Method for reduction of organic chlorinated compound in cement manufacture plant, and cement manufacture plant

A technology for production equipment and compounds, applied in the direction of solid waste removal, etc., can solve problems such as banning PCB manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] The best way to practice the invention

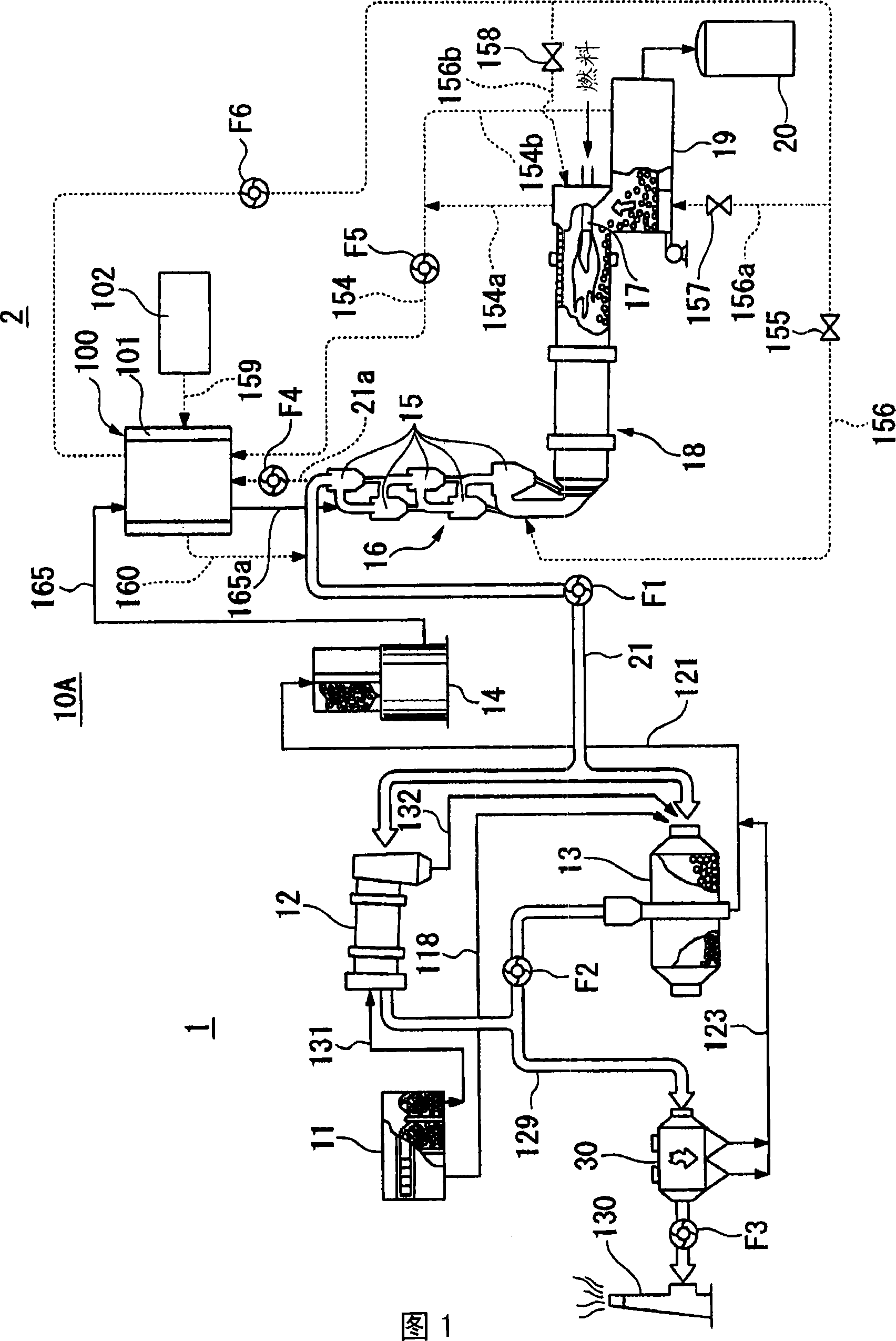

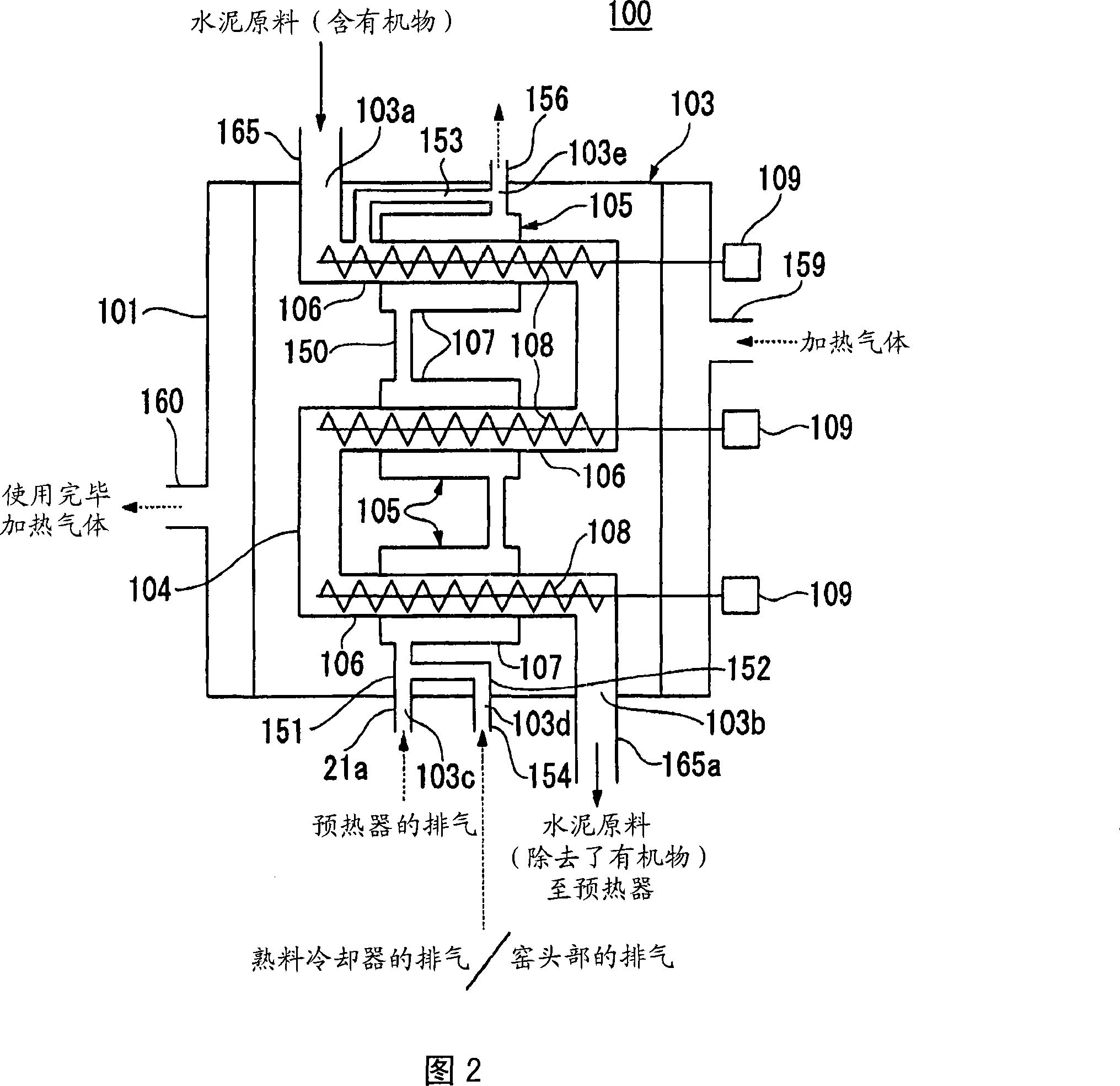

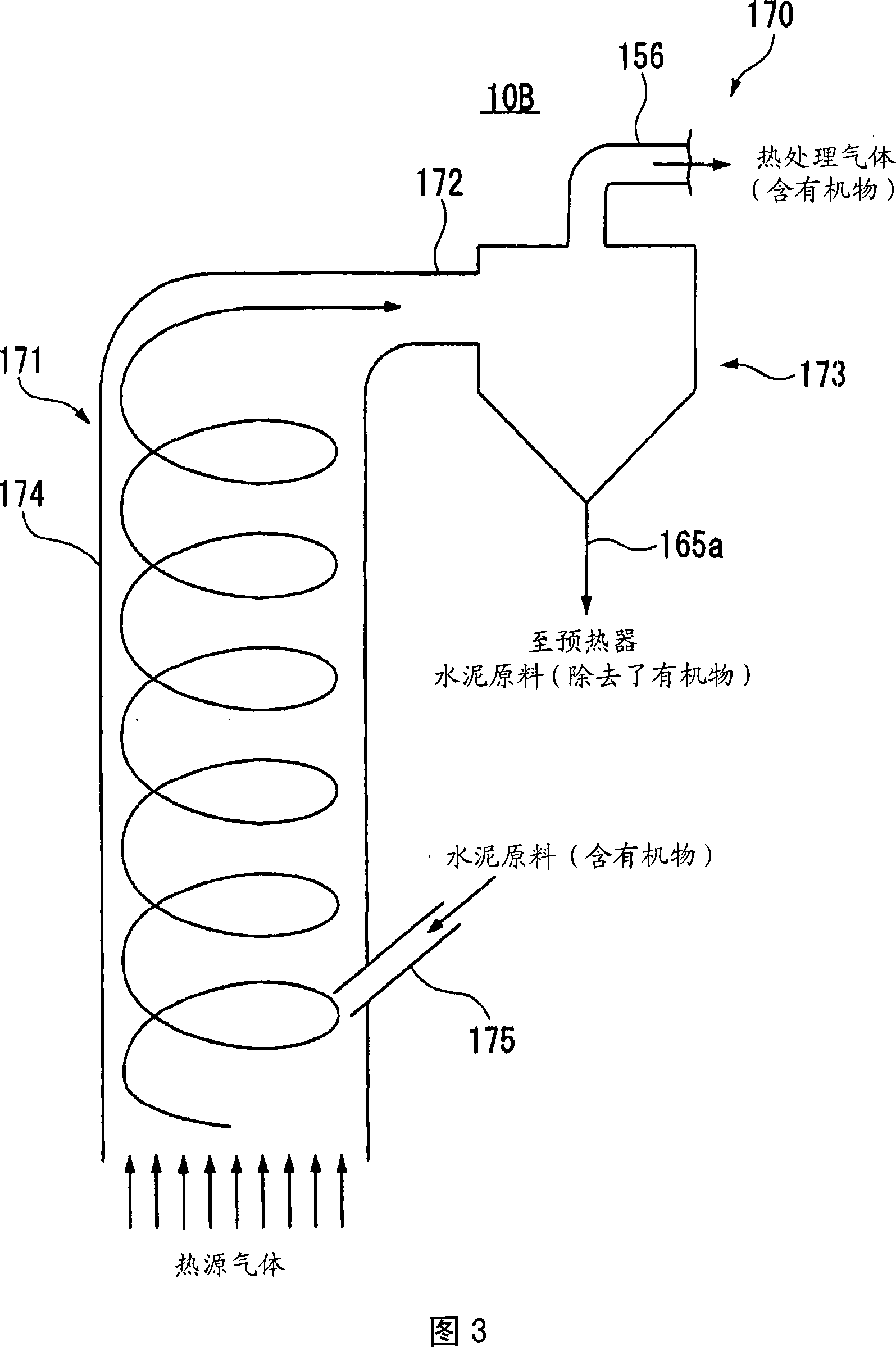

[0098] Referring to FIG. 1 and FIG. 2 , the method for reducing organic chlorine compounds in cement production equipment and the first embodiment of the cement production equipment of the present invention will be described.

[0099] As shown in FIG. 1 , a cement production facility 10A of the present embodiment includes a raw material step part 1 for pulverizing cement raw materials and a calcining step part 2 for calcining the pulverized cement raw materials.

[0100] The raw material processing unit 1 includes a raw material storage 11 , a raw material dryer 12 , a raw material mill 13 , a storage silo 14 , and an electric dust collector (dust collector) 30 . The raw material storage 11 respectively stores limestone, clay, silica, and iron raw materials as cement raw materials. The raw material dryer 12 heats and dries the cement raw material with a large water content. The raw material mill 13 grinds the cement raw materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com