Knobbly bamboo chopsticks and producing method thereof

A manufacturing method and technology of bamboo chopsticks, applied in the direction of manufacturing tools, reed/straw processing, table utensils, etc., can solve the problems of not being able to use knotted bamboo materials, and achieve the effect of improving processing utilization and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

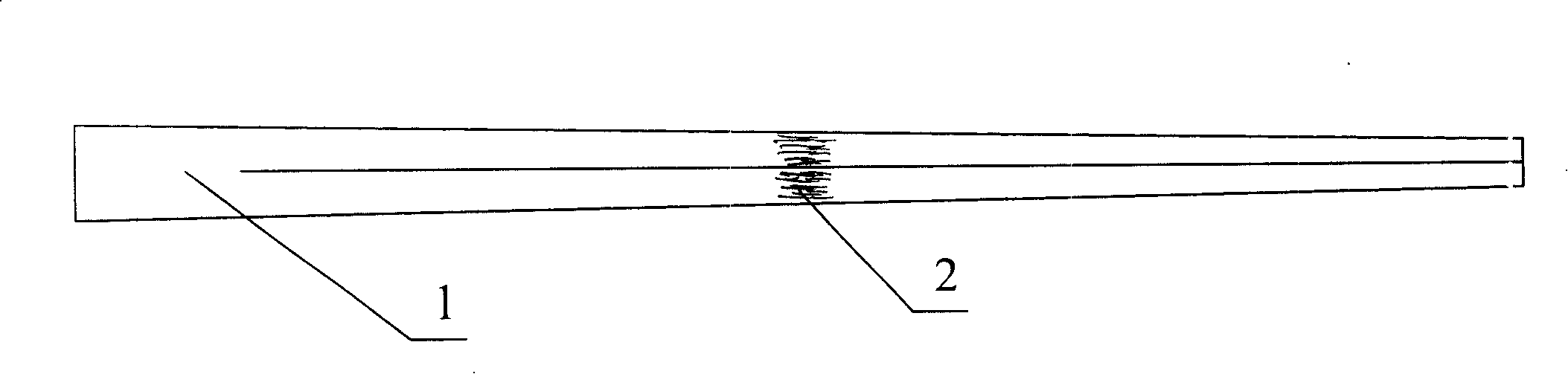

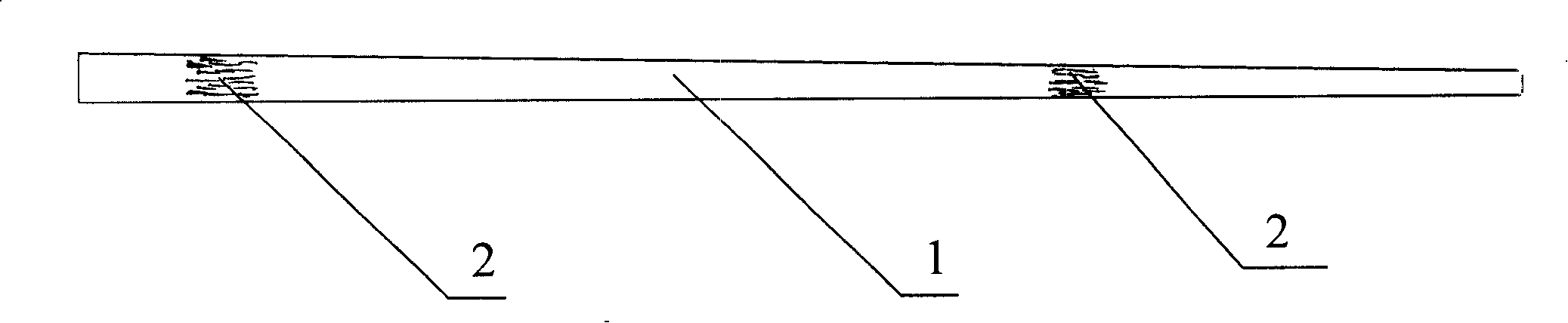

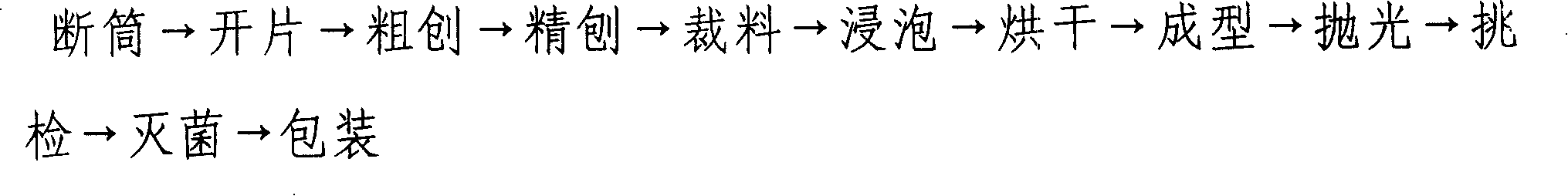

[0014] The present invention will be further described below in conjunction with the accompanying drawings. like figure 1 , figure 2 As shown, a kind of knotted bamboo chopsticks is special in that at least one bamboo knot 2 is arranged on the chopsticks body 1 . If the density of the bamboo joints is high, the number of bamboo joints on the bamboo chopsticks can be more than 2. like image 3 As shown, a manufacturing method of knotted bamboo chopsticks, its production process is: broken barrel→opening→rough wounding→fine planing→cutting→soaking→drying→forming→polishing→picking→sterilization→packaging . The broken tube is to break the original bamboo into a knotted bamboo tube whose length is the sum of the integer multiple of the length of the bamboo chopsticks and the processing allowance according to the availability of bamboo materials, generally more than 1m. The slices can be opened by using a bamboo strip slicer for the production of bamboo flooring, and the bambo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com