Dichroic guest-host polarizer

A polarizer, dichroic technology, used in polarizing elements, instruments, nonlinear optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

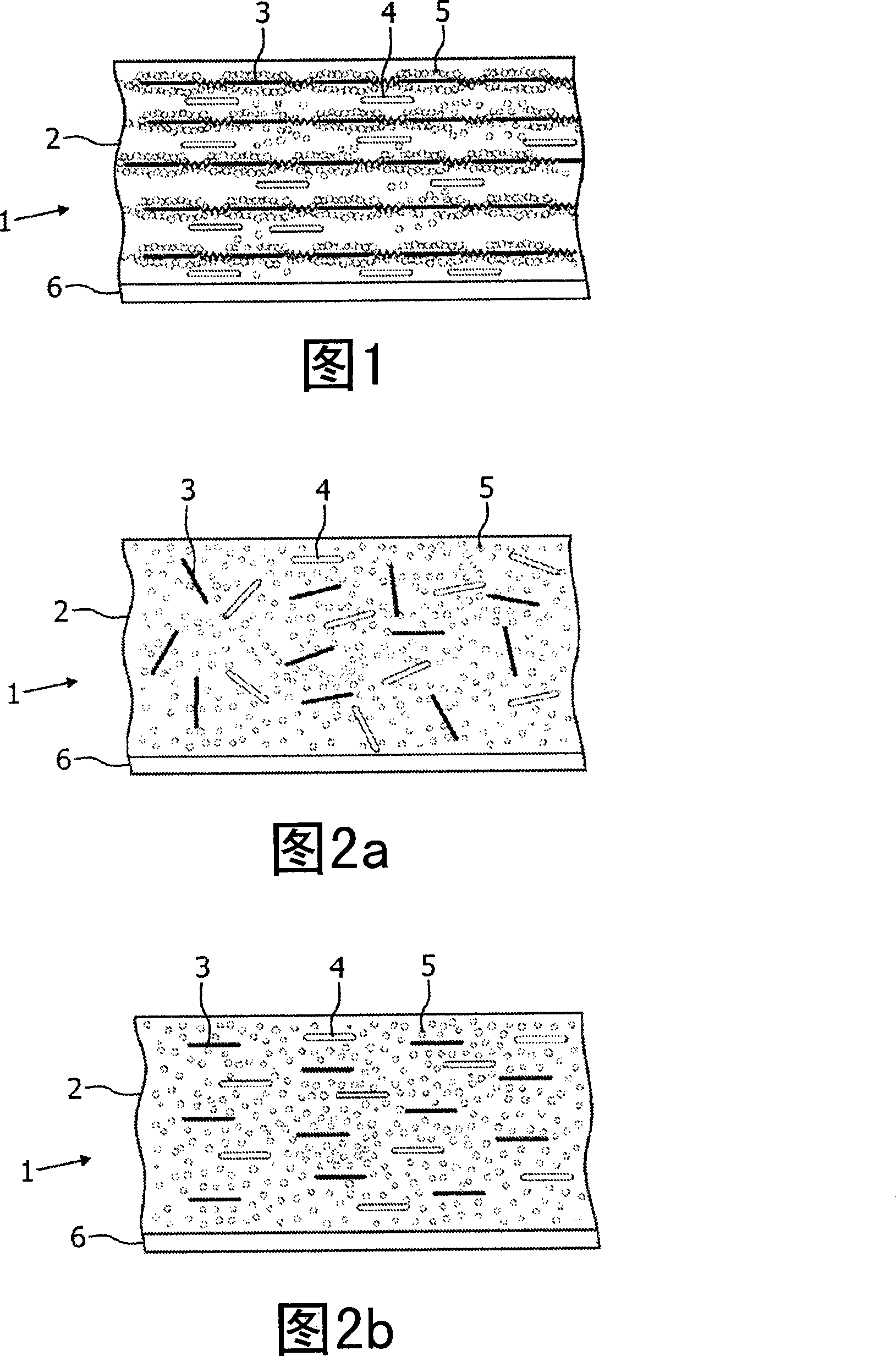

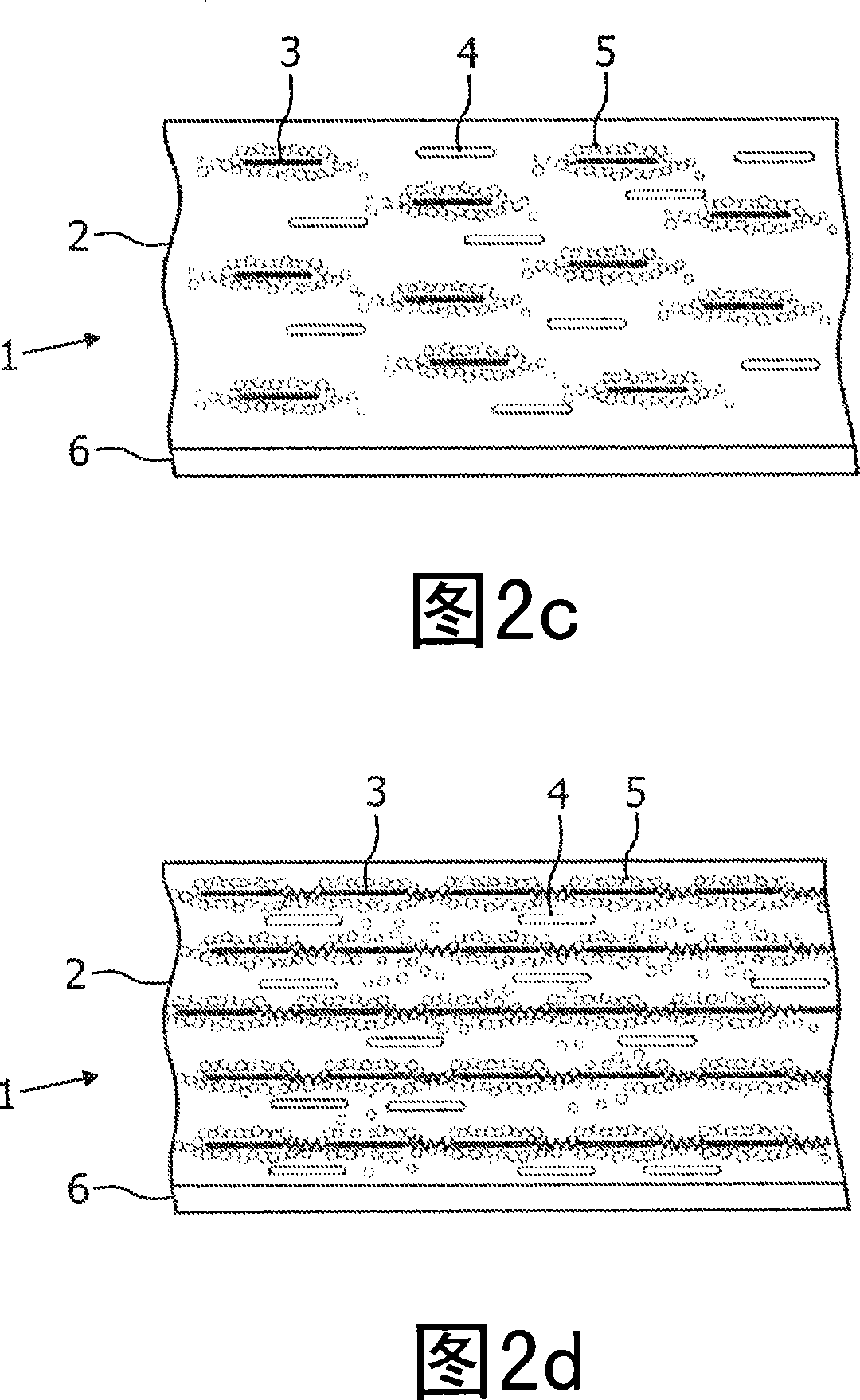

Image

Examples

Embodiment Construction

[0125] Experiment 1

[0126] (not according to the invention)

[0127] A 33% by weight 50 / 50 mixture of the following smectic reactive mesogens V and VI was prepared (1% dichroic dye (NKX2029, Nippon Kankoh Shikiso Kenkyusho), 1% initiator (Irgacure 651, Ciba), 2% surface Active agent and 0.1% inhibitor (p-methoxyphenol)) in chlorobenzene.

[0128]

[0129] The solution was thus spin-coated on a substrate with a rubbed polyimide alignment layer to form a film about 2 microns thick.

