Epoxy asphalt automatic spraying device for steel deck

A technology of epoxy asphalt and steel bridge deck, which is applied in the field of road construction equipment and road construction. It can solve the problems of heavy spraying protective baffles, heavy environmental pollution, and easy heatstroke of workers, so as to prevent environmental pollution and damage to workers. health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

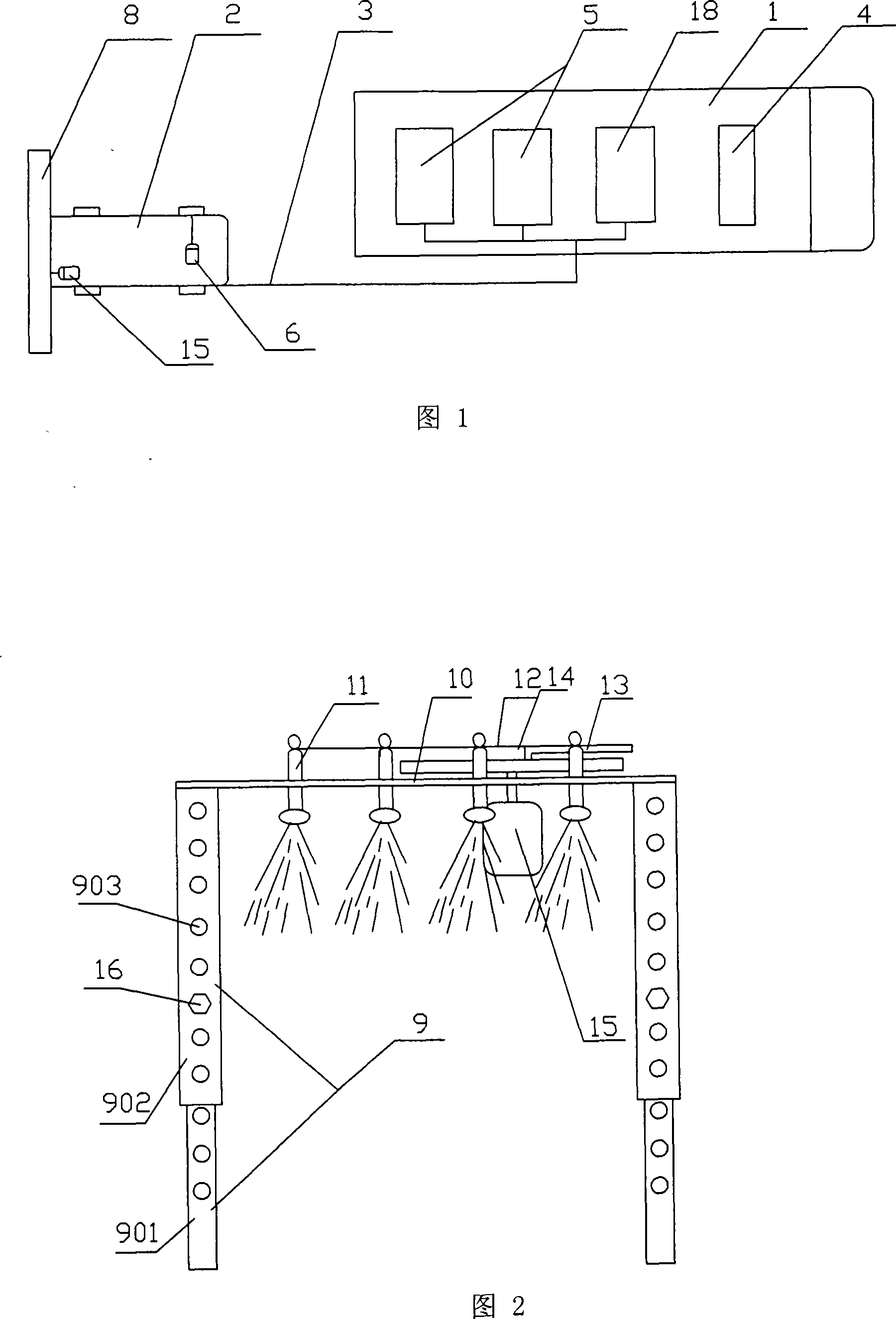

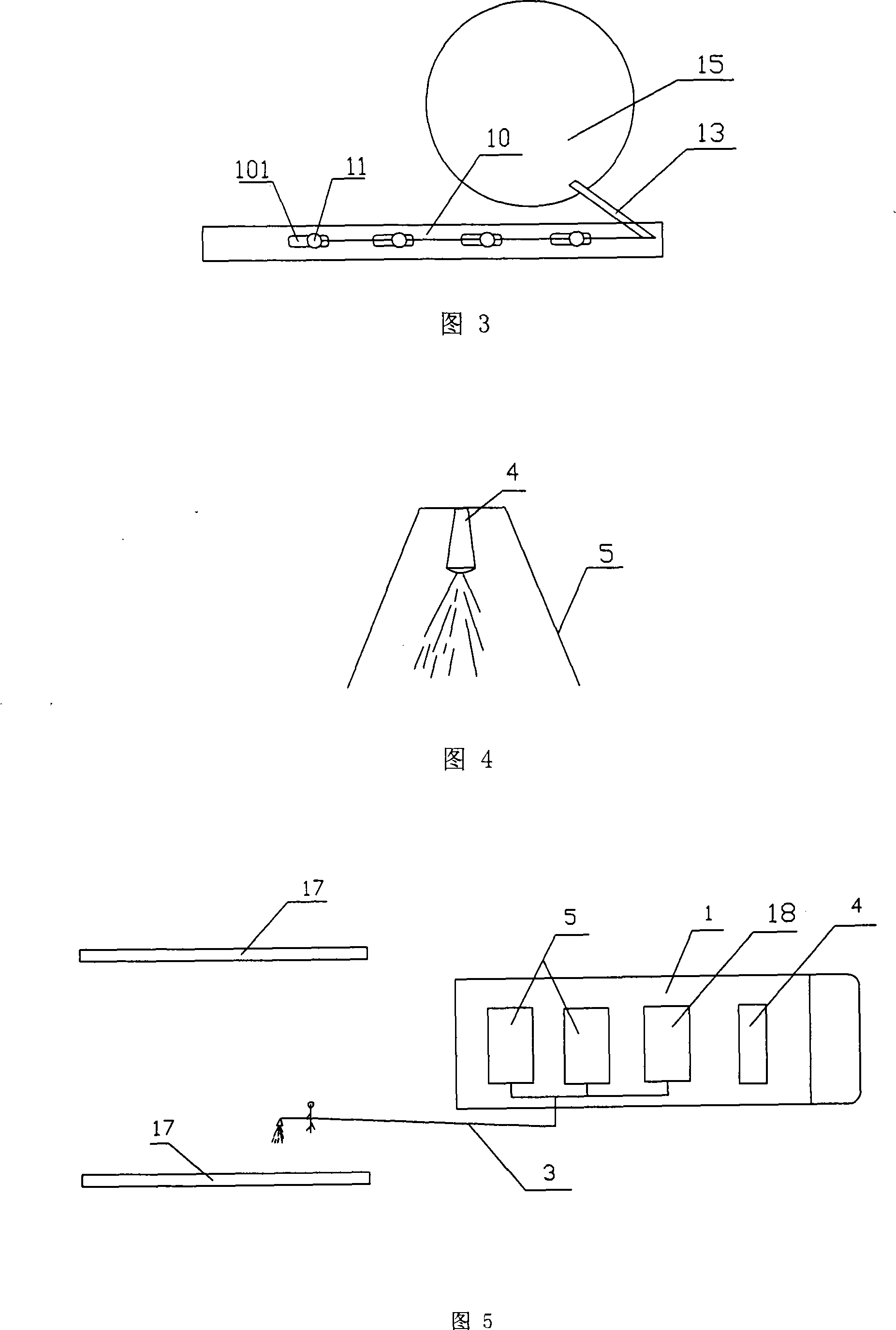

[0023] Shown in Fig. 1, 2 and 3, steel bridge deck epoxy asphalt automatic spreading device of the present invention is made up of asphalt loading flat car 1 and spreading car 2, is connected by asphalt conveying pipeline 3 and electric wire between them, in loading flat car 1 A generator 4, an air compressor motor 18 and epoxy asphalt storage and measuring equipment 5 are installed on the top, a driving motor 6 is provided on the distribution vehicle 2, a windshield 7 is covered on the distribution vehicle 2, and at the rear of the distribution vehicle 2 Also establish spreading mechanism 8, described spreading mechanism is made up of support 9 adjustable up and down, crossbeam 10 and asphalt nozzle 11, and crossbeam 10 is fixed on the support 9, and asphalt nozzle 11 is installed on the crossbeam 10, and described asphalt nozzle 11 is connected with the crank linkage mechanism, and the lower part of the asphalt nozzle 11 is connected with the crank linkage mechanism through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com