Method for sterilizing preforms and installation for producing sterile bodies from these preforms

A disinfection method and preform technology, applied in disinfection, bottle filling, liquid bottling, etc., can solve problems such as uneven coverage of disinfectants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] [48] Hereinafter, similar or identical components are denoted by the same reference numerals.

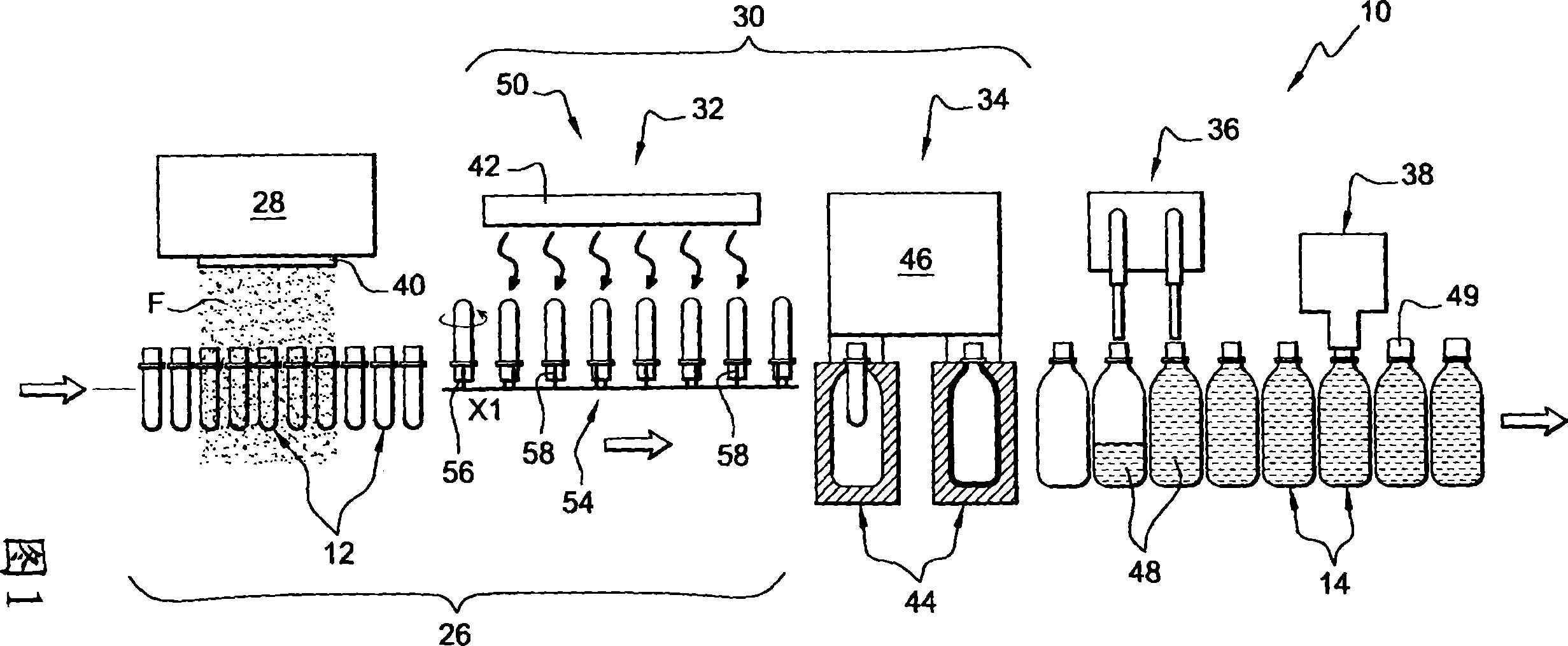

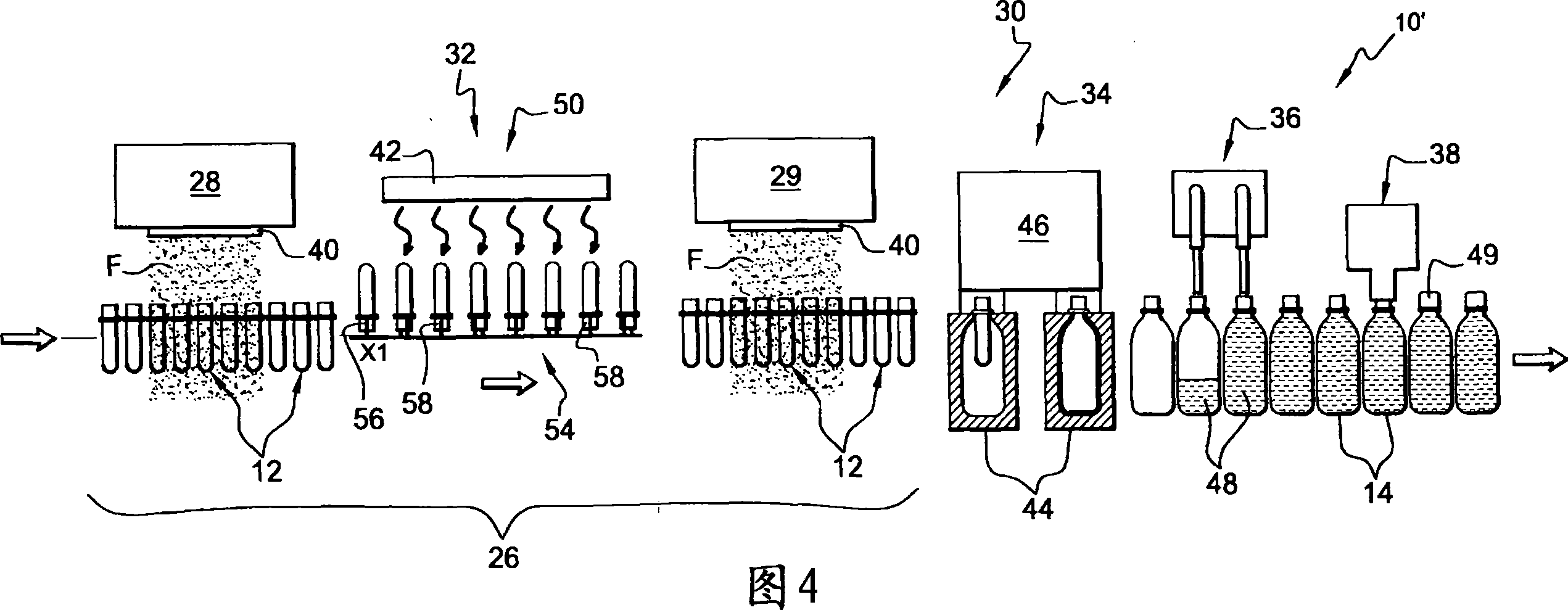

[0049] [49] FIG. 1 shows a plant 10 for the production of bottles 14, in particular aseptic or sterile bottles, advantageously obtained from plastic preforms 12 by blow molding.

[0050][50] Such a plant 10 is used, for example, for the manufacture of plastic bottles 14, such as polyethylene terephthalate (PET).

[0051] [51] Each preform 12 generally has the shape of a tube closed at one end and already having the final shape of the neck 16 of the bottle 14 at the other end.

