Textile machine that produces cross-wound bobbins

A technology of cross-winding bobbins and textile machines, which is applied in textile testing, textile and papermaking, and material inspection products, etc. It can solve the problems of inaccurate detection results, insufficient success of known devices, and dispersion, and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

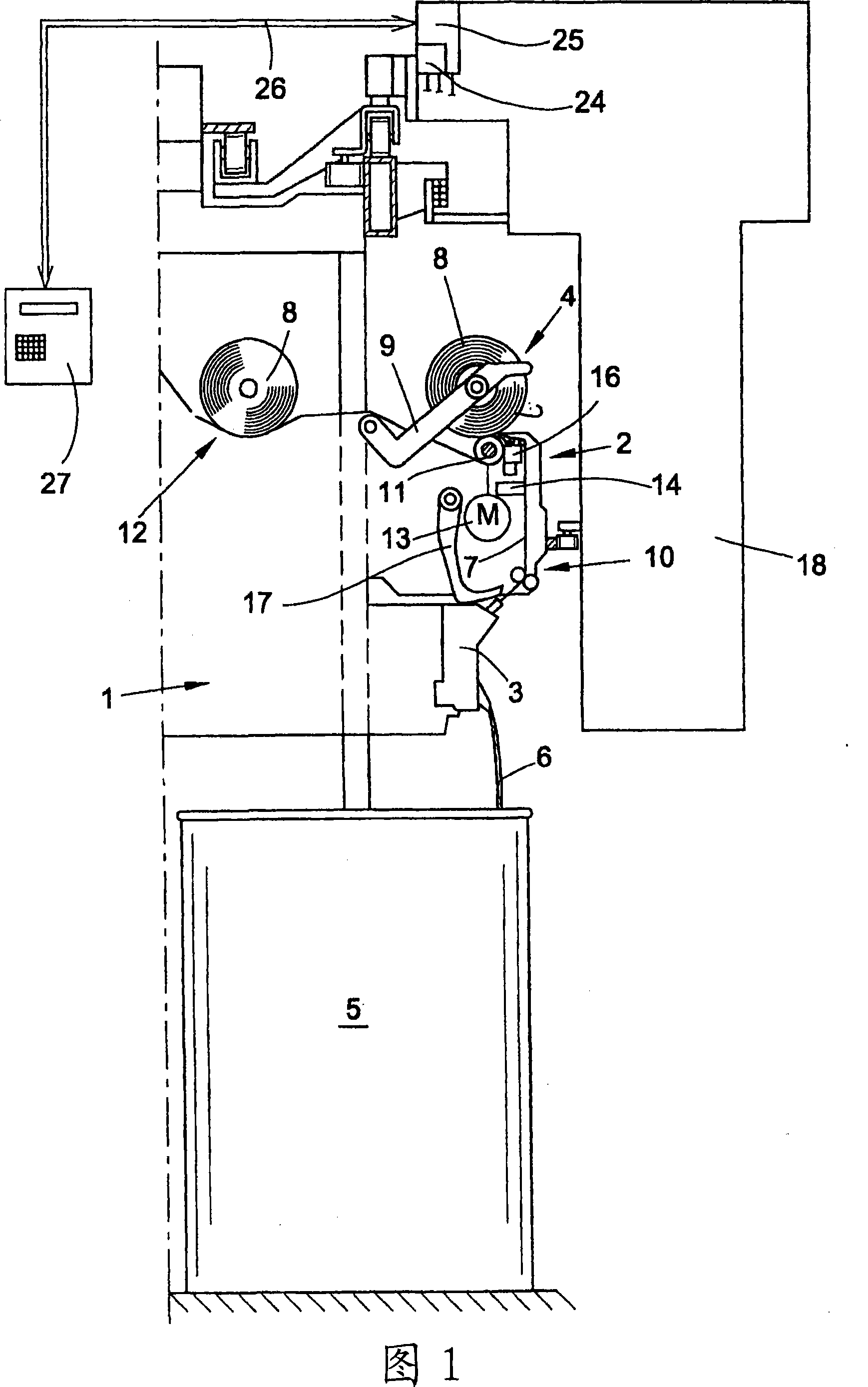

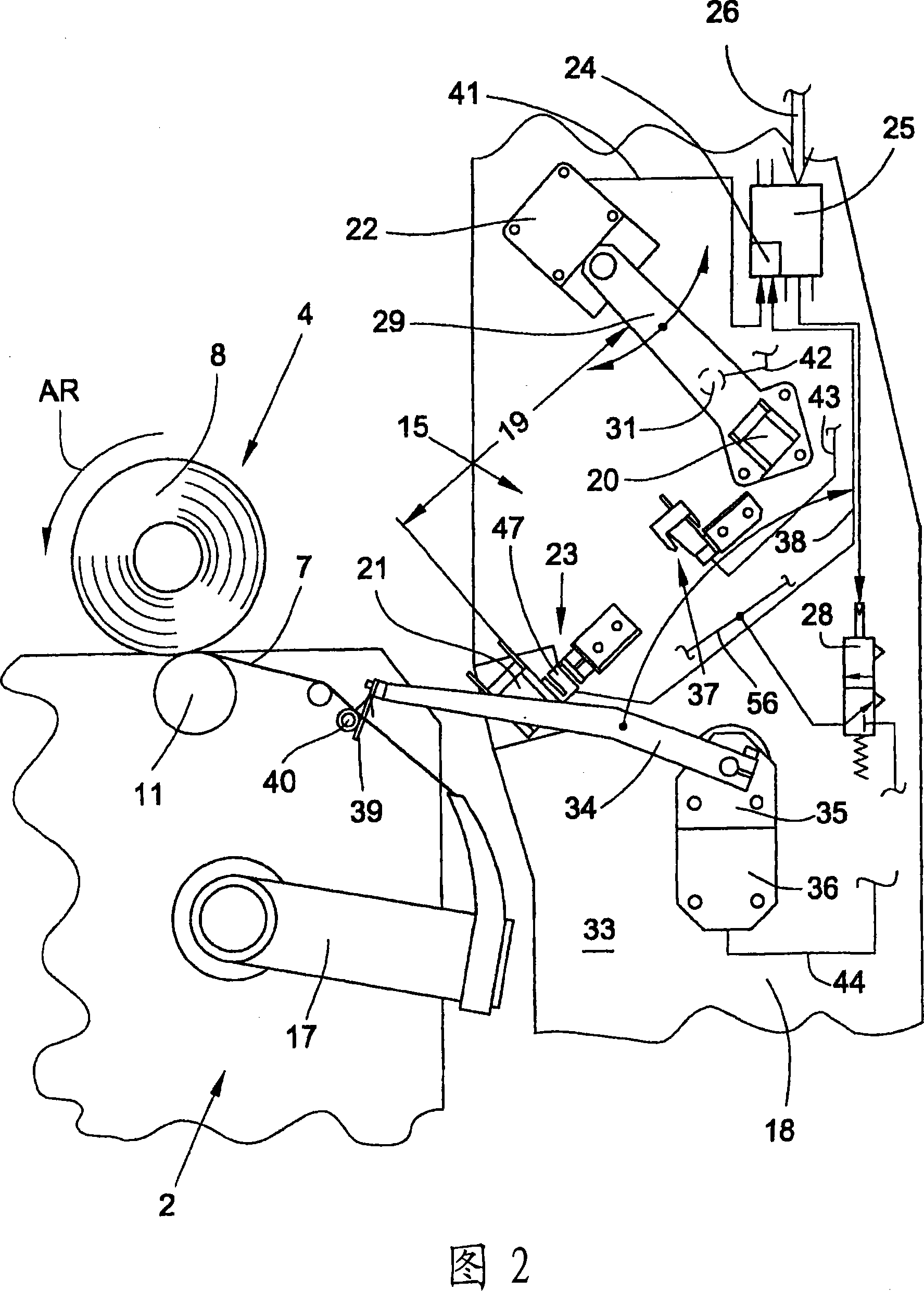

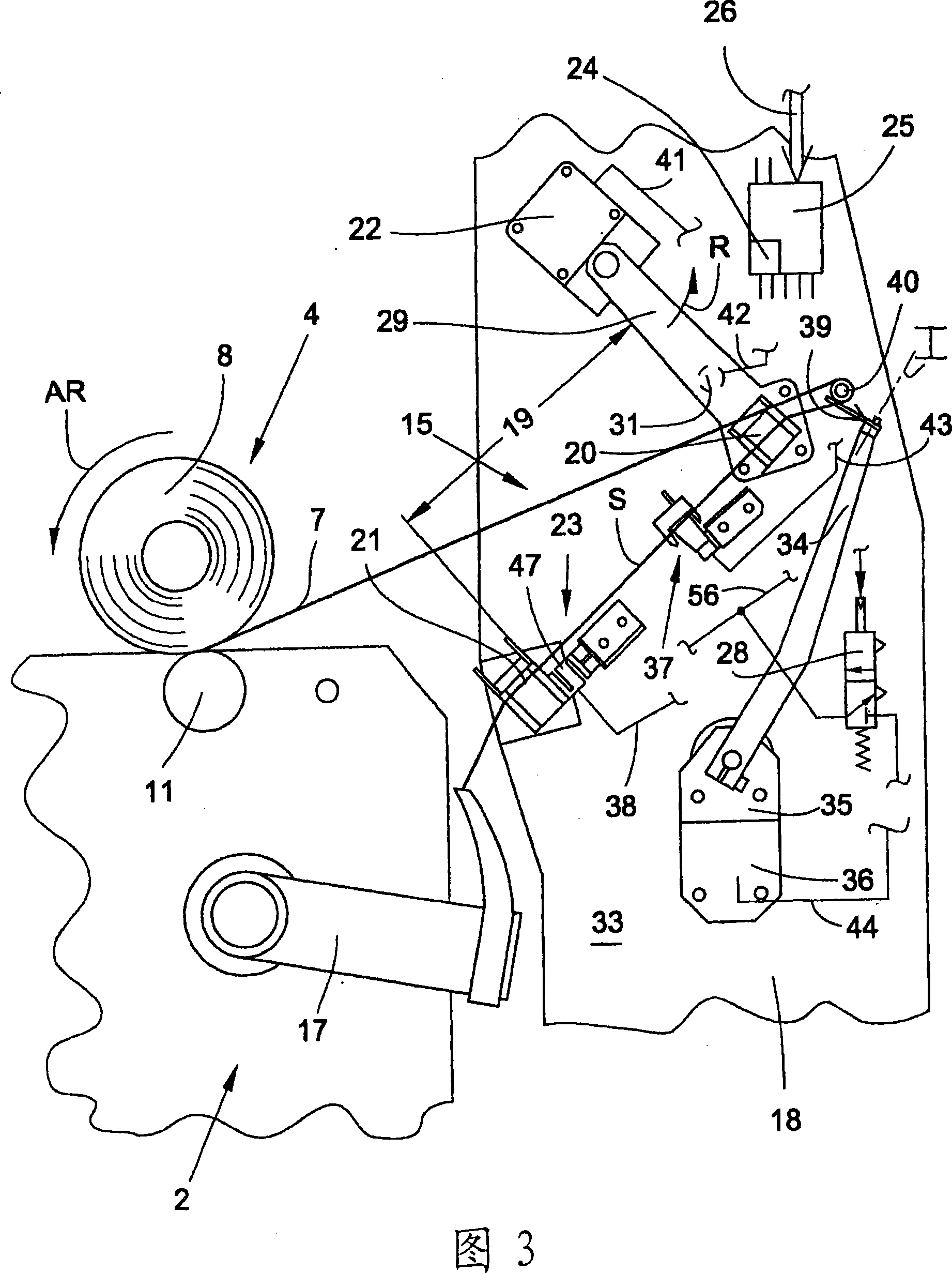

[0031] figure 1 One half of a textile machine 1 (in this embodiment an open-end rotor spinning machine) producing cross-wound bobbins is schematically shown in side view. As known, such textile machines have a plurality of similar workstations 2 between their end frames (not shown). The workstations 2 have, among other things, a spinning unit 3 and a winding mechanism 4 .

[0032] The winding mechanism 4 has, for example, a creel 9 , a bobbin drive roller 11 and a yarn traversing device 16 . In the present example, the bobbin drive roller 11 is acted upon by a drive 13 via a separate motor, which drives the cross-wound bobbins 8 freely rotatably mounted on the creel 9 by means of frictional engagement.

[0033] The fiber strip 6 stored in the spinning pot 5 is processed in the spinning unit 3 into yarns 7 which are then wound onto a winding mechanism 4 to form a cross-wound bobbin 8 . The completed cross-wound bobbins are then transported via a cross-wound bobbin transport ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com