Non-floor-bracket construction method for suspension bridge tower frame cross beam

A suspension bridge tower and construction method technology, applied in suspension bridges, bridges, bridge forms, etc., can solve the problems of large engineering volume, large material loss, labor and time-consuming, etc., and achieve the effect of short working hours and less material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

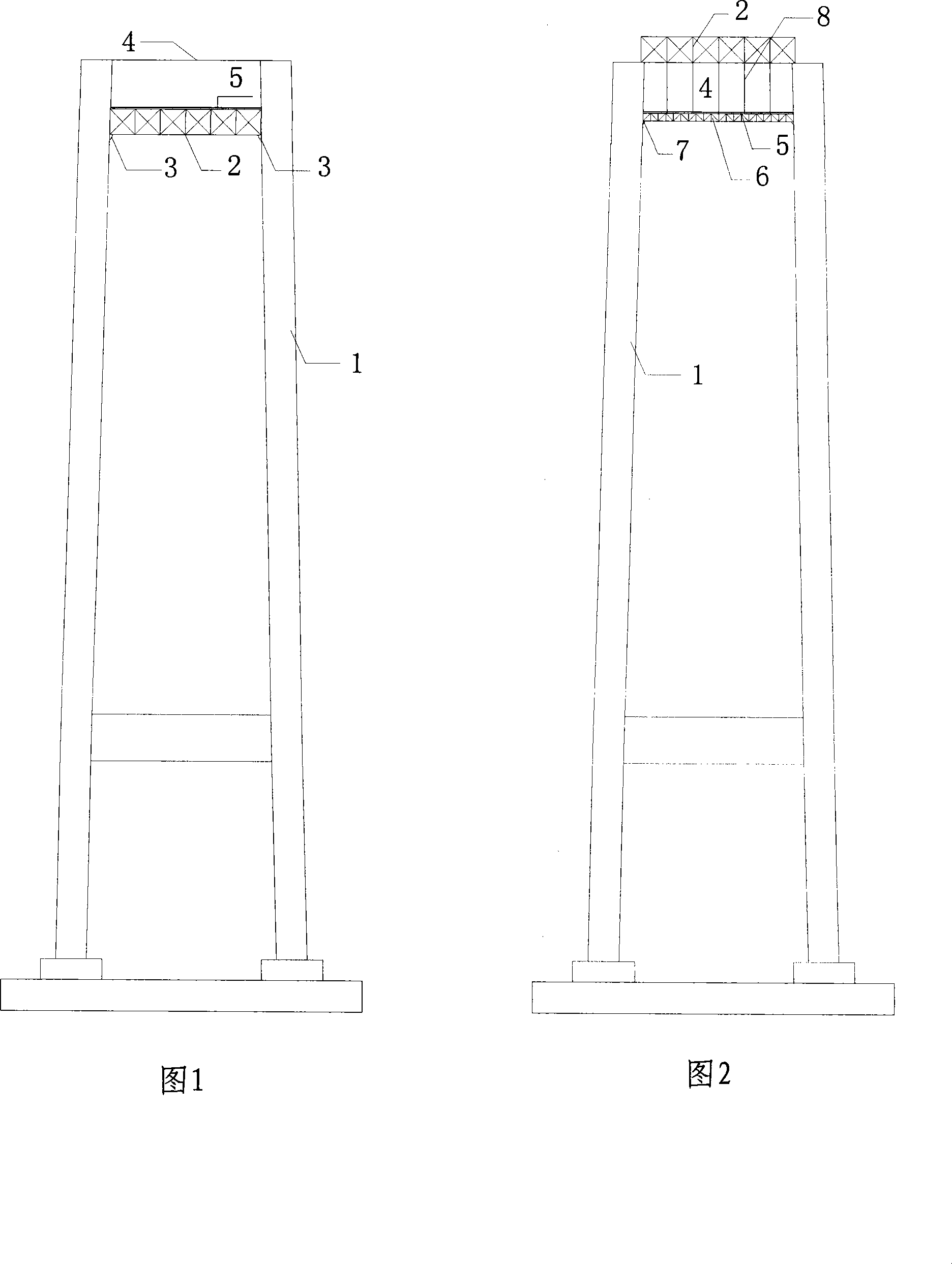

[0011] As shown in Figures 1 and 2, the construction method of the suspension bridge tower beam without floor support of the present invention is that the tower beam relies on the load-bearing steel truss construction. As shown in Figure 1, the "corbel" is first installed on the tower column, then the prefabricated load-bearing steel truss is hoisted on the corbel, and then the construction platform is laid on the load-bearing steel truss, and the tower beam construction is carried out on the platform; Figure 2 As shown, the prefabricated load-bearing steel truss is hoisted and supported on the top of the tower column, and the "bottom-hanging working platform" is hung with the hanging connector, and the two ends of the "bottom-hanging working platform" are supported on the preset auxiliary cattle. On the legs to strengthen the support, the tower beam construction is carried out on the hanging working platform.

[0012] The above descriptions are only preferred embodiments of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com