Battery pack

A technology for battery packs and batteries, applied in secondary batteries, battery pack parts, secondary battery manufacturing, etc., can solve the problems of reduced manufacturing efficiency, long time, increased manufacturing costs, etc., and achieve the effect of eliminating poor contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described based on the drawings. However, the examples shown below illustrate battery packs for embodying specific technical ideas of the present invention, and the battery packs of the present invention are not limited to the following.

[0029] Furthermore, in this specification, in order to make it easy to understand the scope of patent claims, the numbers corresponding to the parts shown in an Example are attached|subjected to the parts shown in "patent claims" and "summary of the invention." However, the components shown in the patent claims are by no means limited to the components of the embodiment.

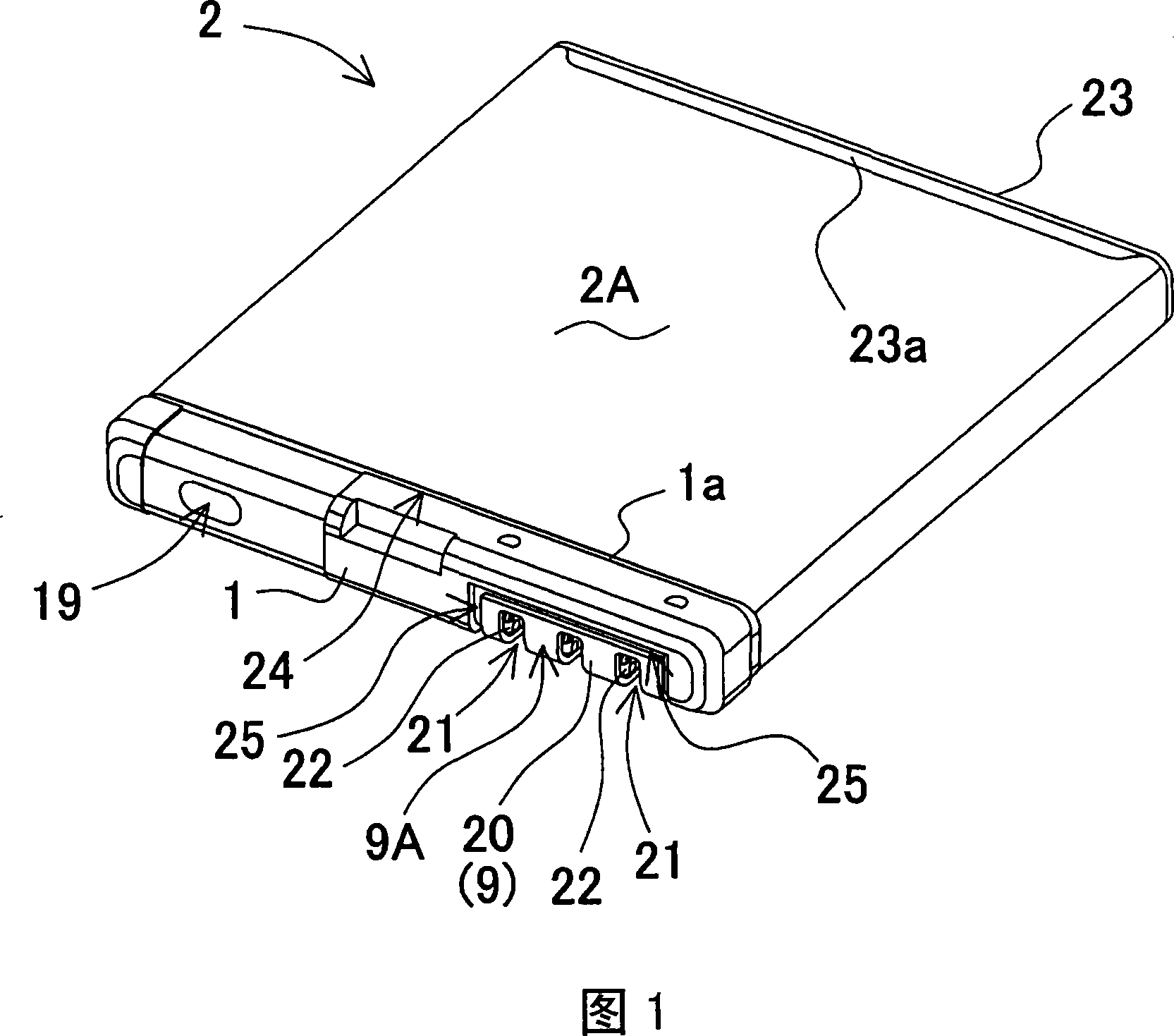

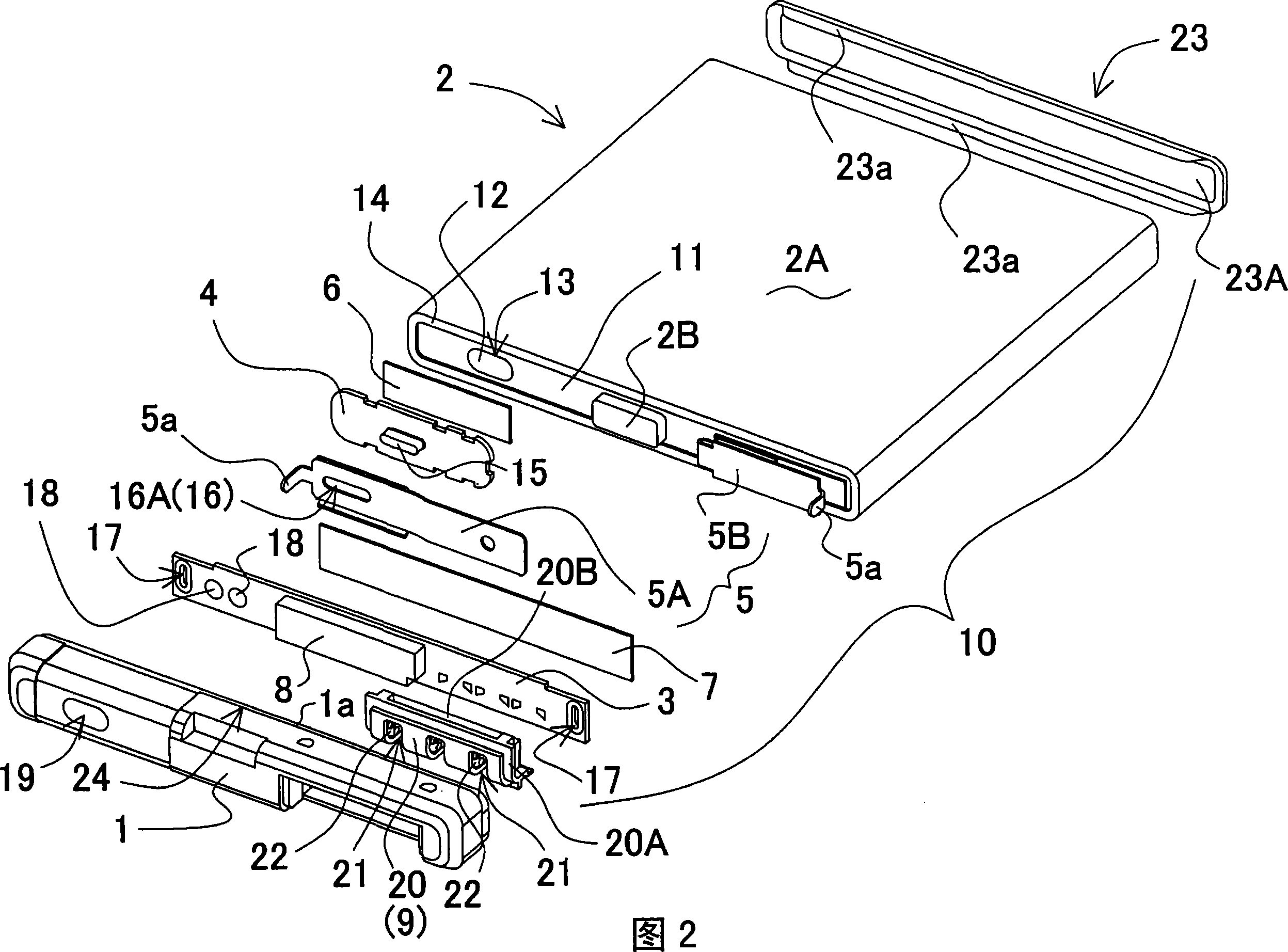

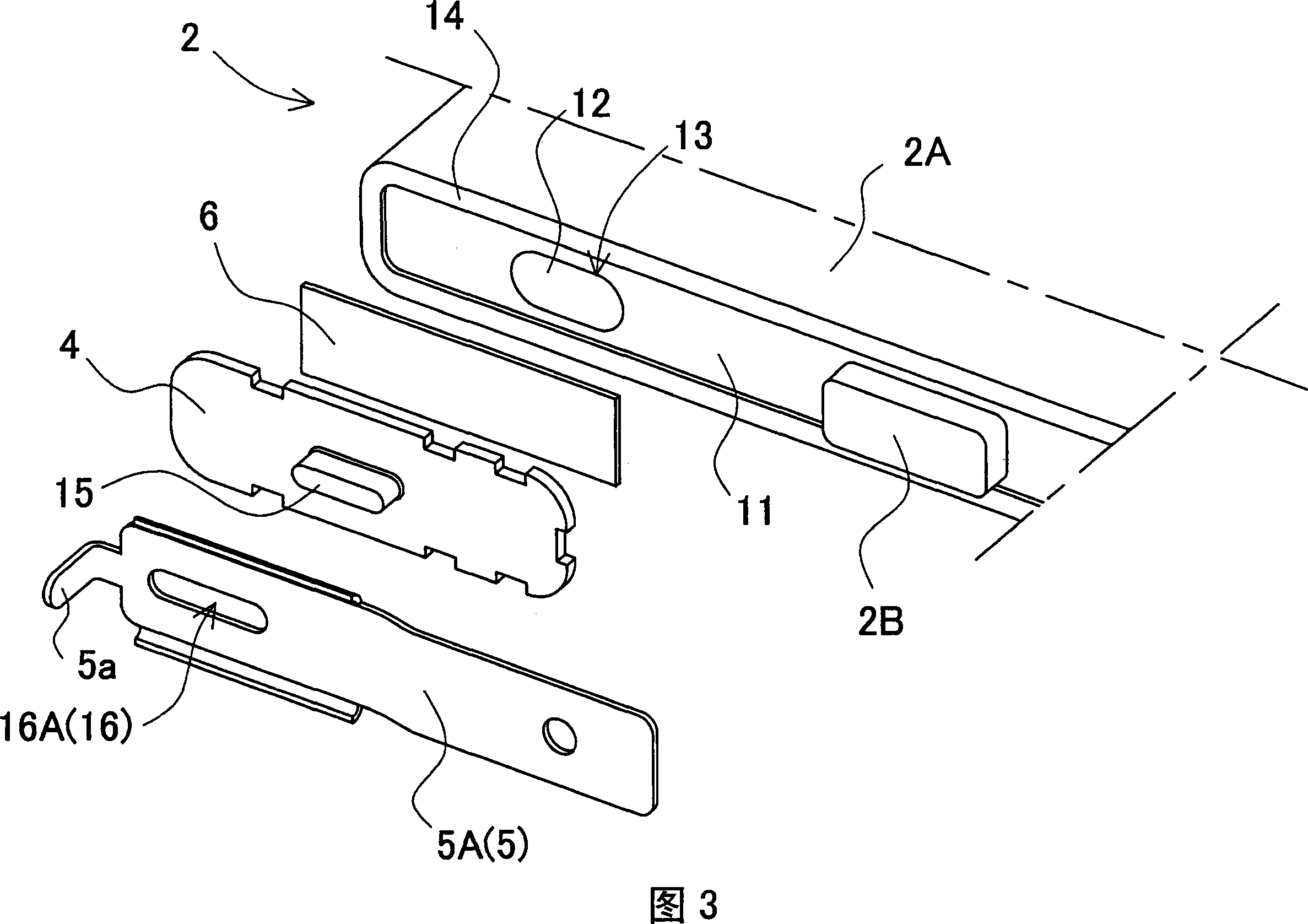

[0030] The assembled battery shown in FIGS. 1 to 4 is manufactured by inserting a battery core pack 10 into a resin molded part 1 . Fig. 2 is an exploded perspective view of the battery pack. This figure shows a state in which the resin molded part 1, the circuit board 3, the connector 9, the lead plate 5, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com