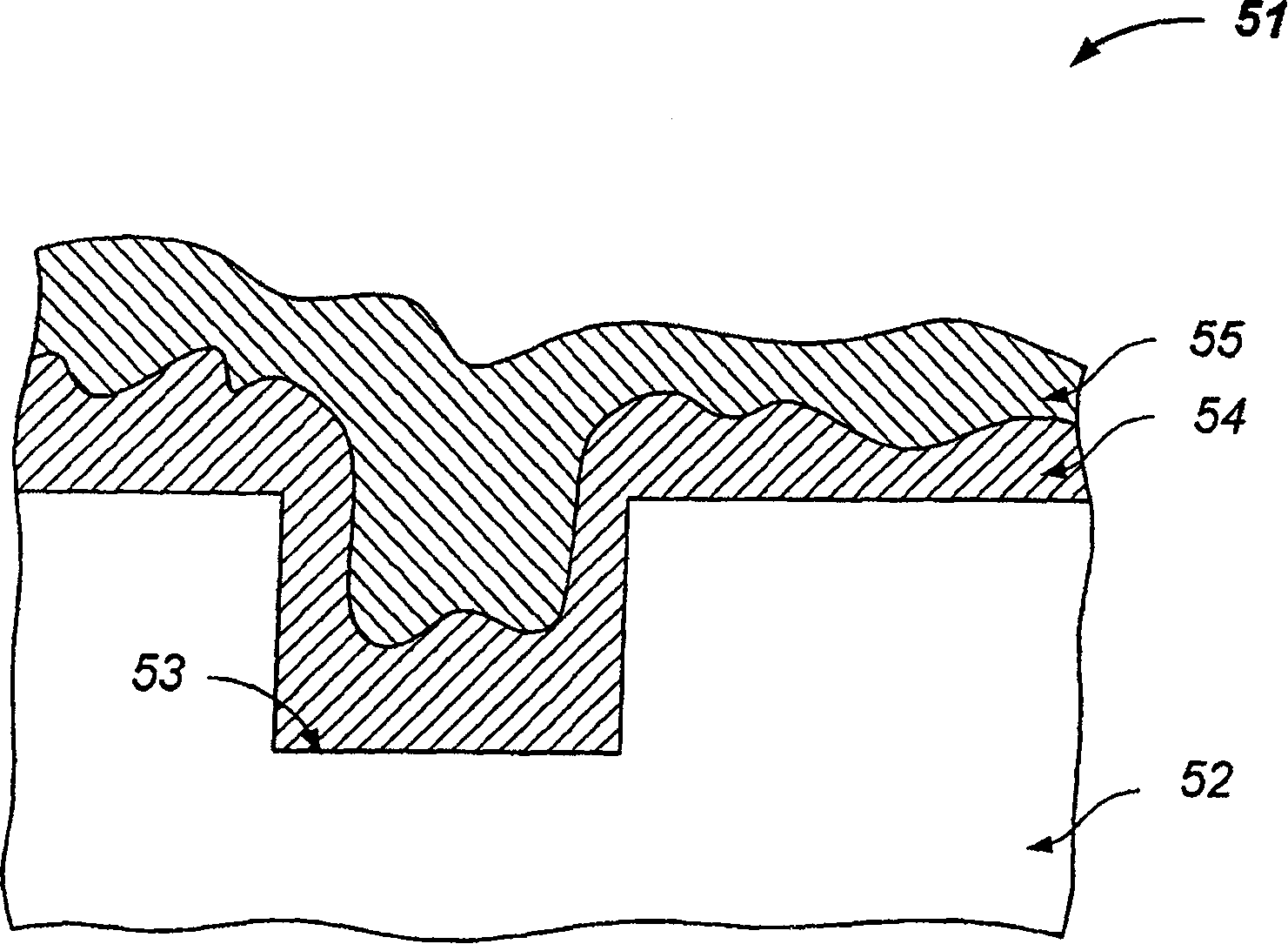

[0069] figure 2 An exemplary chemical mechanical polishing (CMP) apparatus 100 including a polishing element 102 and a carriage 104 is shown. The polishing element can be a polishing belt, a polishing pad or other types of polishing elements. Polishing element 102 includes an upper or working surface 106 and a bottom surface 108 . The bottom surface 108 of the polishing element is disposed in tension on a support plate 109, such as a platen. The polishing element and carrier are positioned such that the surface of the workpiece abuts the polishing element, ie the surface of the workpiece may be in close proximity to or contact the polishing el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com