Full automatic air valve separator

A kind of sorting machine and fully automatic technology, applied in sorting and other directions, can solve the problems of fragile sensors and increased cost of users, and achieve the effects of reducing labor intensity, rapid measurement, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

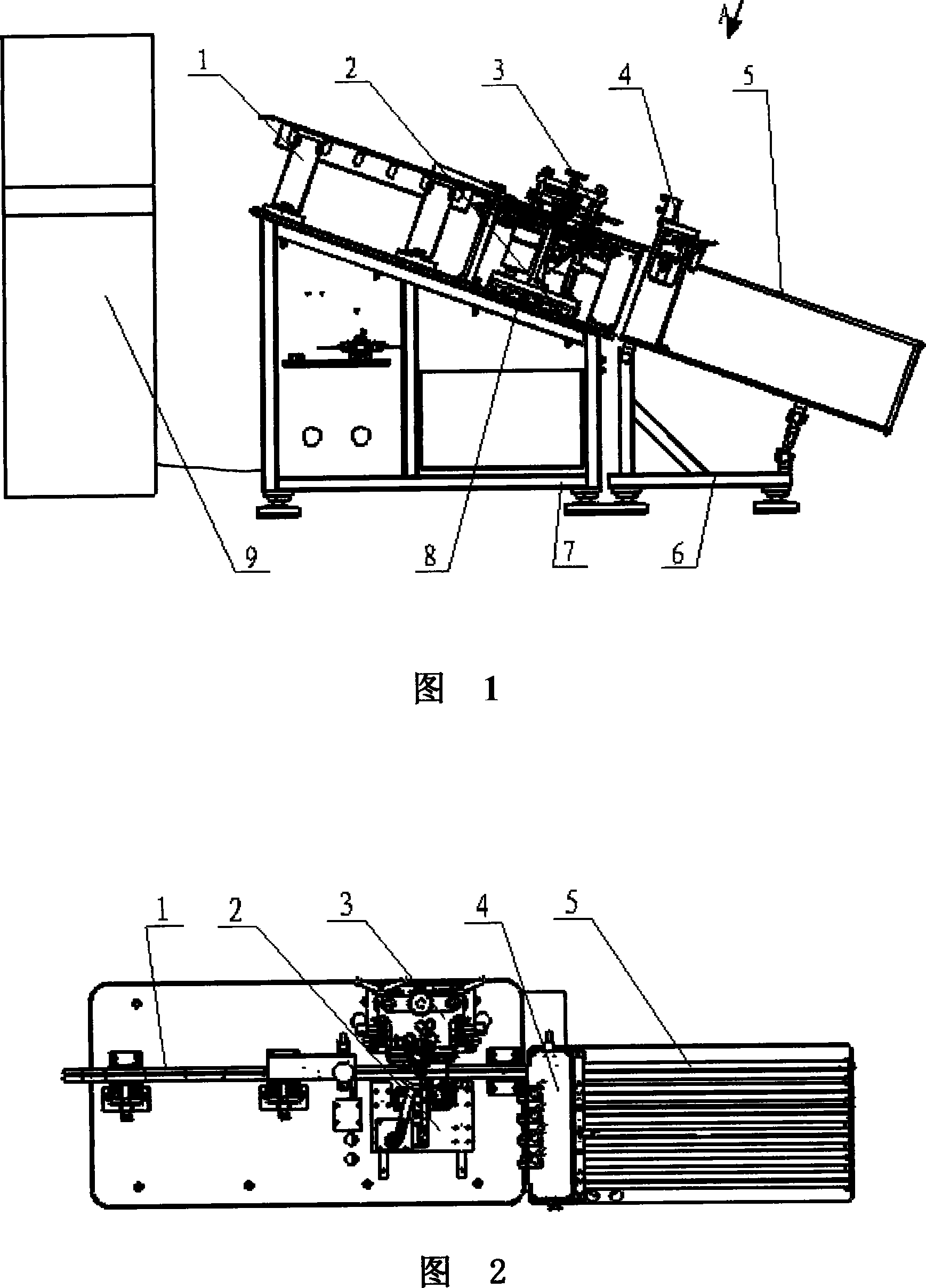

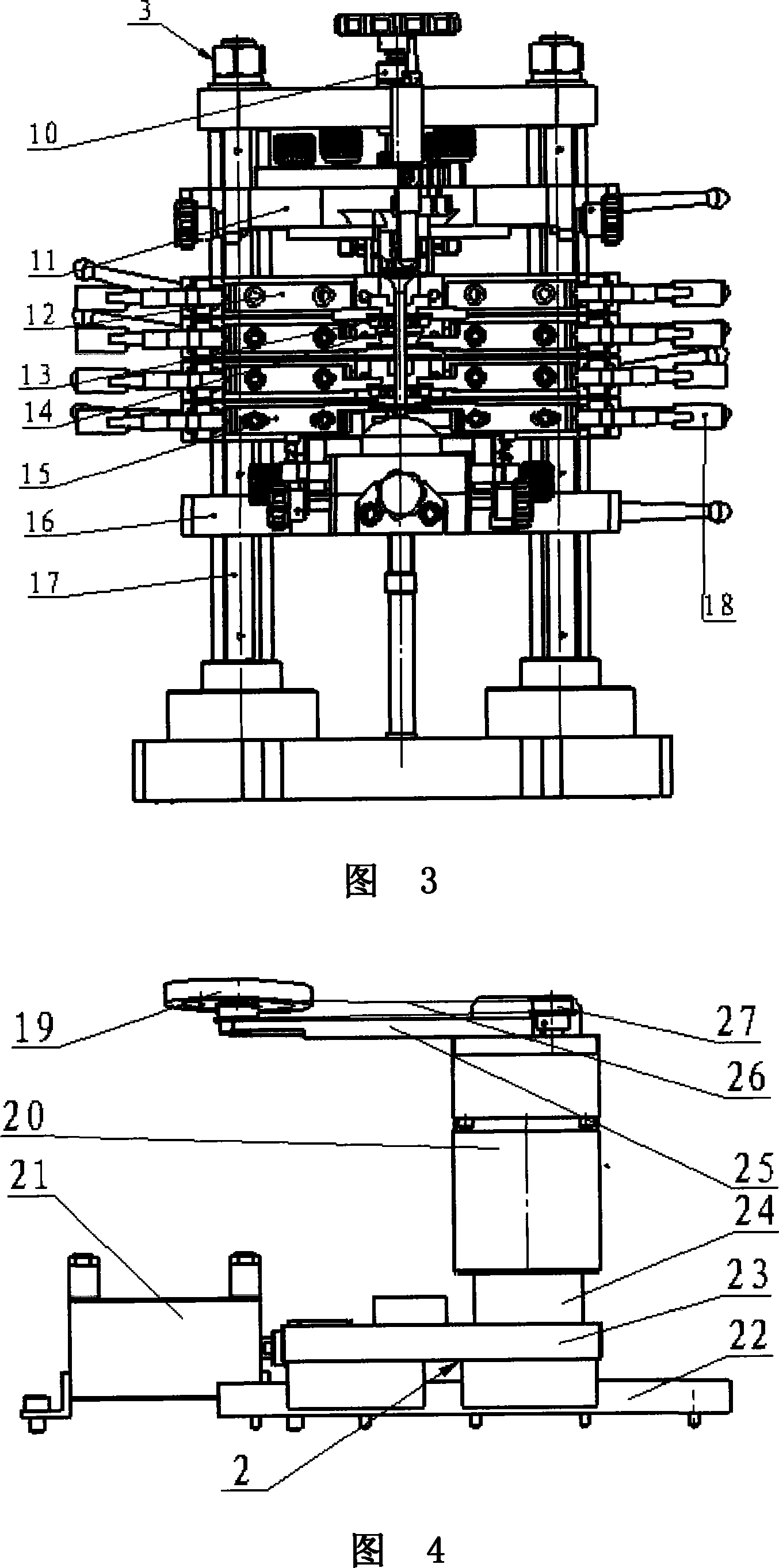

[0018] It can be seen from Figure 1 that a fully automatic valve sorting machine consists of a feeding channel 1, a driving part 2, a measuring part 3, a sorting car 4, a grouping material channel 5, an auxiliary body 6, a main body 7, a main workbench 8, The industrial computer 9 is composed of; as shown in Figure 3: the measuring part 3 is provided with a height adjustment part 10, a measuring plate part 11, a measuring rod part 12, a pushing part 13, a positioning roller 14, a groove measuring part 15, and a measuring end part 16 , column part 17 and width-adjusting part 18; As shown in Figure 4: driving part 2 is made of drive wheel 19, drive motor 20, cylinder 21, guide rail 22, guide rail mounting plate 23, motor mounting plate 24, driving wheel mounting plate 25, Synchronous belt 26, driving wheel 27 form.

[0019] In the driving part 2 as shown in Figure 4, drive wheel 19 is connected with drive wheel mounting plate 25 by bearing; Drive wheel mounting plate 25, drive m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com