Composite materials of aerogel and phase change material

A phase change material, aerogel technology, applied in mechanical equipment, pipeline protection, pipeline protection through thermal insulation, etc., can solve problems such as poor thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

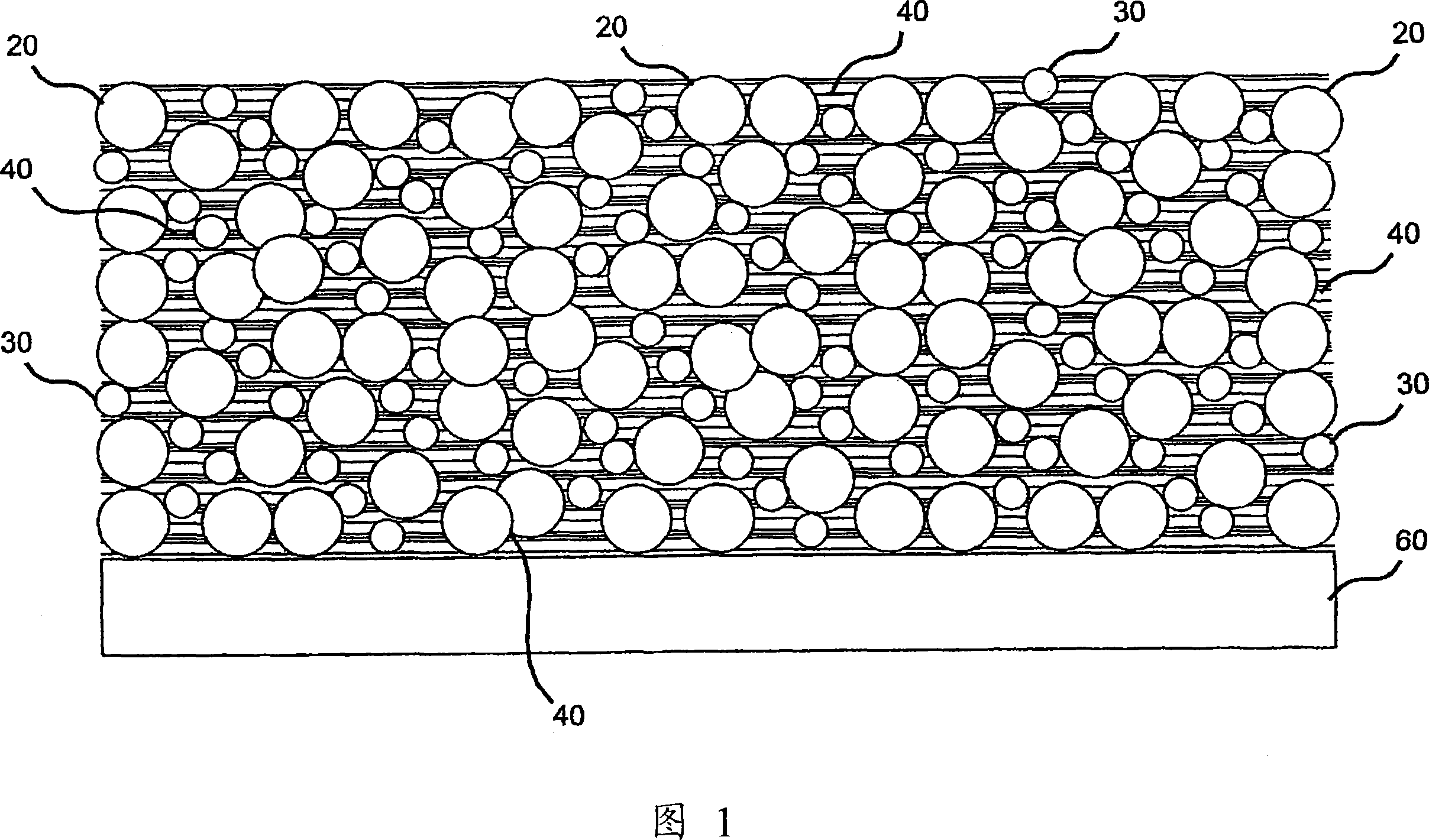

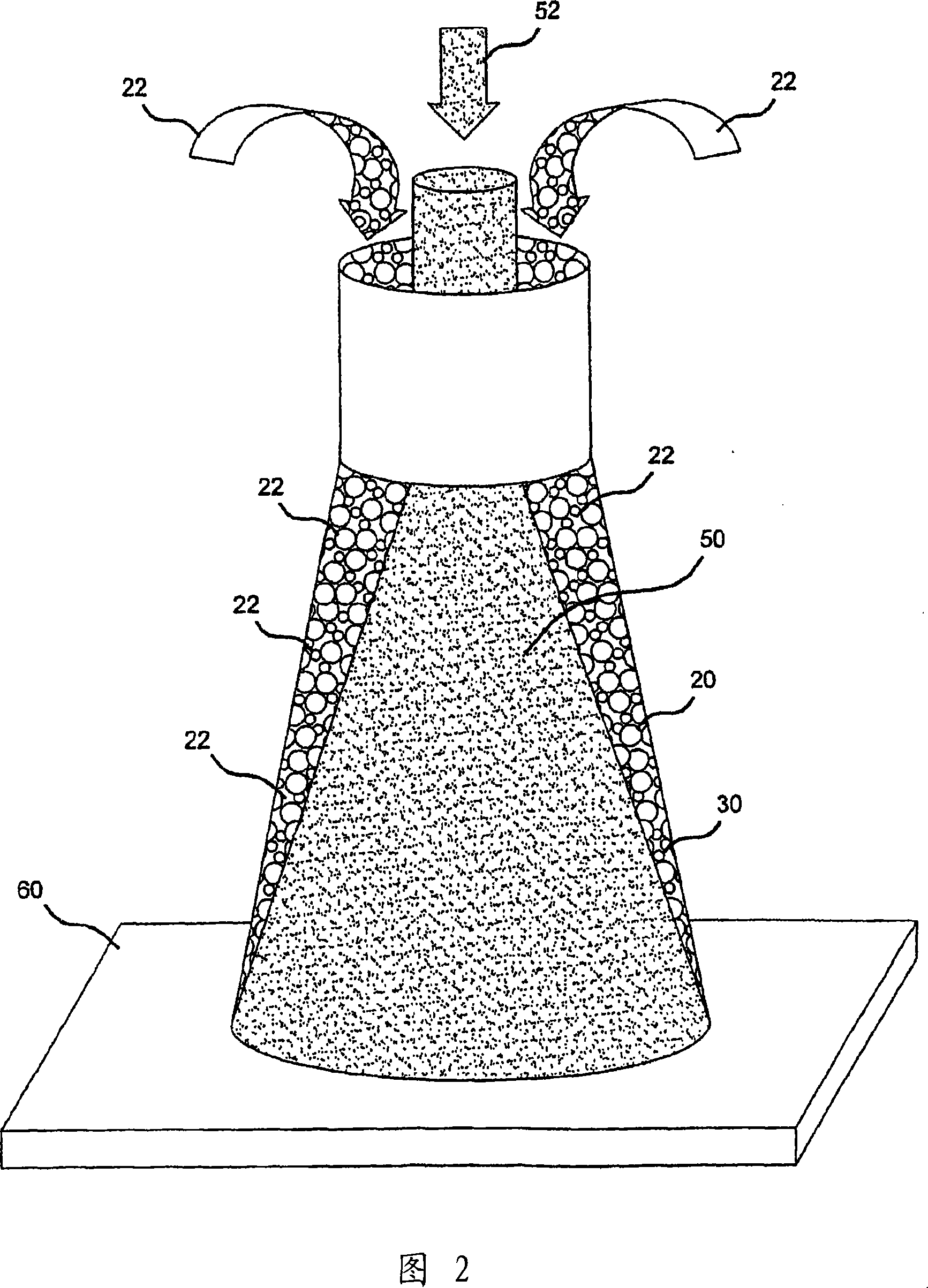

[0033] Deposition of the silicone matrix adhesive 40, airgel 20 and PCM 30 materials was achieved using the apparatus shown schematically in FIG. 2 for coating on substrates. A preferred method is the convergent spray process. Using the converging spray method, the airgel particles 20 are mixed with the liquid silicone precursor 50 at the time of deposition on the substrate 60 or just prior to deposition on the substrate 60 .

