Liquid crystal display module and support device thereof

A technology of liquid crystal display modules and supporting devices, which is applied in the direction of nonlinear optics, instruments, optics, etc., and can solve the problems of optical diaphragm group falling off, unable to maintain between 0.15-0.2 mm, and affecting the picture effect of liquid crystal display devices, etc. To achieve the effect of preventing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

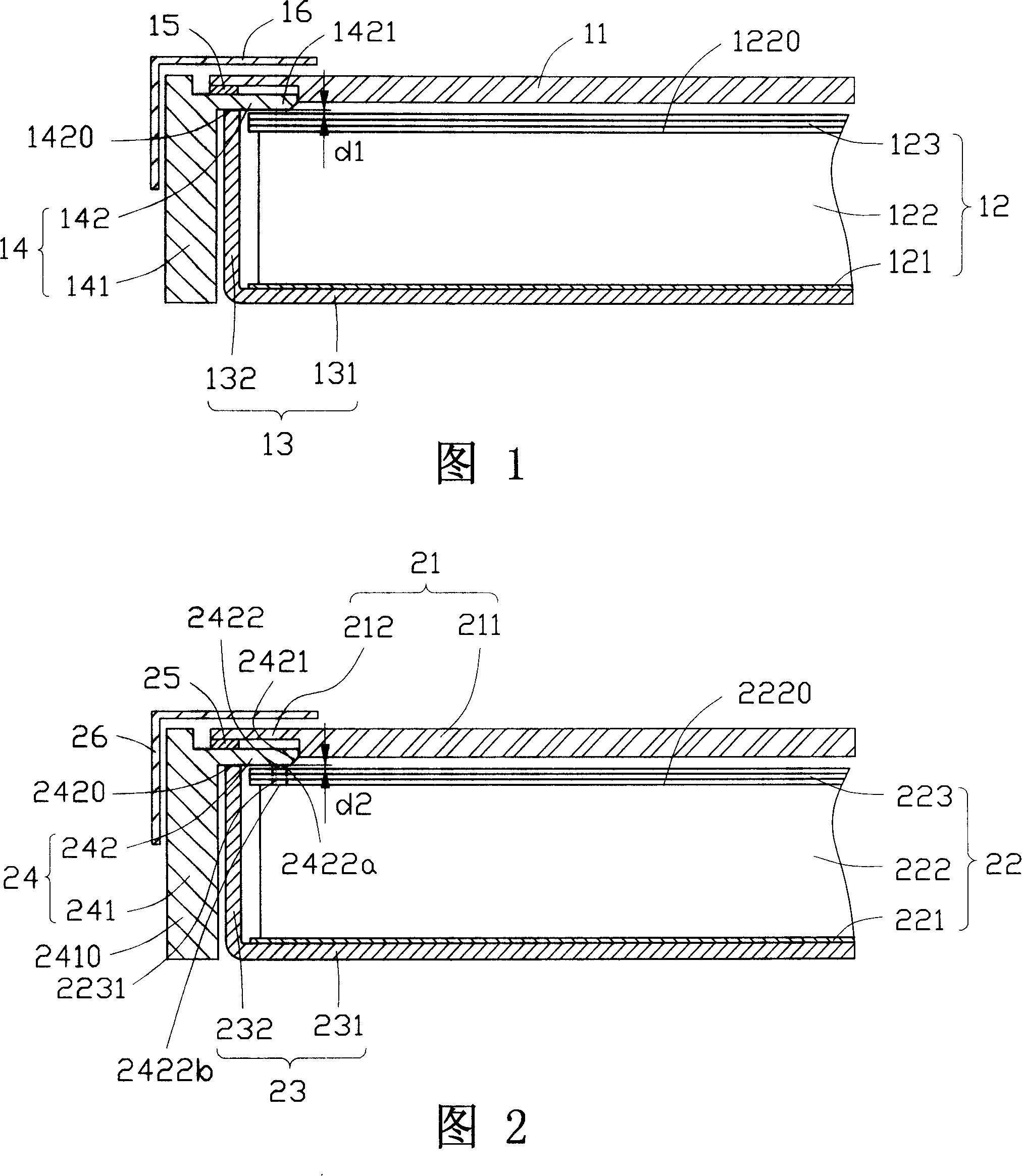

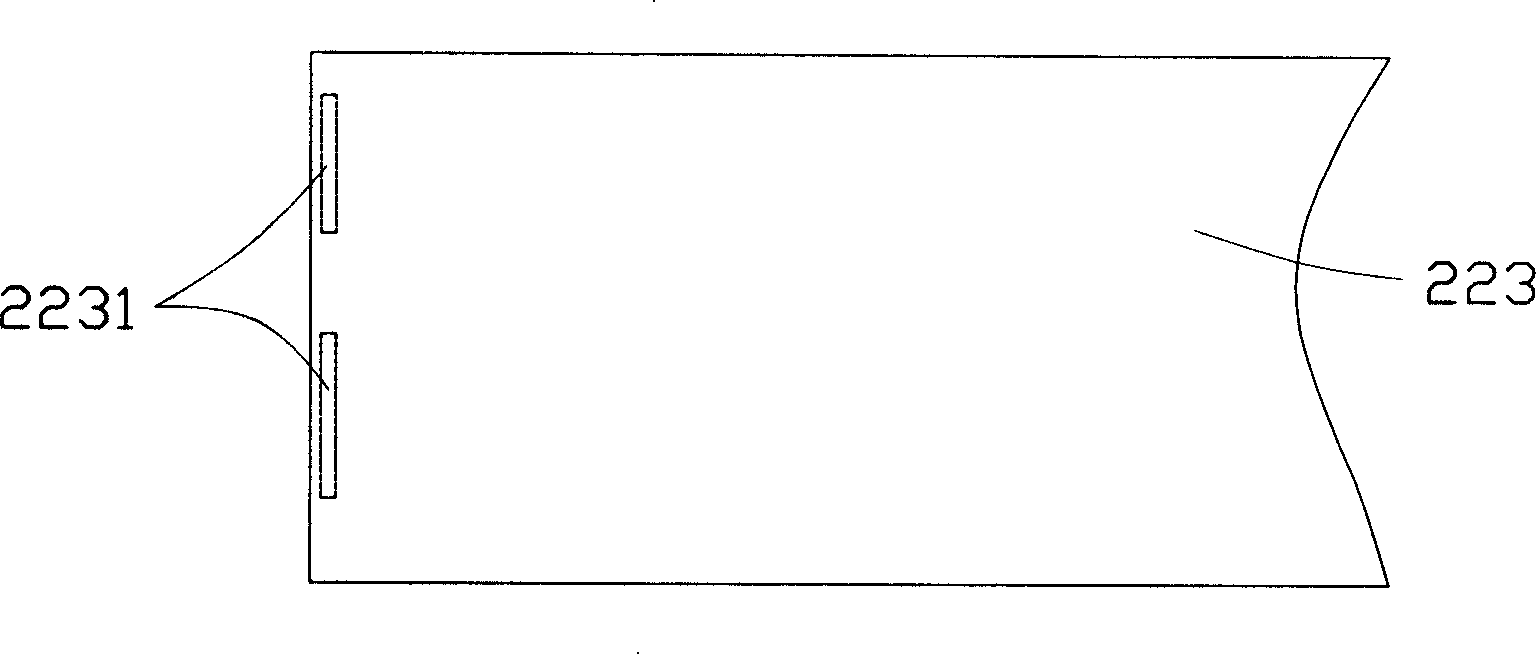

