Precision optical glass for die pressing

An optical glass, molding technology, applied in the field of optical glass, can solve the problems of poor production economy, high molding temperature, poor transmittance, etc., and achieve excellent chemical stability, good devitrification resistance, and excellent coloring degree. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

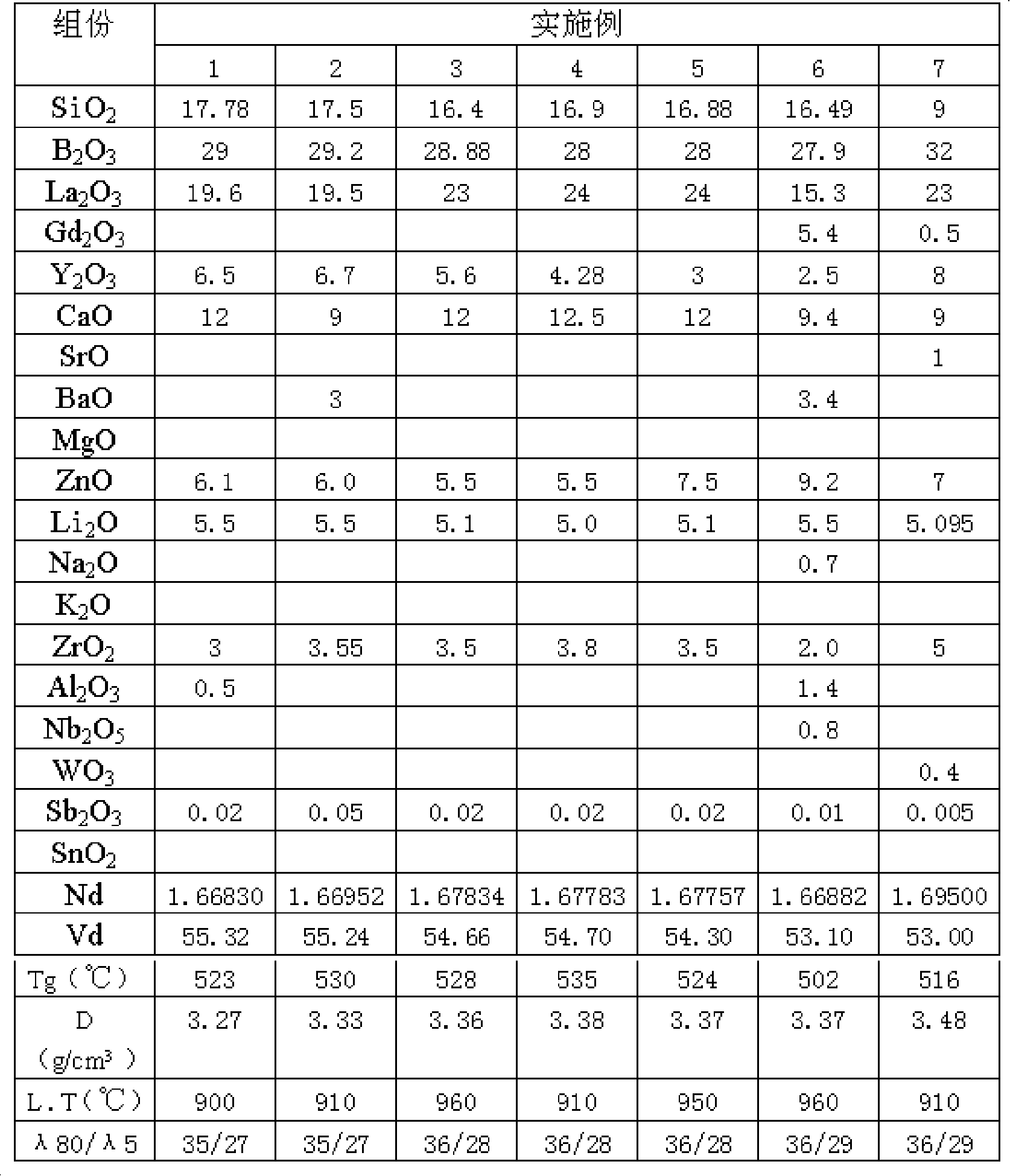

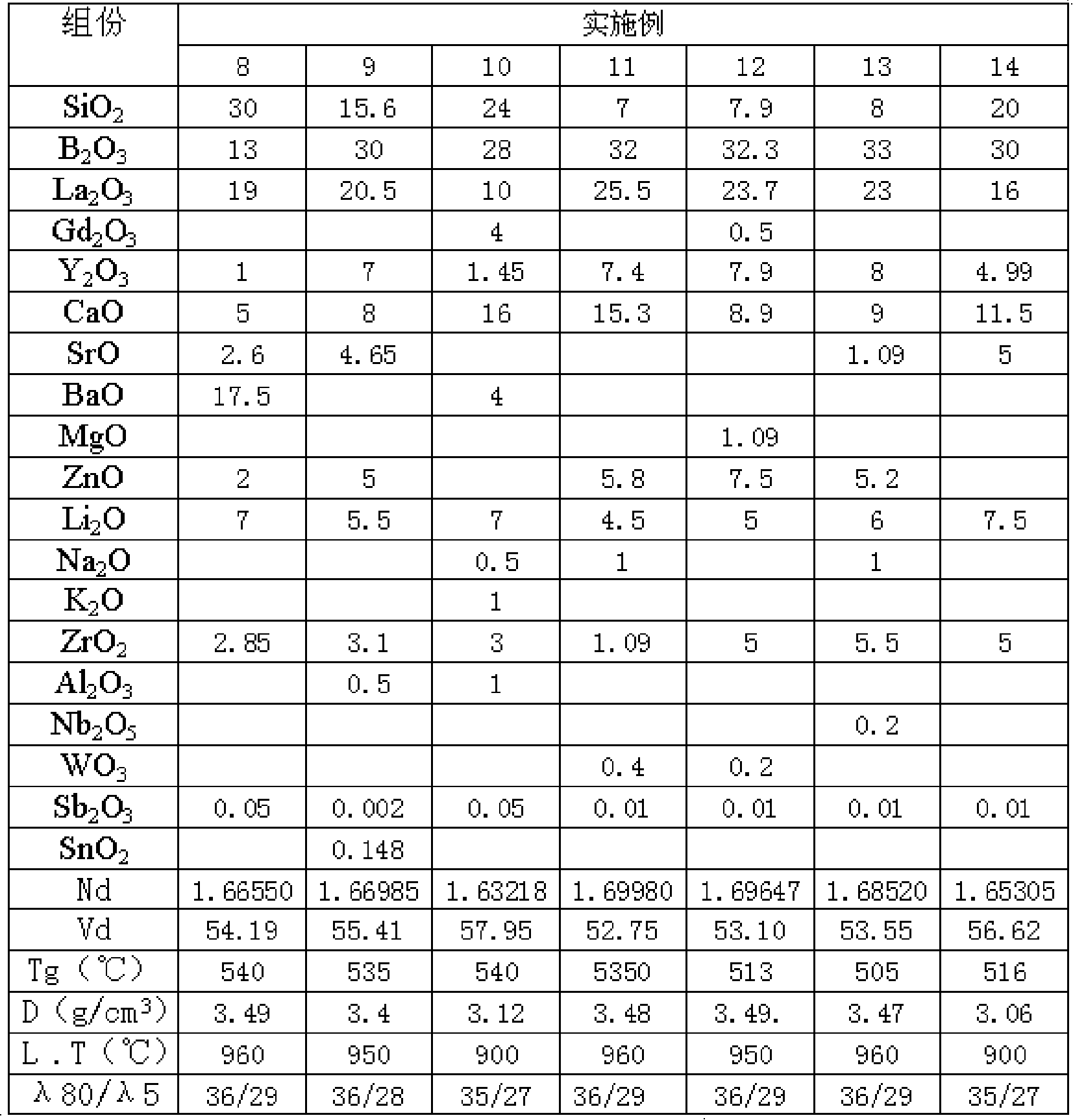

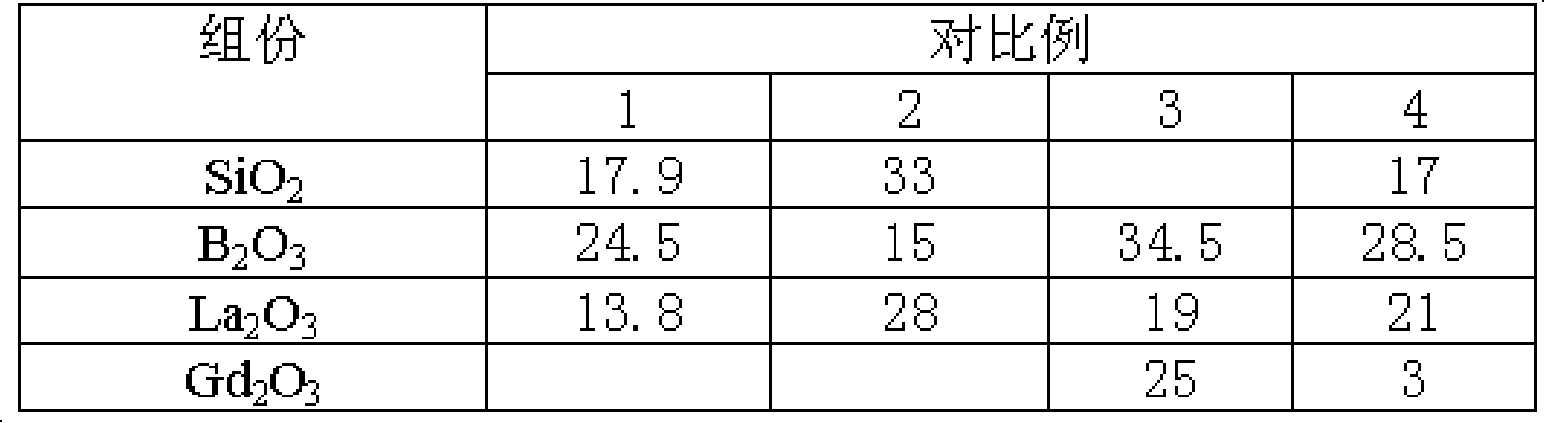

Examples

Embodiment Construction

[0014] SiO 2 Is the main component of glass, SiO 2 It can increase the viscosity of glass and improve the resistance to devitrification of glass. When its content is less than 7% (weight percentage content, the same below), the transmittance and devitrification resistance of the glass are poor, and if it exceeds 32%, the refractive index of the glass decreases and the softening temperature increases.

[0015] B 2 o 3 It is an essential component of glass. When its content is lower than 13%, the softening temperature of the glass is high, the melting performance is poor, and the chemical stability is not ideal. If it is higher than 40%, the devitrification resistance will deteriorate.

[0016] La 2 o 3 It is an important component to maintain the optical constant of the glass, and it plays the role of increasing the refractive index of the glass and reducing the dispersion. When the content is less than 10%, the required optical constant cannot be achieved. When it exceeds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com