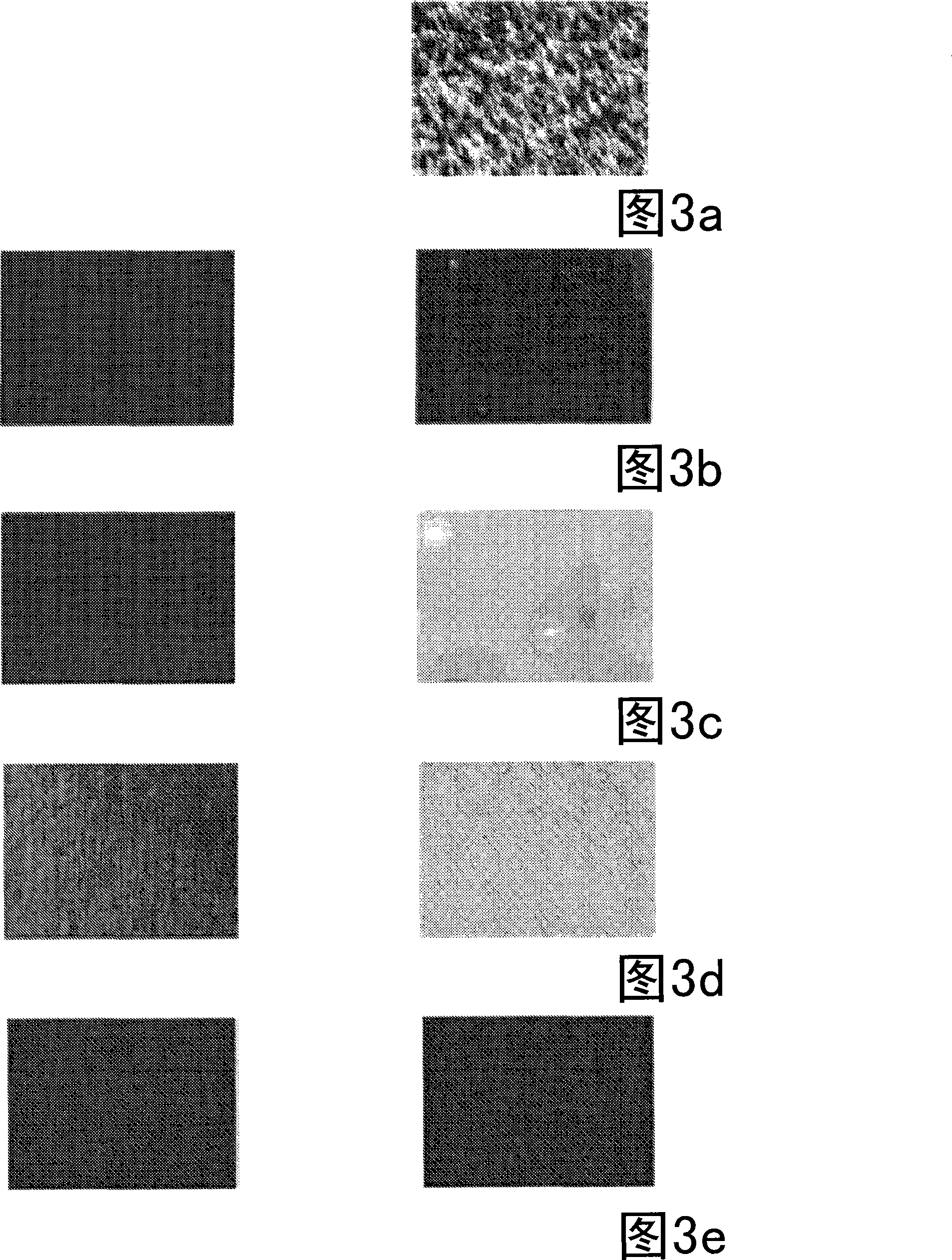

[0130]Figure 3 depicts micrographs of films obtained immediately after spin coating placed between crossed polarizers and at different temperatures. The micrograph on the right shows the image recorded at an angle of 45° between the director of the alignment layer and the polarizer, and the image on the left shows the image recorded at an angle of 0°.

[0131] Immediately after spin-coating, a multi-domain film is obtained in which the orientation of the liquid crystal substrates is predo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com