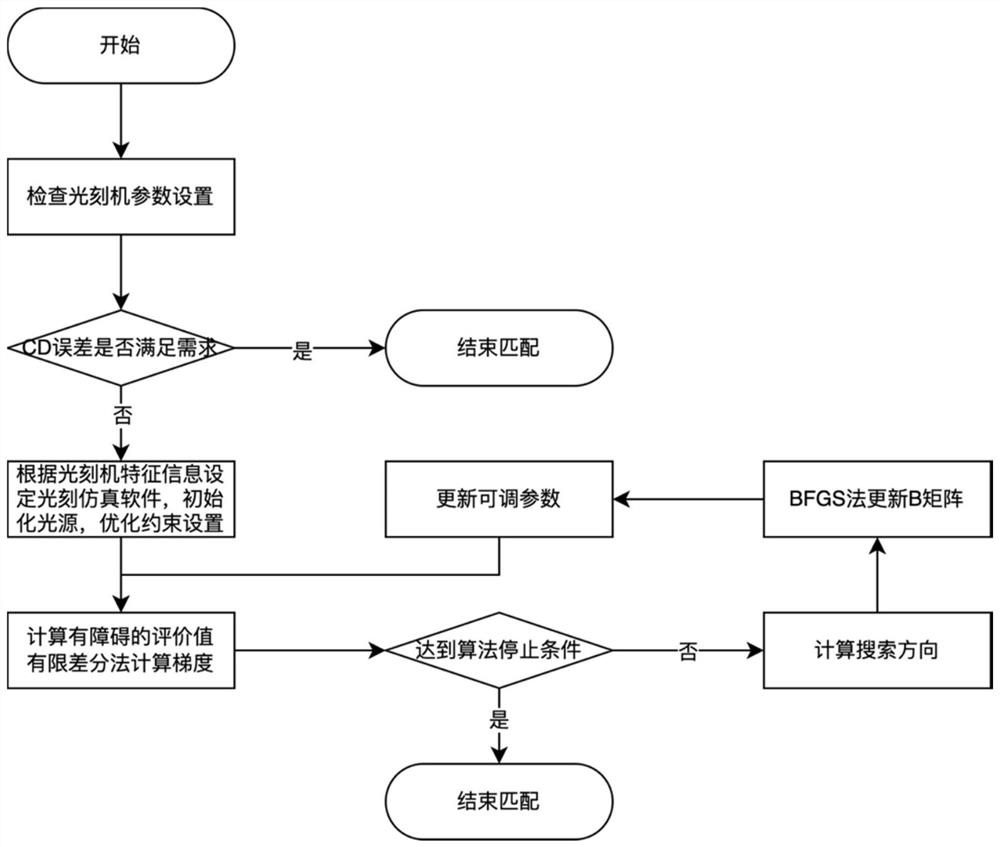

Lithography machine matching method based on BFGS quasi-Newton-interior point algorithm

A technology of interior point algorithm and matching method, which is applied in the field of lithography machine, can solve problems affecting iteration speed and information loss, and achieve the effect of accelerating iteration speed, reducing CD error, and improving matching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the examples and drawings, but the examples should not limit the protection scope of the present invention.

