Anti-dew ventilation method and facilities for main factory building of cold rolling factory

A ventilation method and anti-condensation technology, applied in space heating and ventilation, heating and ventilation control systems, heating and ventilation safety systems, etc., can solve energy medium-capacity, large steam volume, energy medium capacitance, Problems such as large steam volume and high investment cost at one time, achieve the effect of low energy consumption, small maintenance and repair workload, and simple pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

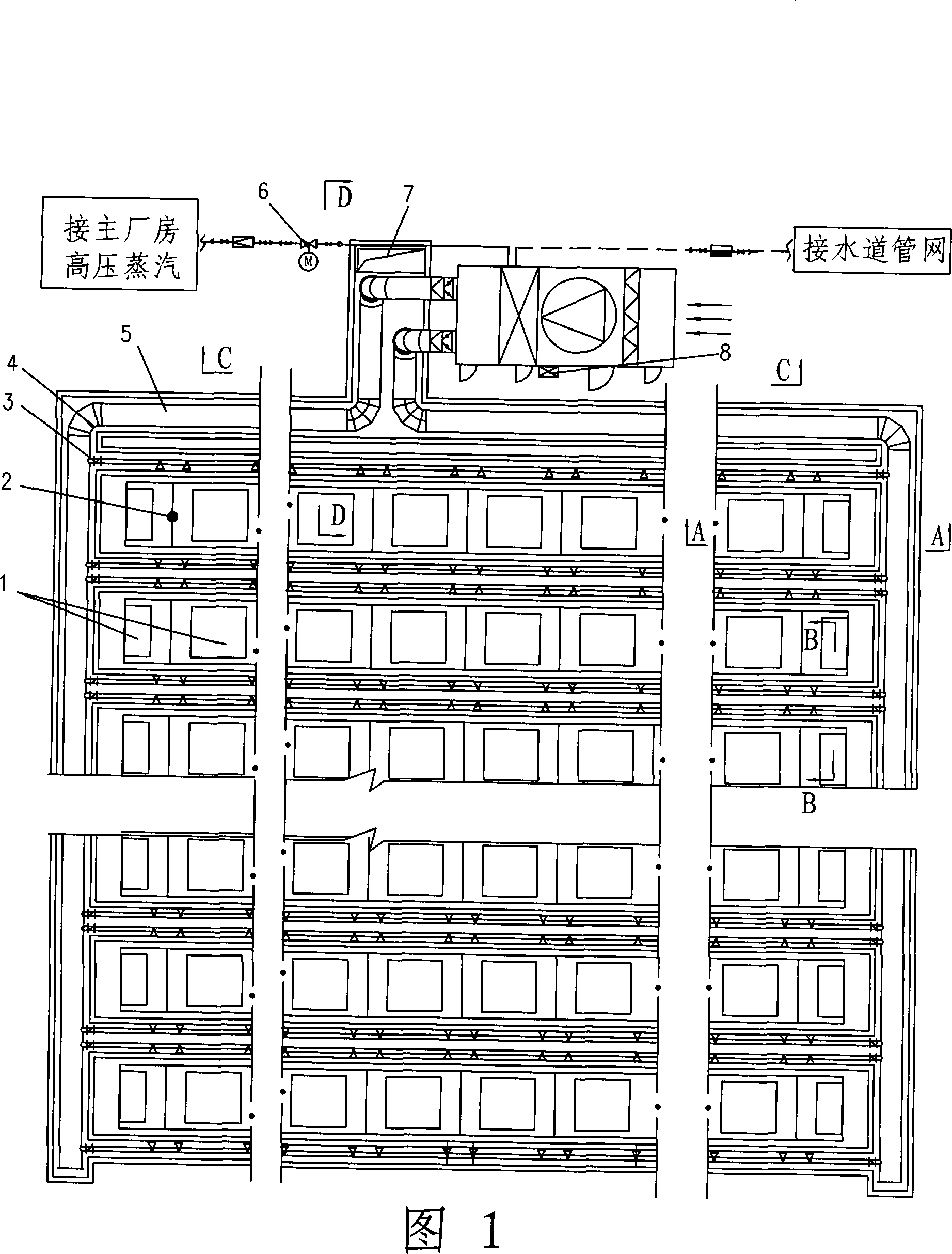

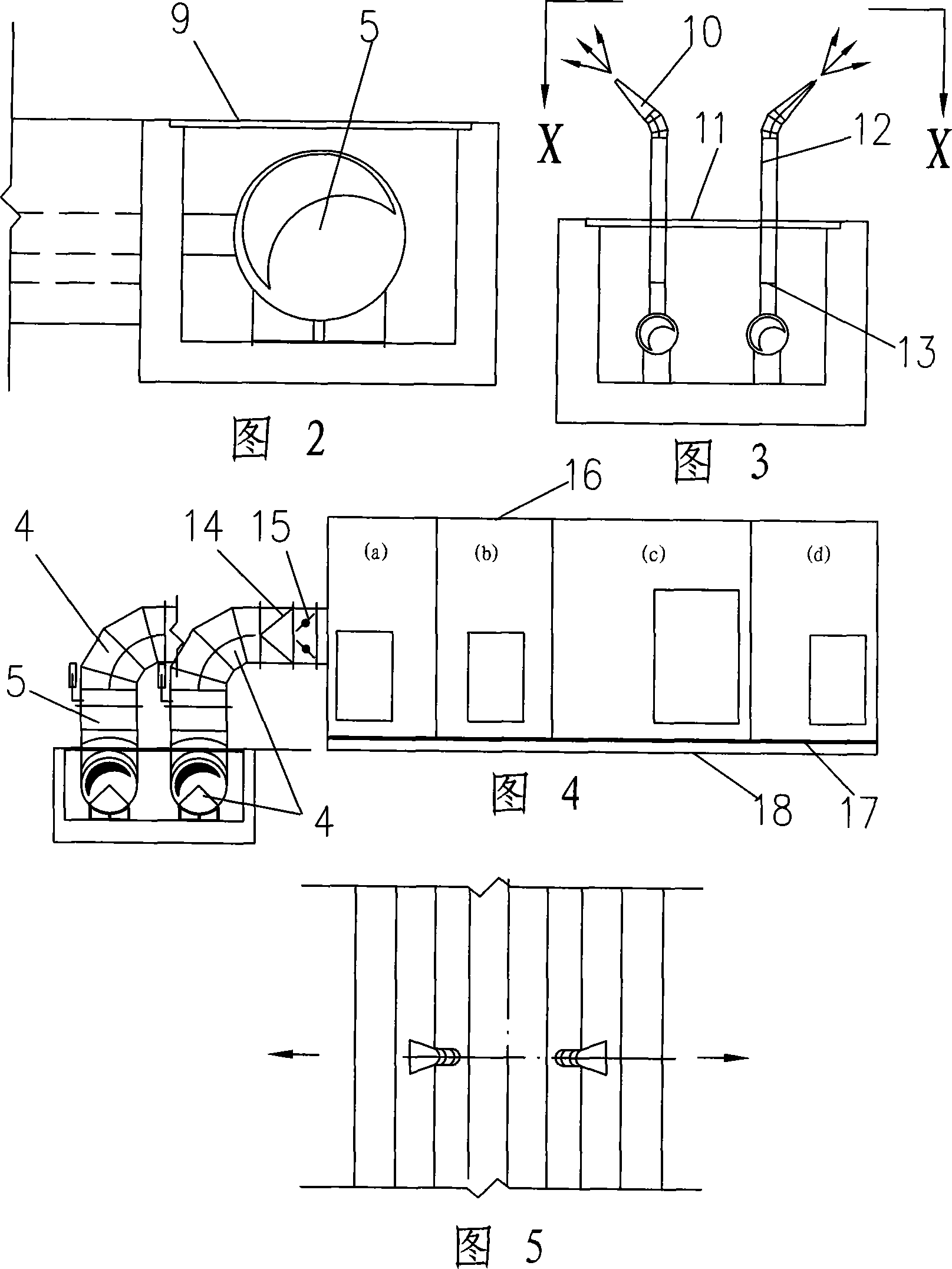

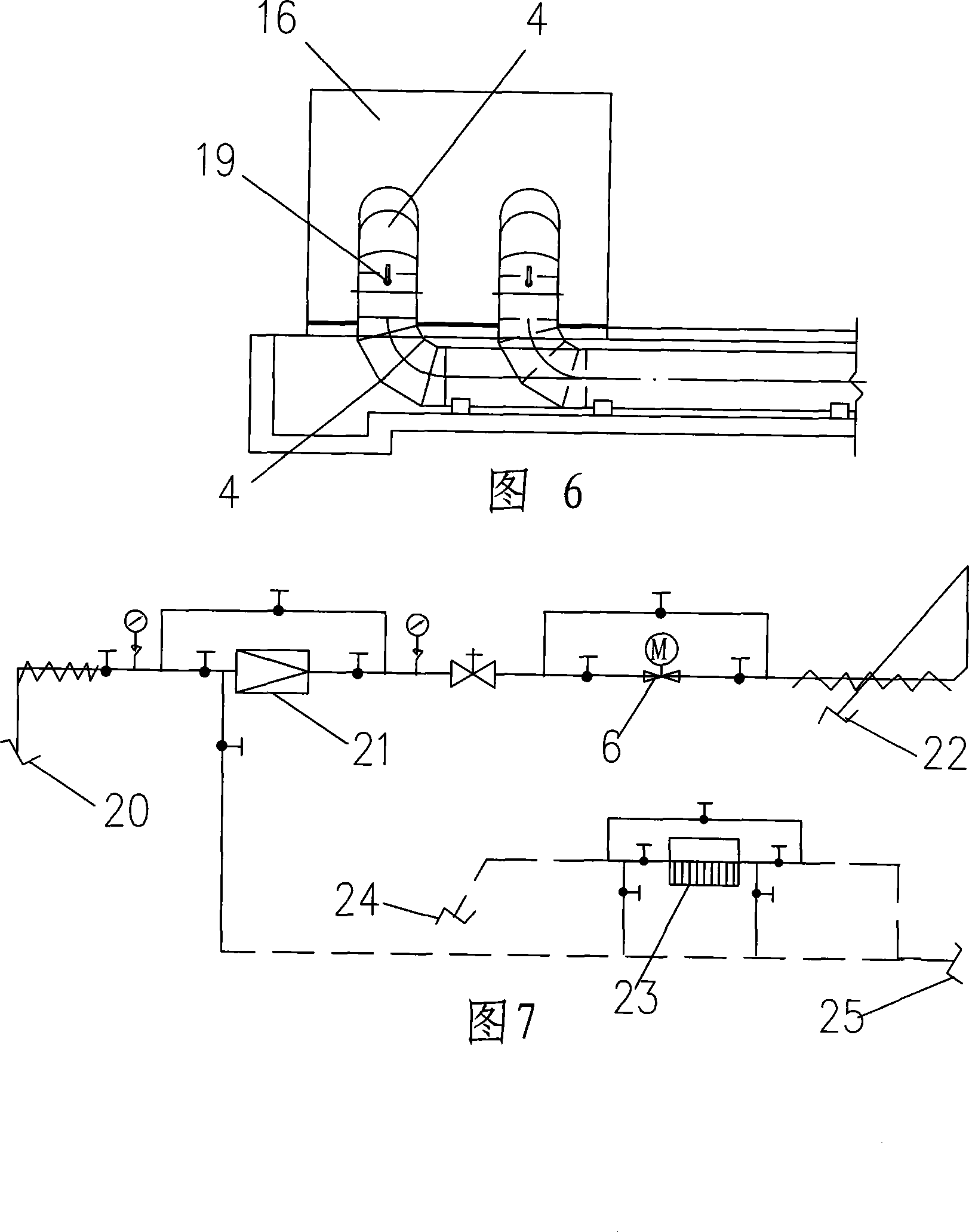

[0032] The anti-condensation ventilation method for the main building of a cold rolling mill provided by the present invention includes sending hot air and monitoring the dew point in the steel coil stacking area, and specifically adopts the following steps:

[0033] Dew point monitoring: Set up a dew point monitoring system in the steel coil stacking area, which sends a signal to the ventilation system in time according to the temperature data and alarm in the detection area fed back by one of the test coils set in each coil area, and the ventilation system sends hot air in time. Adjust the ambient air temperature and humidity so that the steel coil does not condense.

[0034] Hot air supply: According to the divided steel coil stacking area and height, a centralized hot air supply pipe network is laid on the surrounding floor of the steel coil, and a blower port is set on the pipe to blow high-speed hot air, forming a hot air curtain in the steel coil stacking area in a surro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com