Gold slice embroidery computer embroidery machine

An embroidery machine and sequin technology, which is applied to embroidery machines, embroidery machine mechanisms, automatically controlled embroidery machines, etc., can solve the problems of affecting pattern quality, lack of single sequins, inconvenient setting, etc., and achieves the overall compactness of the structure. Good, easy to upgrade and improve, easy to connect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

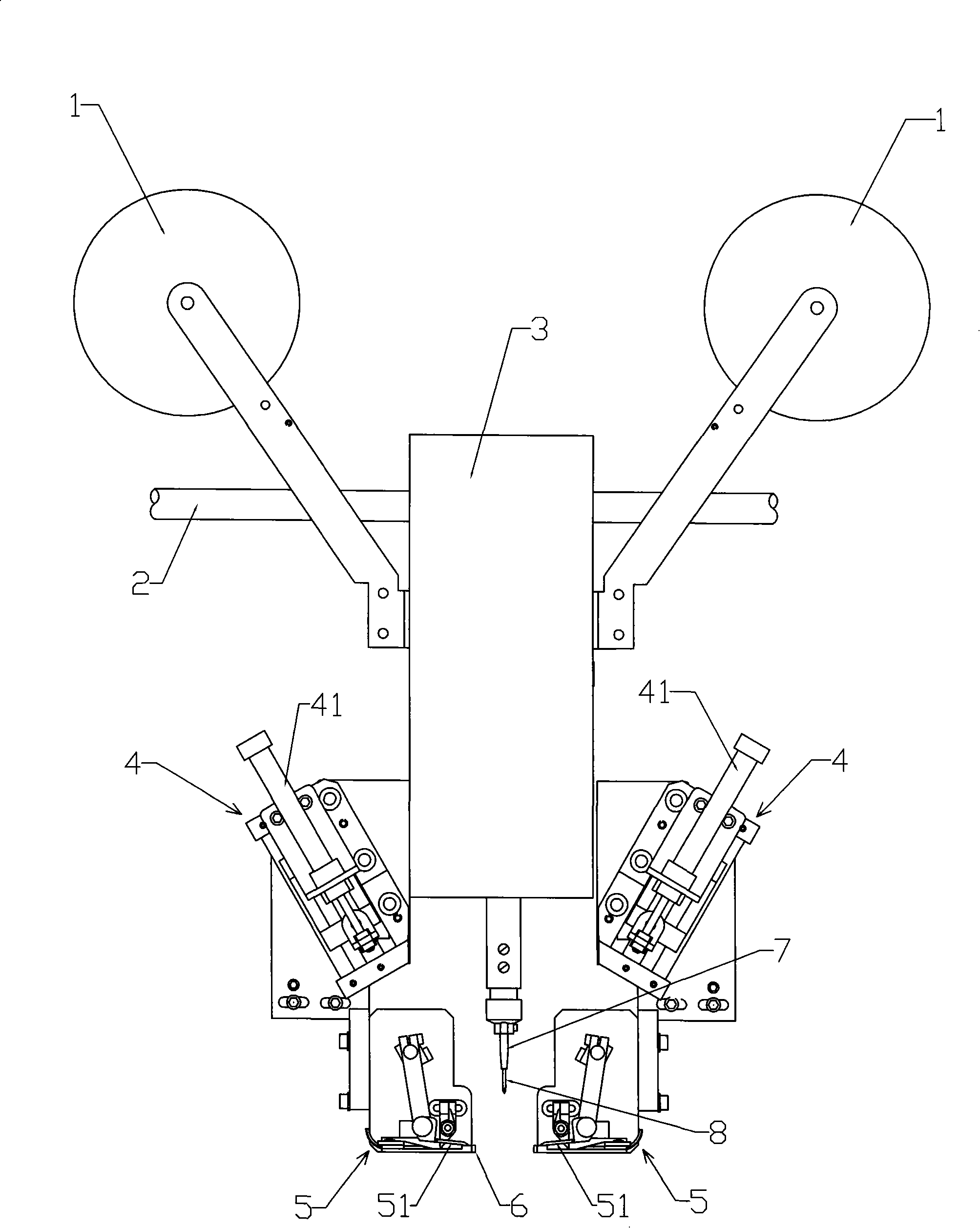

[0027] See figure 1 , figure 2 with image 3 , the structure of the sequin embroidery computerized embroidery machine of the present invention includes a machine head part and a sequin conveying device part, and the two parts are connected together.

