Photolithographic critical dimension control using reticle measurements

A technology of mastering and lithography, applied in the field of lithography, can solve problems such as unsatisfactory product manufacturing operations and no consideration of new mask bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

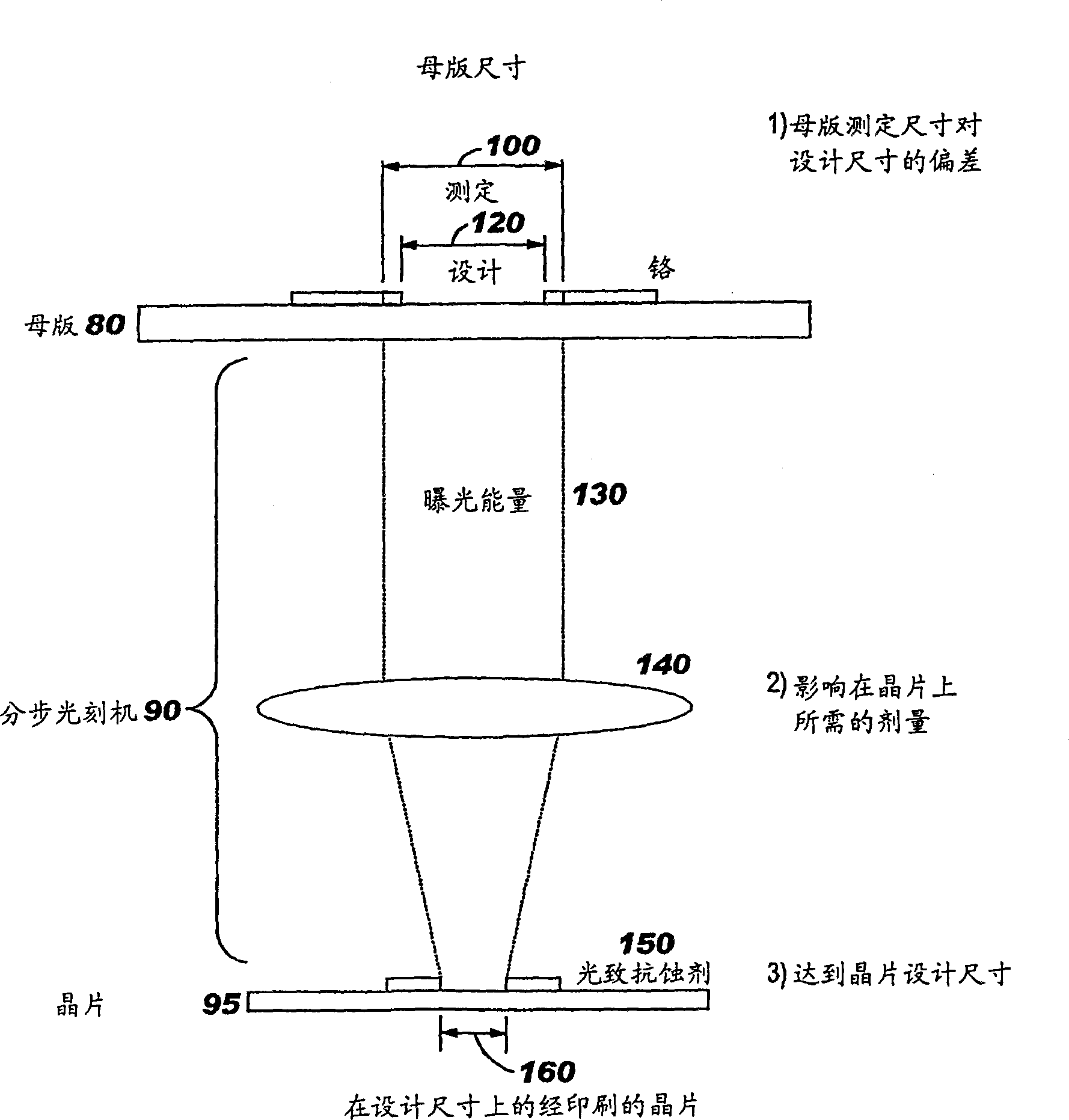

Method used

Image

Examples

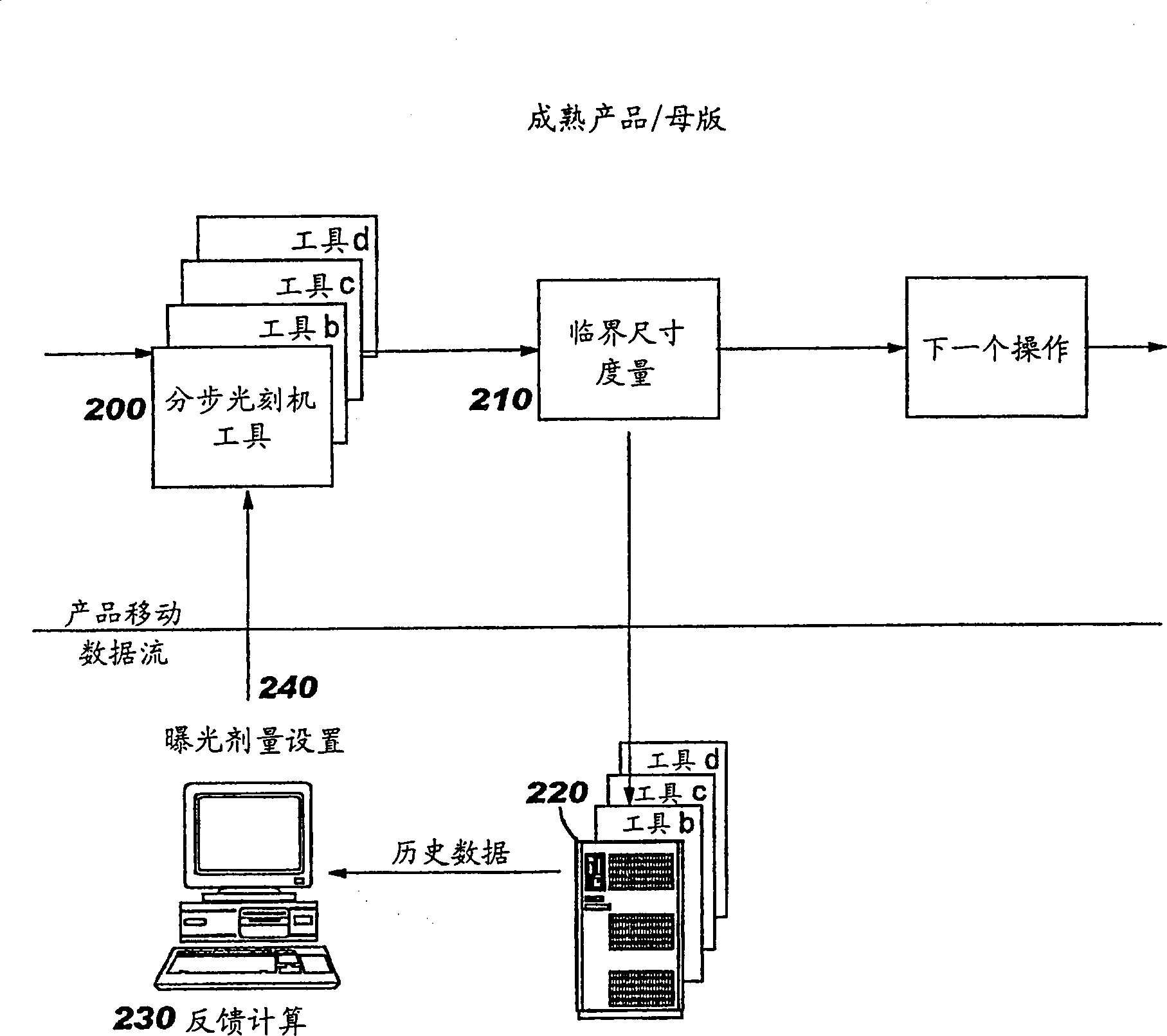

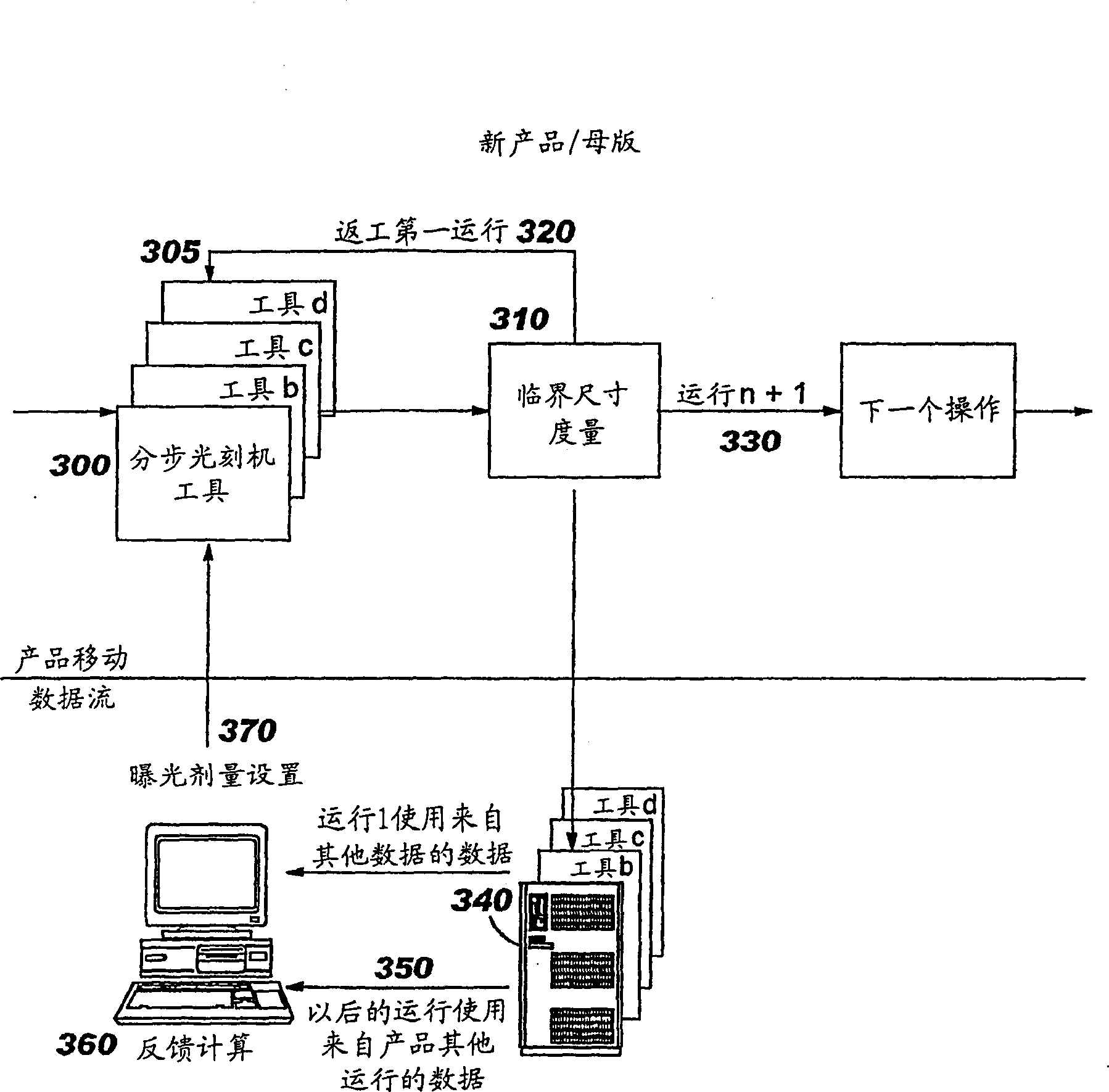

Embodiment Construction

[0036] According to the present invention, it will be described as Figure 4 The system ( 490 ) shown in FIG. 2 , wherein the metrology data obtained in the critical dimension metrology step 420 is recorded as product history data 430 . This data is algorithmically mixed with master CD data 440 of similar masters (ie masters of the same technology and level) as part of a feedback calculation 450 to adjust exposure dose settings. The initial exposure dose calculated by the present invention does not require first-run rework for making production runs. Master dimension data, master factors, historical wafer exposure conditions, and historical wafer dimension data are stored in a database for each master. These data are used when a specific master is required for a given run.

[0037] It should be noted that the present invention can be used in lithographic techniques including proximity printing as well as projection printing. However, the present invention can be used with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com