Lip type seal

A technology for sealing fluid and lips, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of reduced sealing performance, poor creep characteristics, damage, etc., and achieve the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

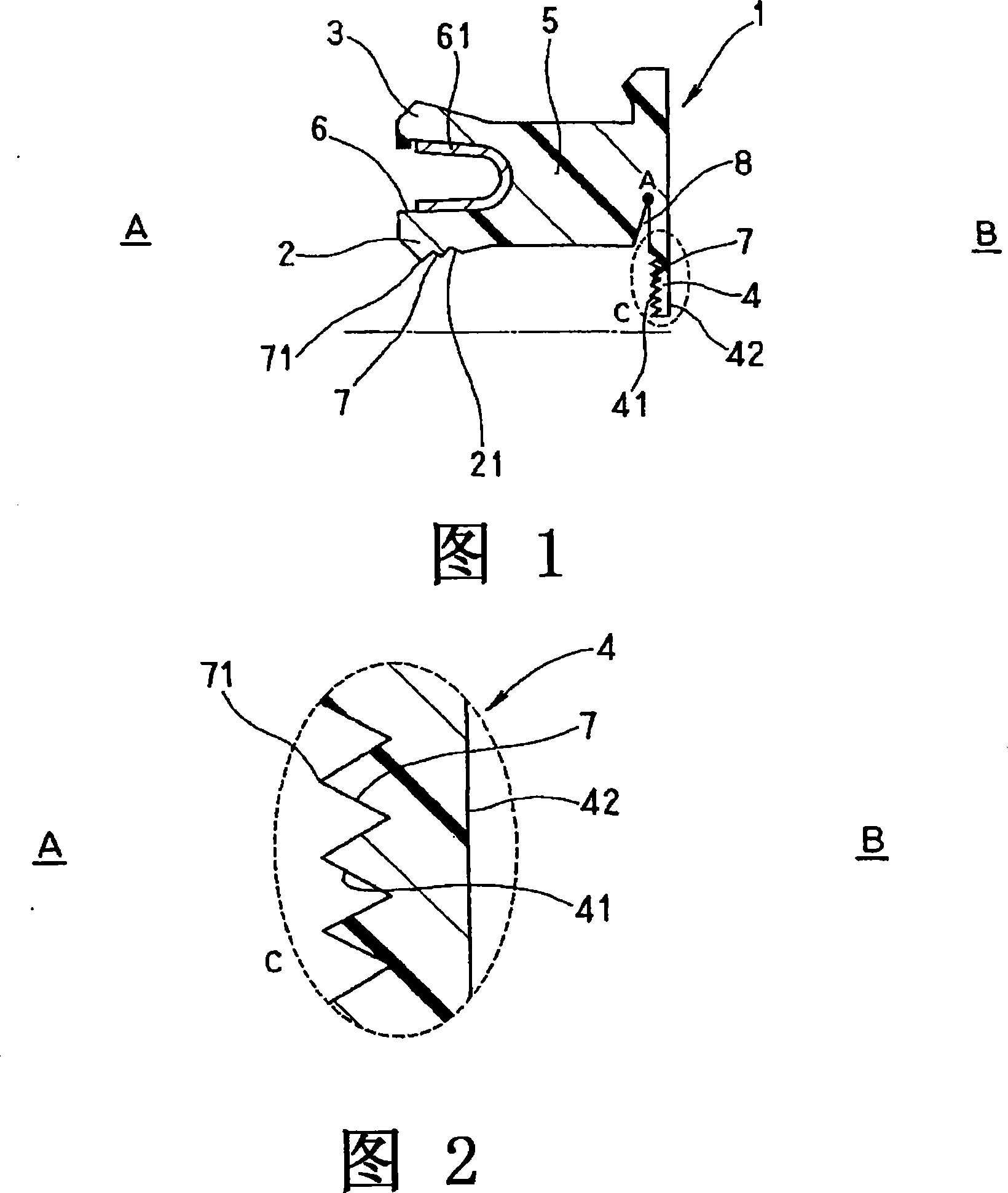

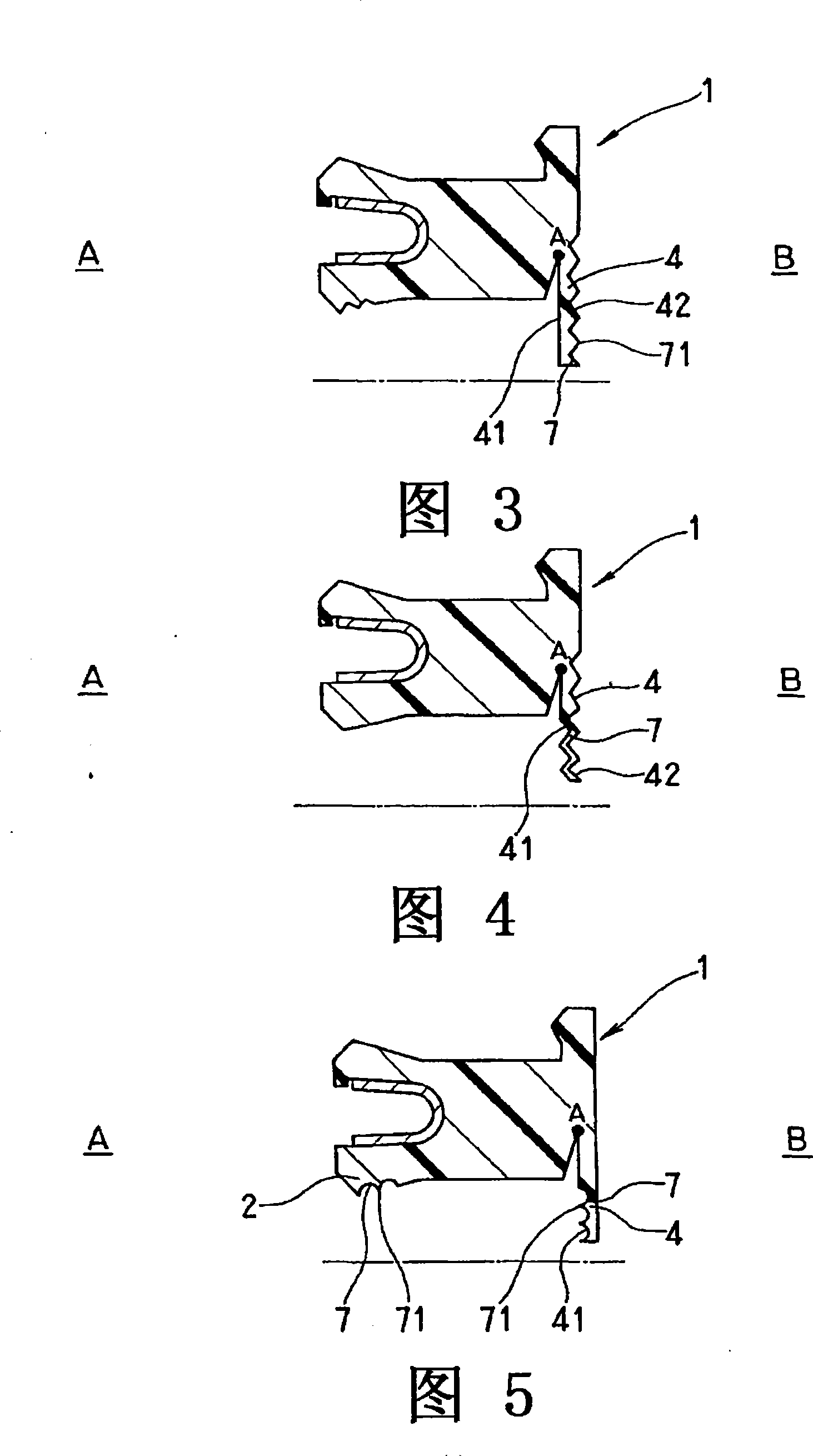

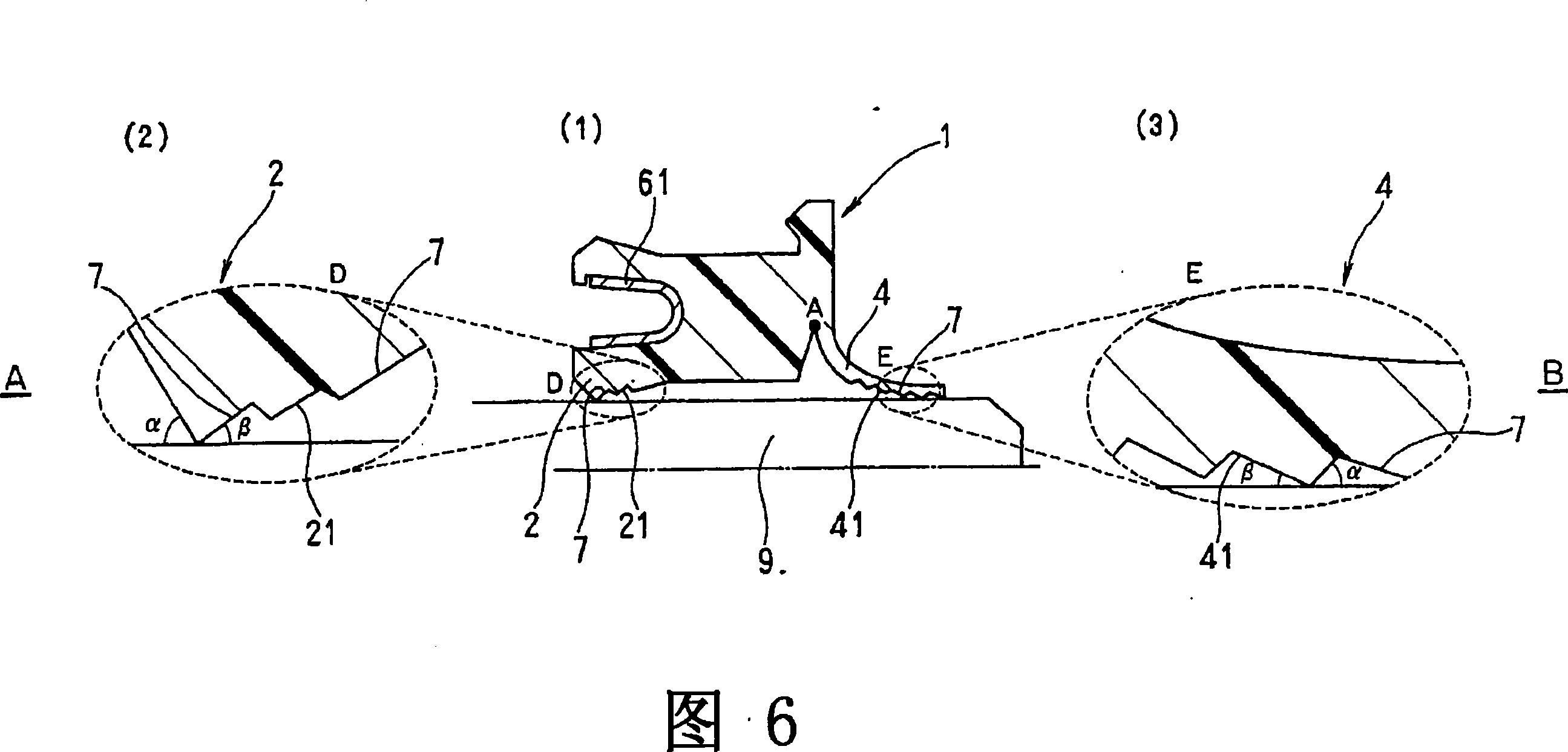

[0043] The preferred embodiments of the present invention will be illustrated below with reference to the accompanying drawings. However, unless the scope of the present invention is particularly limited, it is not limited to the content described in this embodiment.

[0044] The lip seal according to the embodiment of the present invention is provided in the annular space between the bracket and the shaft.

[0045] As shown in Fig. 1, the lip seal 1 according to Embodiment 1 of the present invention includes a sealing body 5 made of resin PTFE and a spring 61 installed in a cylindrical recess 6 with a U-shaped cross section; The body 5 is integrally formed by the following parts: the inner peripheral lip 2 and the outer peripheral lip 3, having a substantially cylindrical recess 6 facing the opening of the first sealing fluid side A, and being arranged on the inner and outer peripheries of the cylindrical recess 6 , in sliding contact with the shaft and the bracket; the plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com