[0034] PCM beads may also be included, and they may be included in the silicone mixture 50, or they may be included with the airgel 20 or separately. Thus, two or more deposition fluids may be used. This deposition method minimizes breakage of the friable airgel particles and minimizes solvent uptake by the particles. Formation of the deposition fluid may be accomplished using any conventional spraying device. Preferred deposition rates are shown in Table 1 along with exemplary compositions of deposited materials.

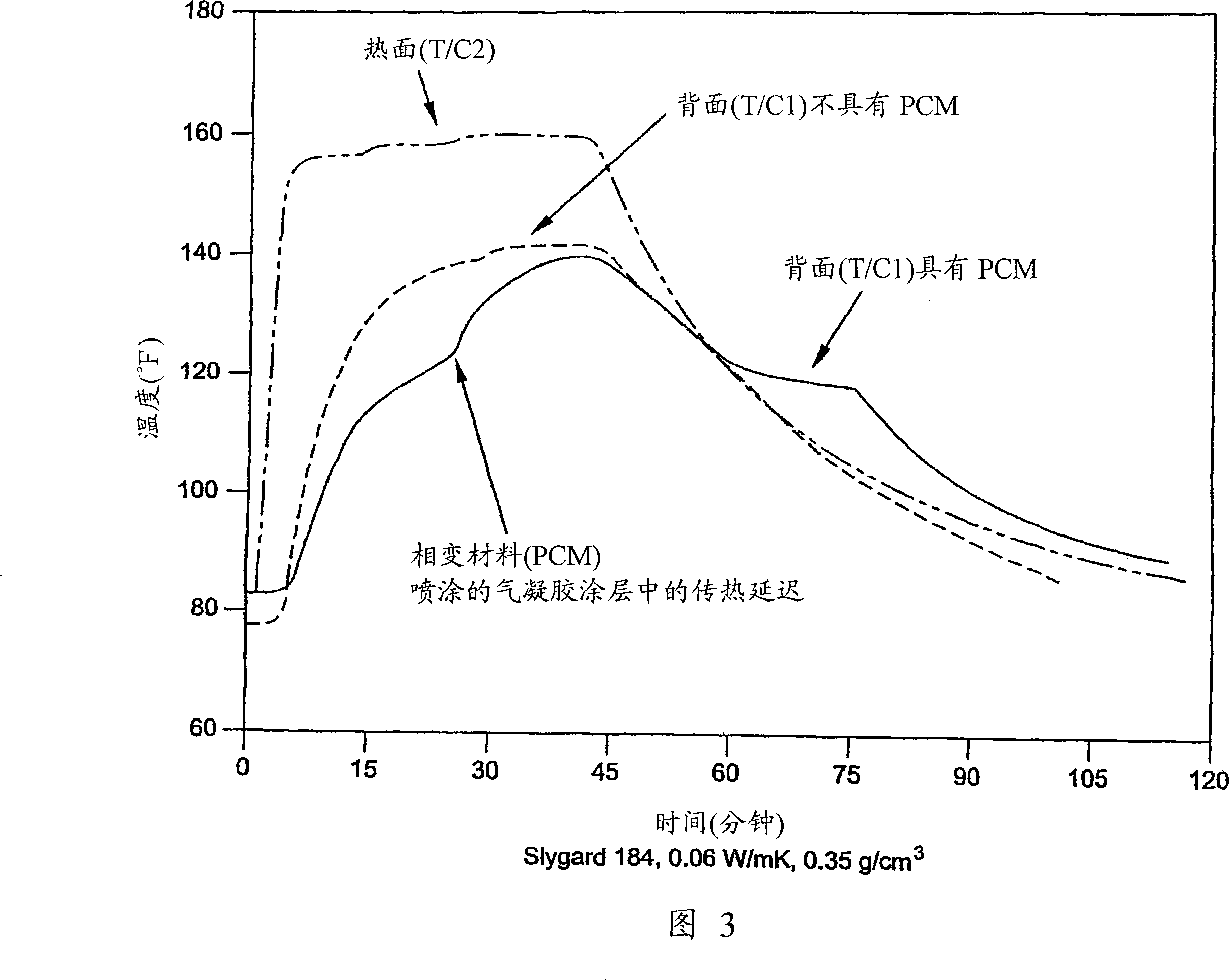

[0035] Table 1 also includes ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com