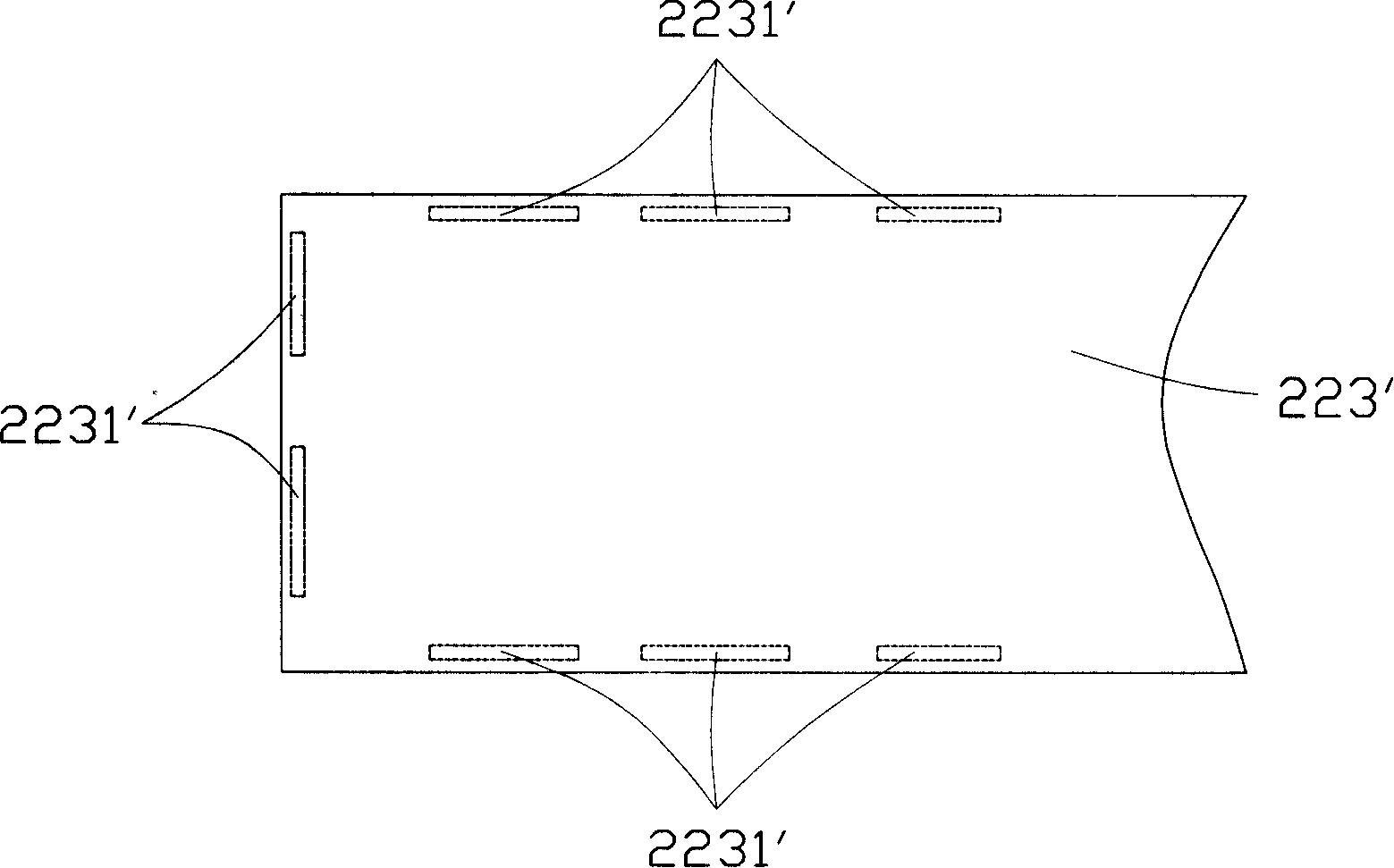

[0011] Please refer to Fig. 2, which is a liquid crystal display module according to a preferred embodiment of the present invention, which mainly includes a liquid crystal display panel 21 and a backlight module 22 arranged behind the liquid crystal display panel 21 to provide light to the liquid crystal display panel 21, And a supporting device for supporting and fixing the liquid crystal display panel 21 and the backlight module 22 . The supporting device further includes a back plate 23 , a plastic frame 24 and an annular glass plate 25 covering the plastic frame 24 , and the liquid crystal display panel is covered on the glass plate 25 . The supporting device and the liquid crystal display panel 21 are surrounded by a frame 26, and then installed in a casing of a liquid crystal display device.

[0012] The liquid crystal display panel 21 includes a screen portion 211 erected on the optical film set 223 and an extension portion 212 located around the screen portion 211 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com