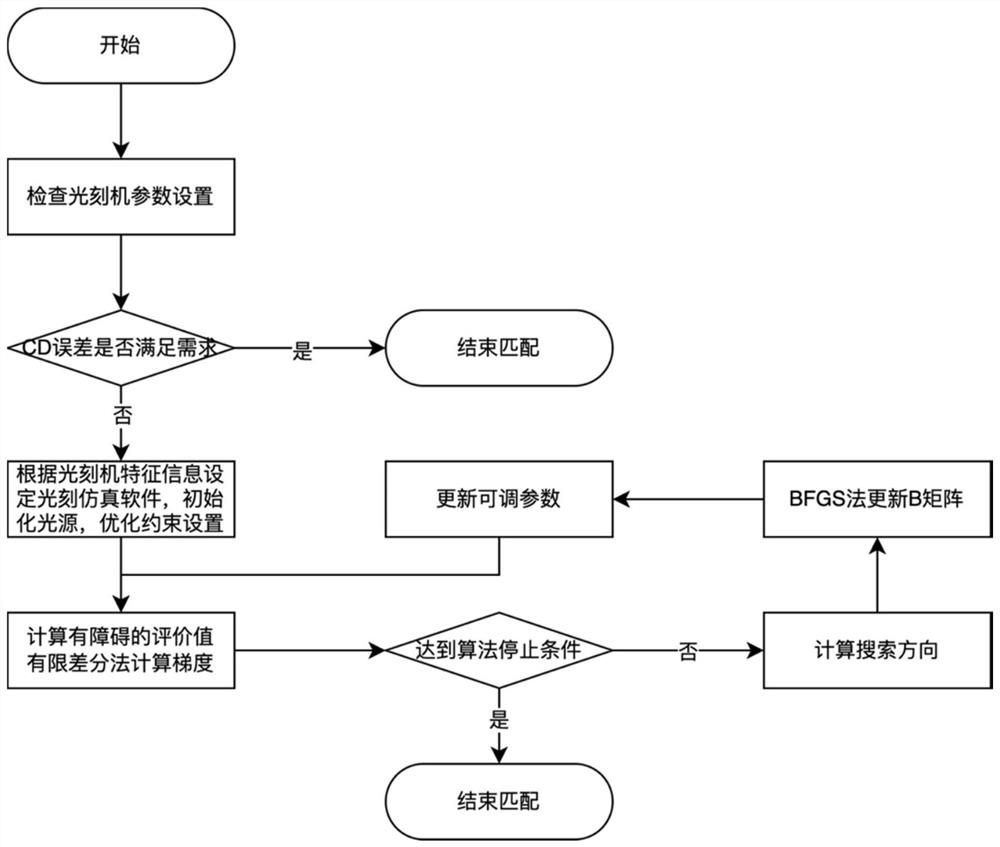

Lithography Machine Matching Method Based on BFGS Quasi-Newton-Interior Point Algorithm

An interior point algorithm and matching method technology, applied in the field of lithography machine, can solve the problems affecting the iteration speed and information loss, and achieve the effect of speeding up the iteration rate, reducing CD errors, and avoiding information loss.

Active Publication Date: 2022-05-31

SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In fact, in the process of matching by adjusting the light source of the lithography machine, the parameters of the light source can only be adjusted within a limited range, and the Newton method or the least square method used in the aforementioned technology is usually used to solve unconstrained optimization problems , there is a possibility of information loss during the algorithm iteration, which affects the iteration speed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0061]

