Method for multi-exposure beam lithography device

A technology of electromagnetic radiation and actual position, which is applied in photoplate-making process exposure devices, microlithography exposure equipment, optics, etc., and can solve problems such as increased CD errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

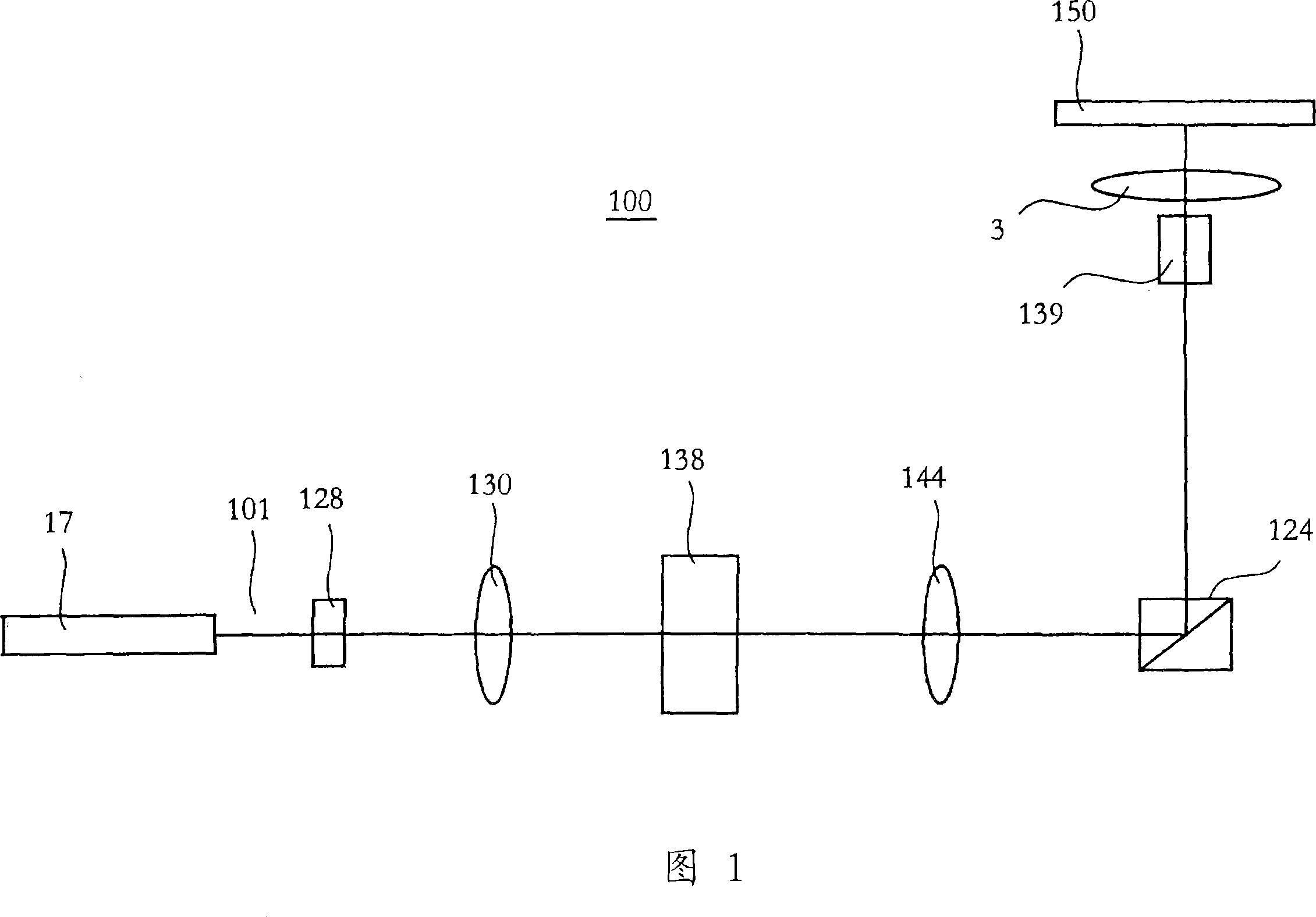

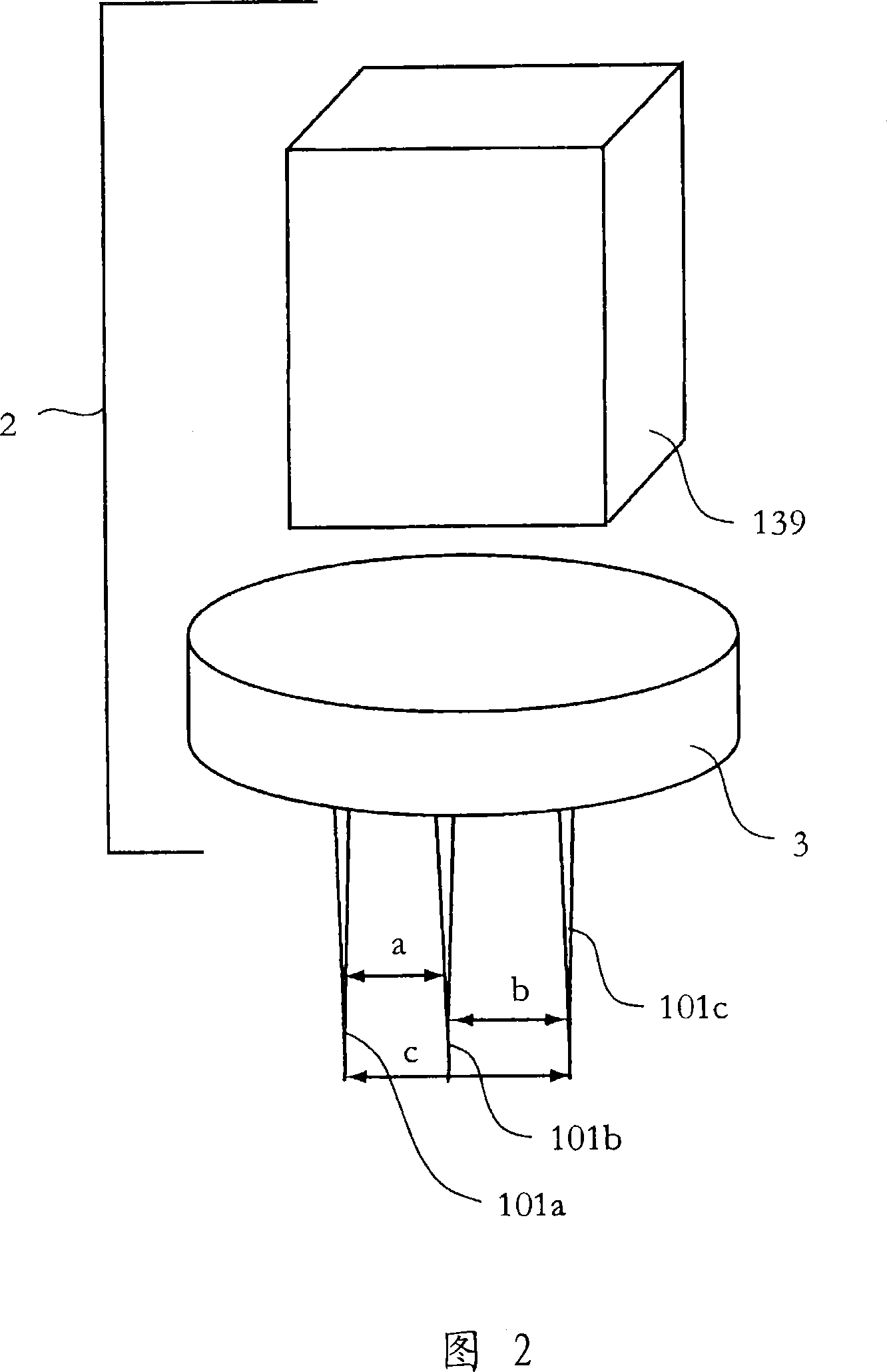

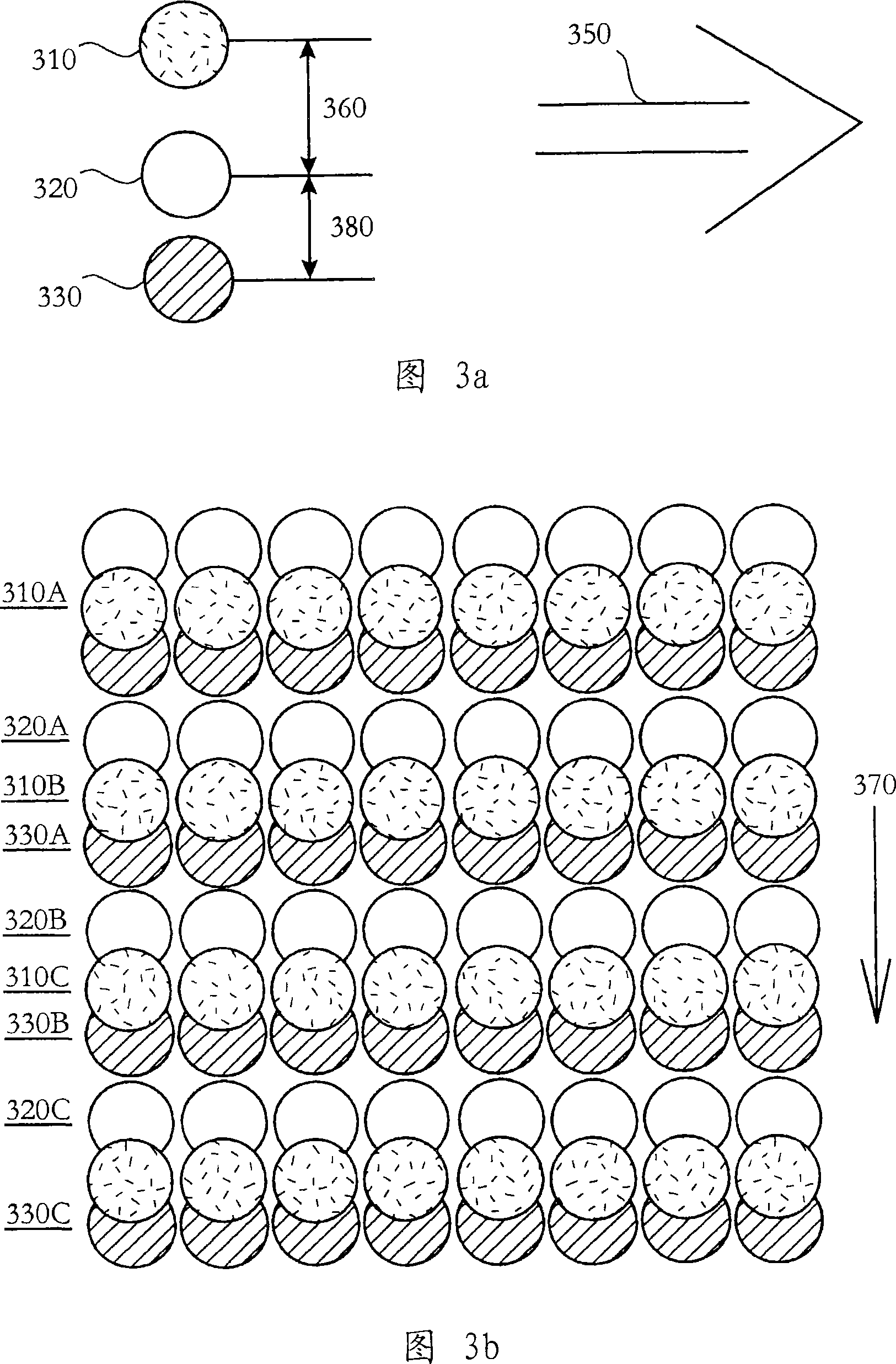

[0029] The present invention will be described in detail below with reference to the accompanying drawings. The preferred embodiments are described to explain the invention, not to limit the scope of the invention defined by the claims. Those of ordinary skill in the art will recognize many equivalent variations in the description that follows.

[0030] Further, the preferred embodiment is described with reference to a laser scanning pattern generator. It is obvious to those skilled in the art that any exposure means can be equally applied, such as light from IR to EUV, x-rays, or particle or atomic beams such as electrons and ions.

[0031] The invention is further described with reference to the production of masks or reticles, for example to produce periodic patterns on eg displays. It is obvious to those skilled in the art that the method and apparatus of the present invention are equally applicable to the direct writing of arbitrary patterns in masks, reticle displays o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com