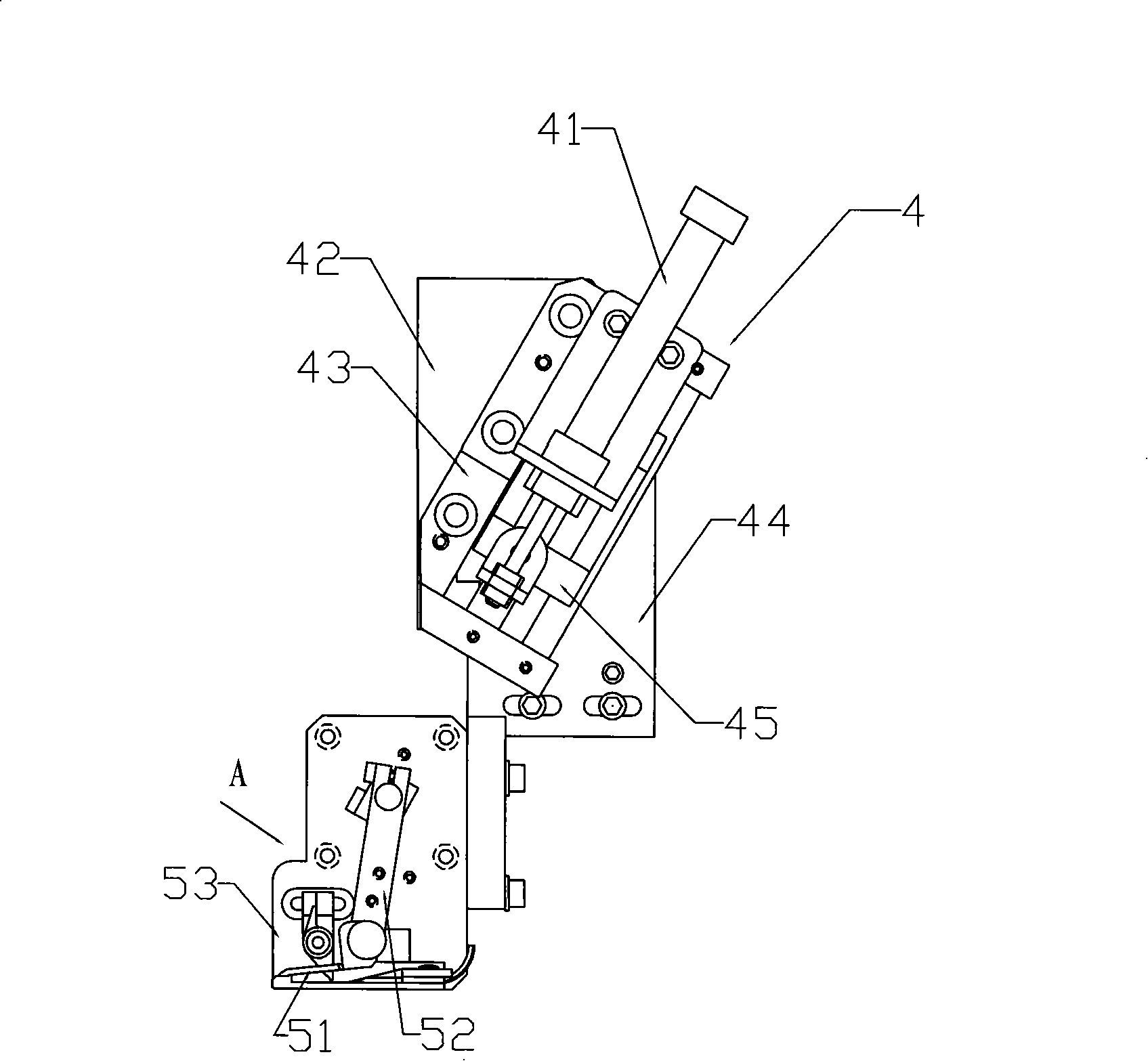

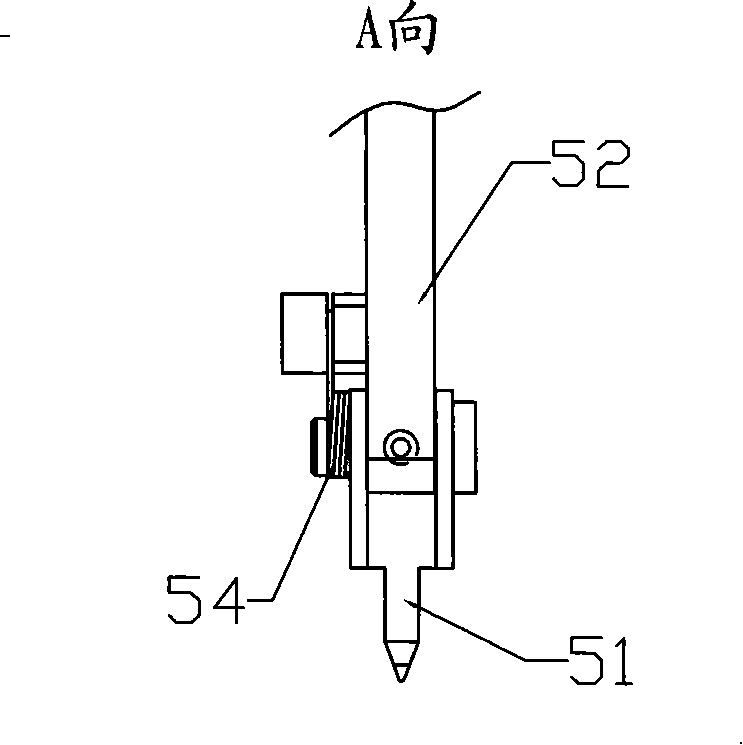

[0028] The gold flake conveying device comprises a lifting mechanism 4 and a feeding mechanism 5 . The lifting mechanism 4 includes a sliding seat 43 and a cylinder 41 arranged on the sliding seat 43 , wherein the sliding seat 43 is obliquely arranged on a connecting plate 42 fixedly connected to the machine head 3 . The piston in the cylinder 41 is fixedly connected with a slide block 45 , which is slidably arranged on a guide rail provided obliquely on the slide seat 43 , and the slide block 45 is fixedly connected with an intermediate connecting plate 44 . The intermediate connecting plate 44 is fixedly connected with a plate-shaped mounting base 53 , the mounting base 53 is located below the intermediate connecting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com