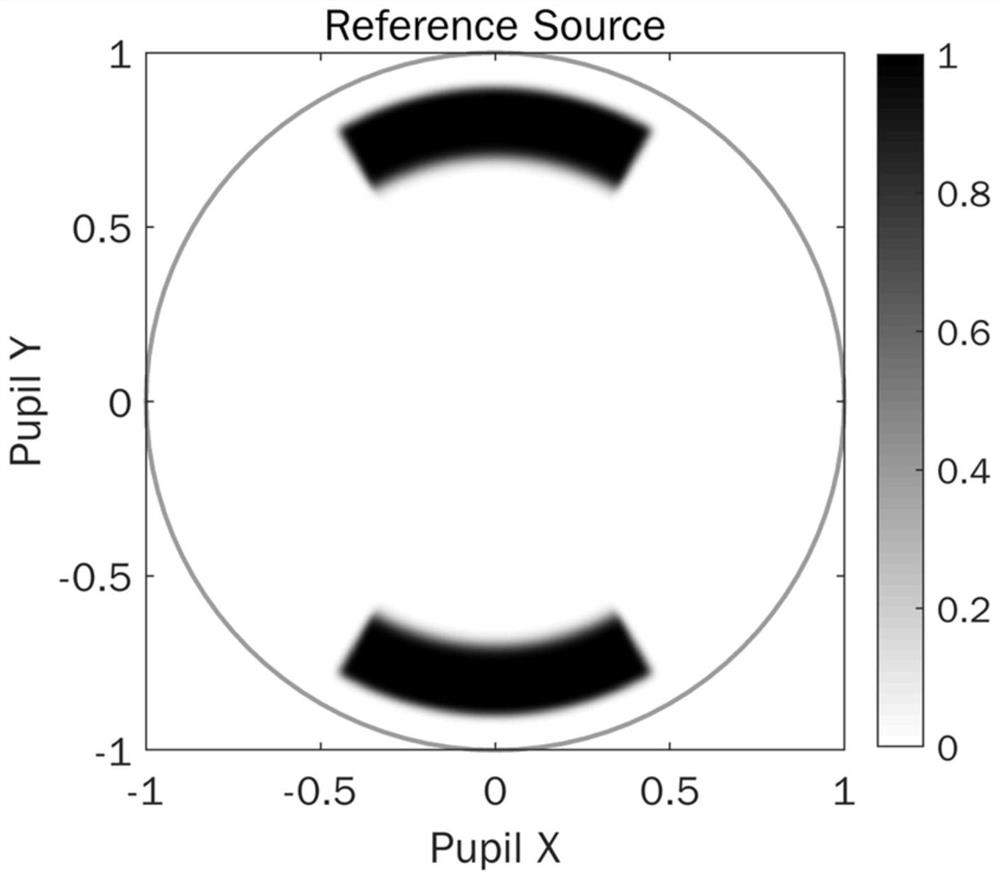

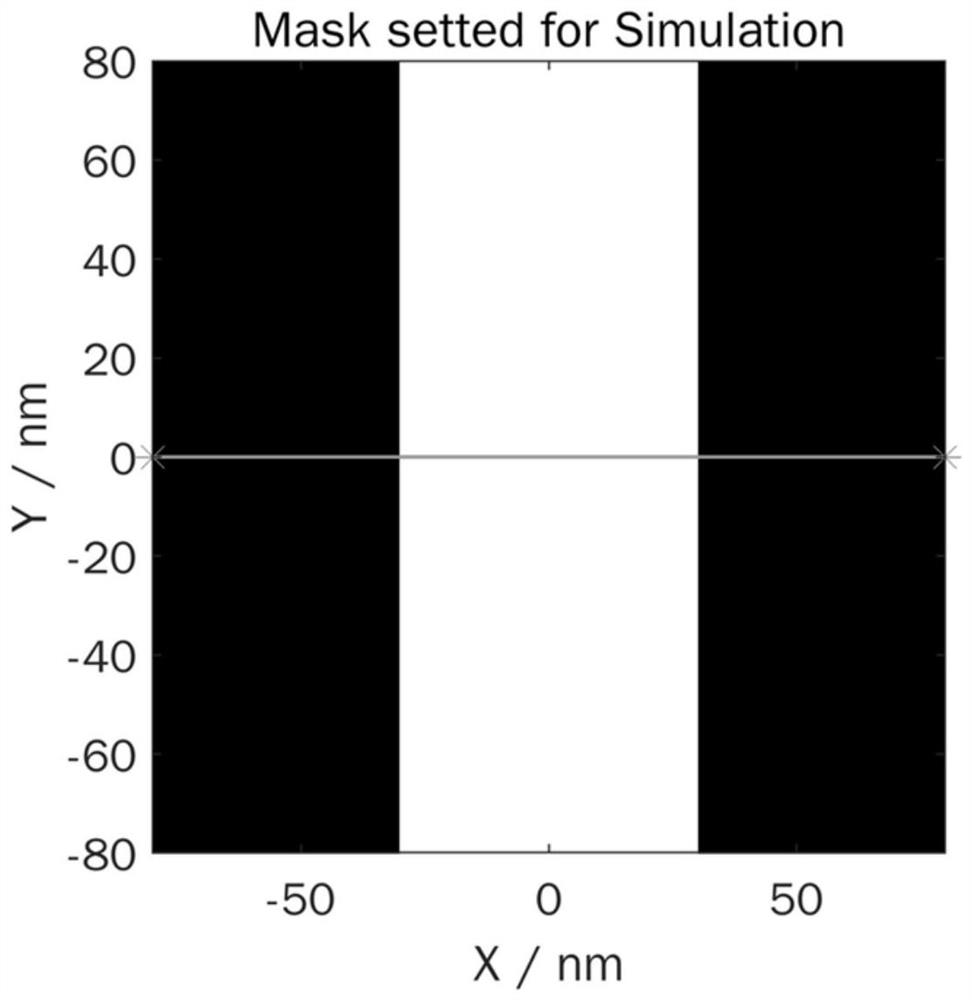

[0062] The illumination modes of the reference lithography machine and the lithography machine to be matched are described in a parameterized manner:

[0063]

[0065]

[0068]

[0071]

[0078]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A lithography machine matching method based on BFGS quasi-Newton-interior point algorithm. In this method, the key dimension of the aerial image is used as a parameter to describe the imaging performance of the lithography machine, and the parameterized description of the illumination light source of the lithography machine and the numerical aperture of the projection objective lens are optimized by the BFGS quasi-Newton-interior point algorithm, so as to achieve high-efficiency matching of the lithography machine. The invention uses the obstacle function to add constraints to the optimization problem, effectively utilizes the iterative information, improves the matching method of the non-free illumination system lithography machine, and improves the matching accuracy and efficiency of the existing method. Suitable for matching between immersion lithography machines with non-free illumination systems.

Description

Lithography machine matching method based on BFGS quasi-Newton-interior point algorithm technical field The present invention relates to lithography machine, particularly a kind of lithography machine matching method based on BFGS quasi-Newton-interior point algorithm. Background technique [0002] The lithography process is the core process of integrated circuit manufacturing. To reduce economic and time costs, photolithography processes are usually Refer to the research and development on the lithography machine. The new lithography process needs to be applied to the production line when the chip is mass-produced. Usually a production line has many The models and suppliers of lithography machines may be different, and the performance of different models of lithography machines generally varies. which is The same model of lithography machine may also cause lithography including imaging quality due to minor differences in its hardware specifications There is a big ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G03F7/20G03F1/36G03F1/00

CPCG03F7/705G03F7/70508G03F1/36G03F1/00

Inventor 陈俞光李思坤唐明胡少博王向朝

Owner SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com