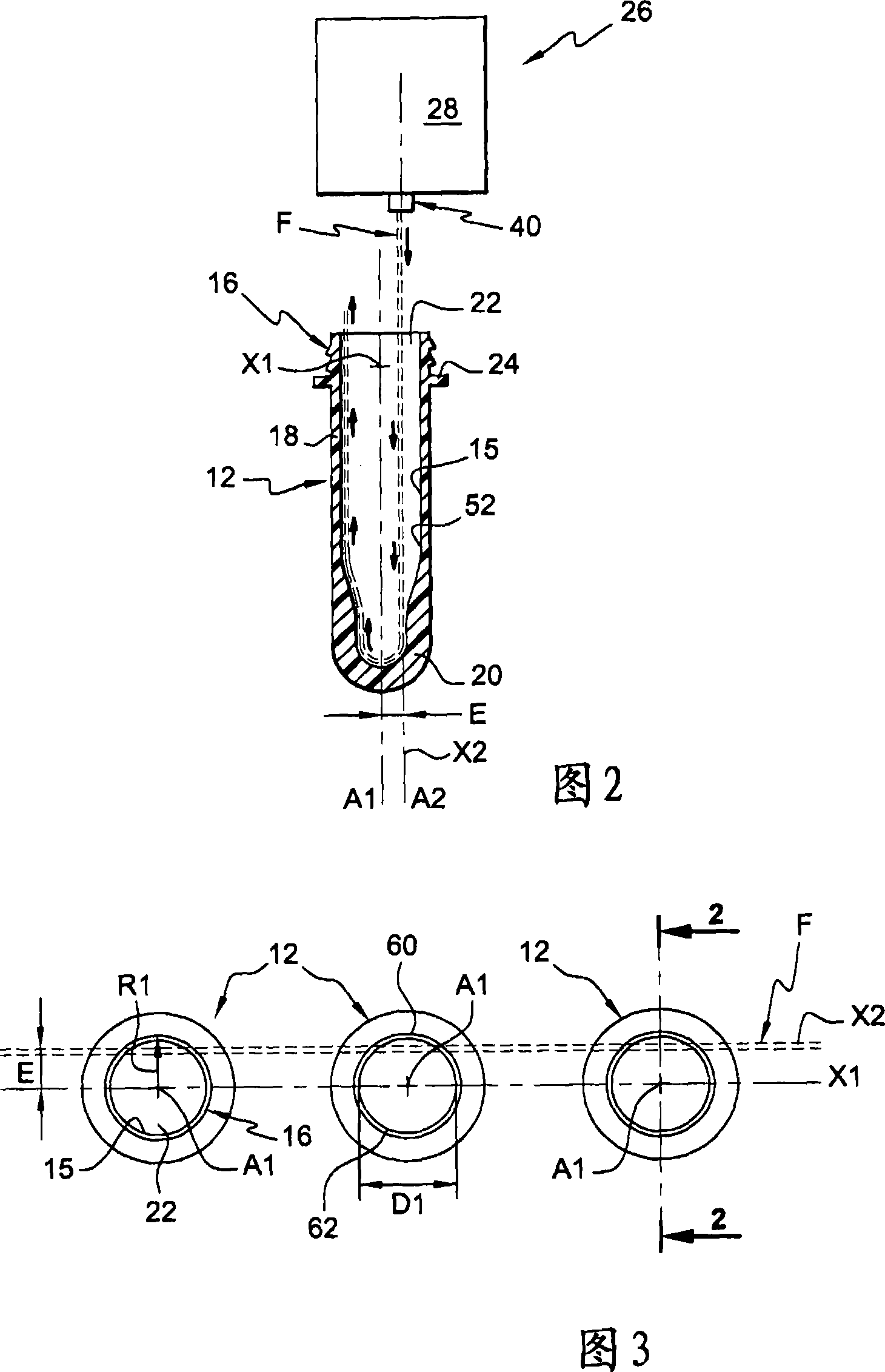

[0052] [52] As a non-limiting example, FIG. 2 shows a preform 12 whose cylindrical body 18 has an axis A1 extending perpendicularly and coincides with the axis of the neck 16 .

[0053] [53] The lower end 20 of the preform 12 is closed, whereas its upper end forms a neck 16 which delimits an inner opening 22 and is provided here with an outer radial flange 24 .

[0054] [54] The preform 12 is typic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com