Structure of truss-string cantilever as well as uses and construction method thereof

A cantilever beam and string cable technology, which is applied in building components, building structures, roofs, etc. to reduce impact damage and achieve self-protection effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

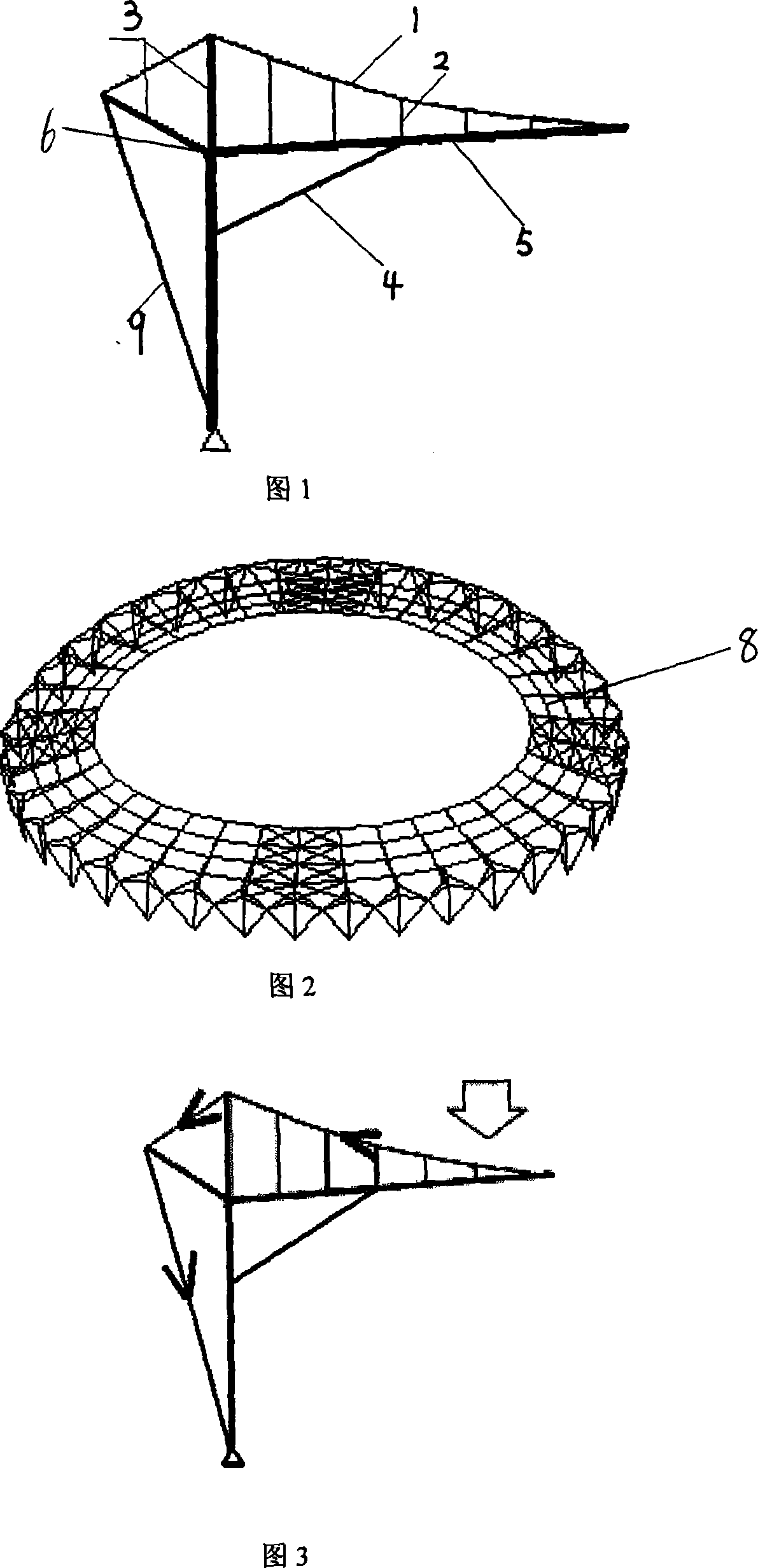

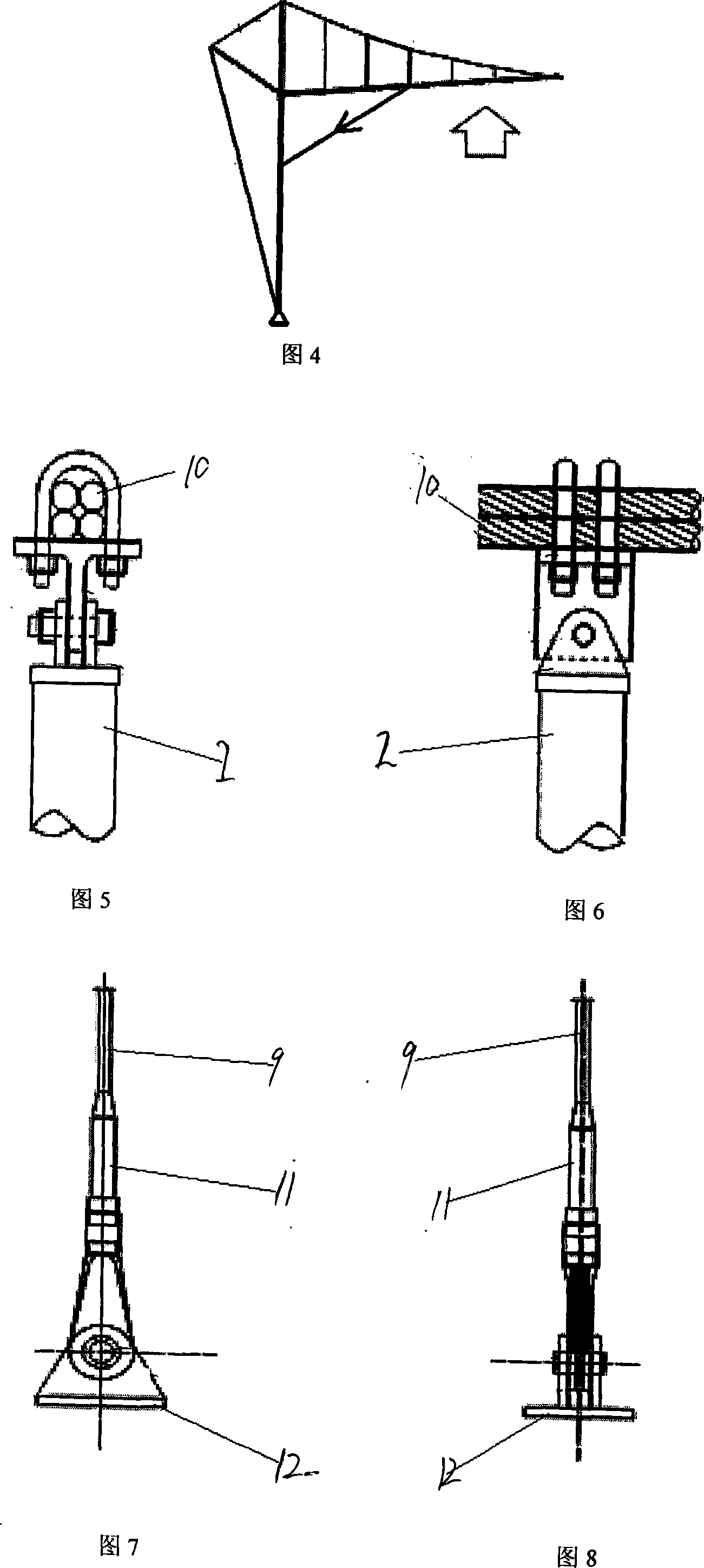

[0025] As shown in Figure 1, a string tension cantilever beam structure provided by the present embodiment includes a cantilever beam 5 and a compression bar 3, an upper string 1 and a vertical bar 2 are arranged on the cantilever beam 5, and a cantilever beam 5 bottom is provided with Stabilizing cable 4 constitutes a single string cantilever beam structure 7 thus. The end of the cantilever beam 5 is provided with a bearing 6, and the end of the cantilever beam 5 and the bearing 6 are connected by a hinged bearing.

Embodiment 2

[0027] The string tension cantilever beam structure provided in this embodiment is a prestressed structure, which needs to rely on the prestress of the upper string 1 and the stabilizing cable 4 to reach the final forming state. Therefore, as shown in Figure 2, combined with the specific characteristics of the structure, the single cantilever beams 7 can be arrayed along the ring direction and connected by ring beams 8 to form a canopy structure. The above string cantilever beam structure is applied to the canopy structure of the stadium. When being used to build a canopy structure composed of multiple stringed cantilever beams, the construction method of a stringed cantilever beam structure is to first install the cantilever beam 5, the vertical bar 2, the pressure bar 3 and the upper string cable 1 according to the The formed dimensions are made and installed in place; then the ring beams 8 are used to connect each string cantilever beam structure 7 together to form a whole;...

Embodiment 3

[0032] Fig. 5 and Fig. 6 are diagrams of connection nodes between the upper chord cable 1 and the vertical bar 2 or pressure bar 3, as shown in Fig. To make the tensioning adjustment of the dragline multiple times, the present invention adopts double-layer PE anti-corrosion steel wire 10. The joint adopts the combination of hot cast anchor and cold cast anchor. At the same time, a cable length adjusting device 11 is set in the cable to adjust the tension value of the cable. The cable length adjusting device 11 is a steel sleeve for adjusting the cable length. Its main node forms are shown in Figure 5, Figure 6, Figure 7, and Figure 8. Fig. 7 and Fig. 8 are connection node diagrams of the rear cable 9 and the ground anchor; when the stabilizing cable 4 is connected with the cantilever beam 5 or column, the connector 12 is embedded in the beam or column first, and then the node connection form is basically the same as that in Fig. 8 .

[0033] The structure of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com