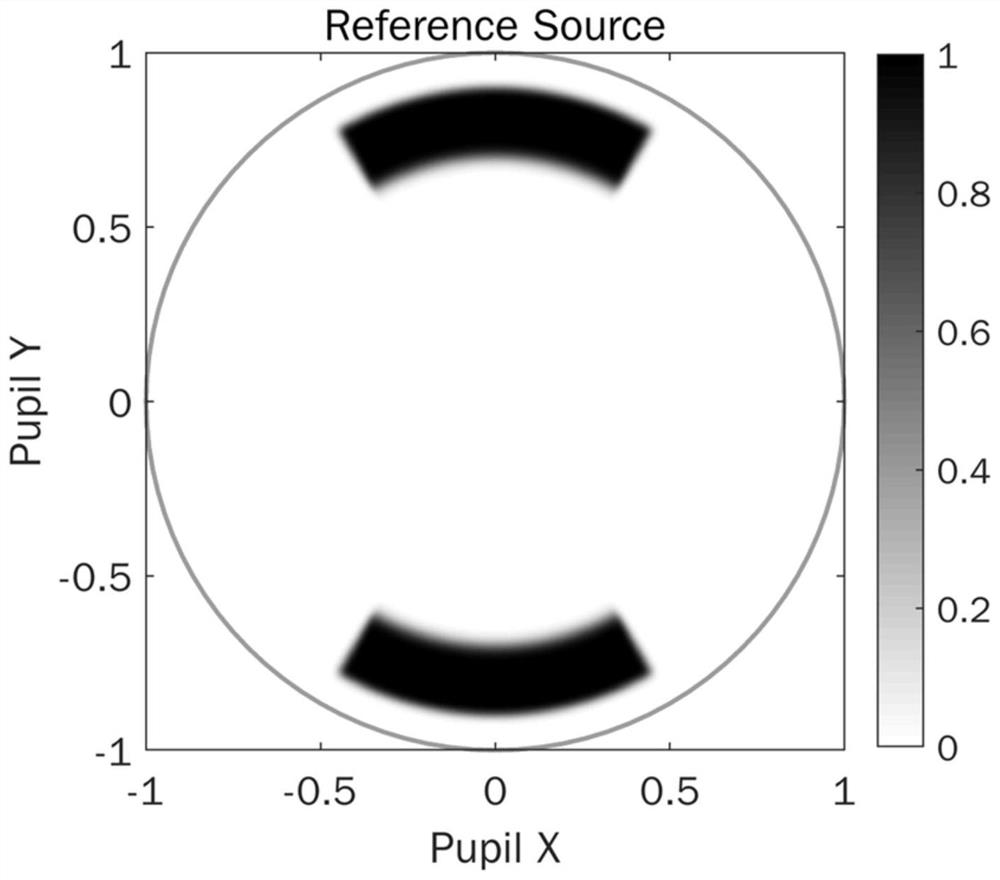

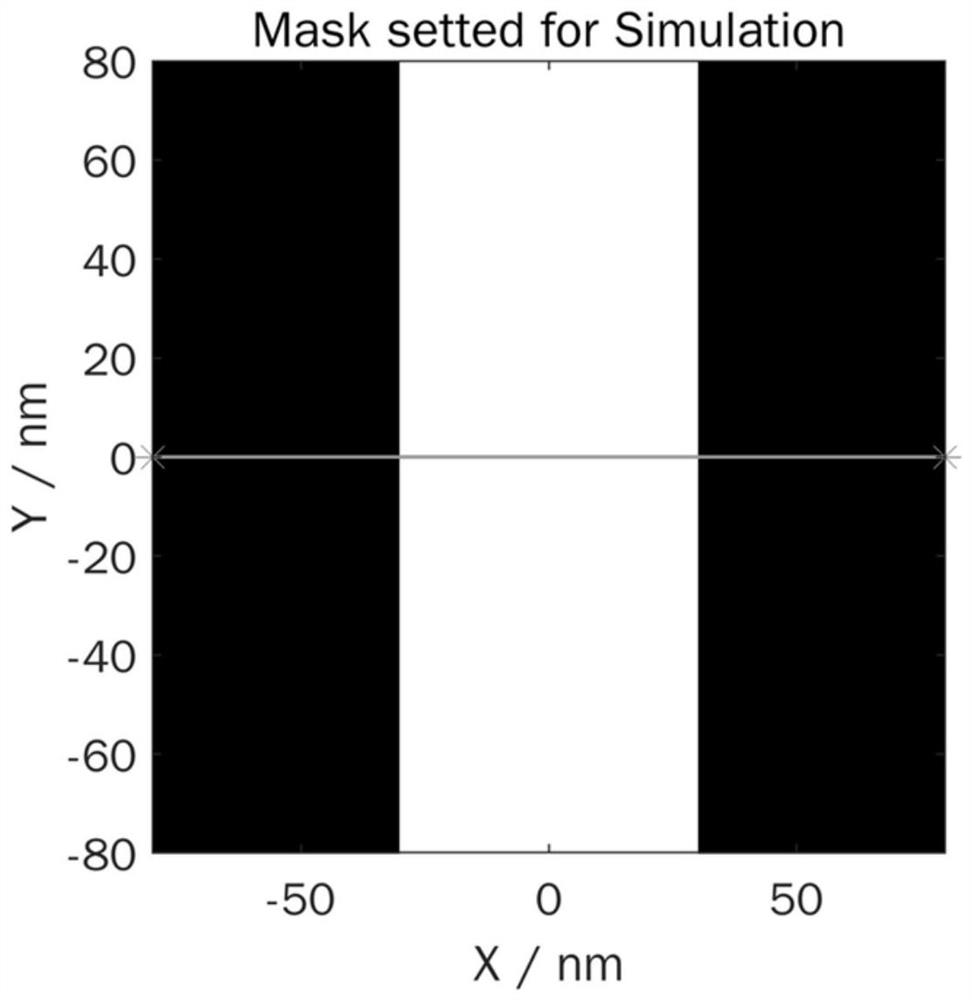

[0053] This embodiment refers to the intensity distribution of the illumination light source of the lithography machine as figure 2 As shown, the brightness value of the white area is 1, and the brightness value of the black area is 0. The test mask target pattern used is image 3 In the shown one-dimensional through-pitch line-space pattern mask, the line width of the mask pattern is 60nm, the type is a binary mask, the transmittance of the white area is 1, and the transmittance of the black area is 0. The period of the mask pattern is 160nm, 180nm, 200nm, ..., 1040nm, a total of 45, that is, M=45, and the horizontal line segment marked in the figure is the cross-sectional position of the calculated aerial image CD. Both the reference lithography machine and the to-be-matched lithograp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com