Material carrying mechanism for refuse burning furnace

A garbage incinerator and sleeve technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problem of incomplete combustion of garbage, and achieve the effect of simple structure, accelerated combustion speed and good combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

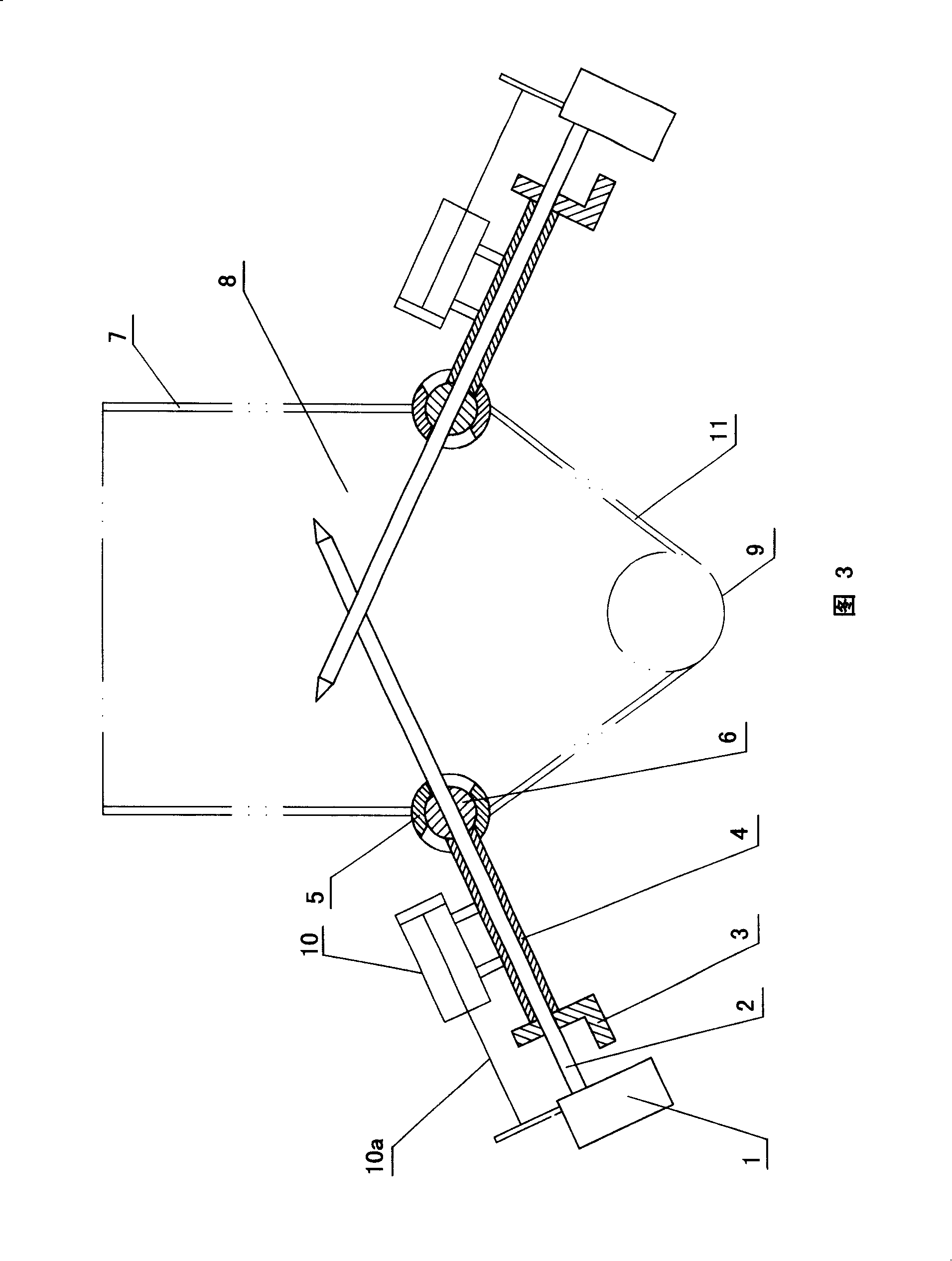

[0011] The present invention is further described below in conjunction with embodiment and accompanying drawing.

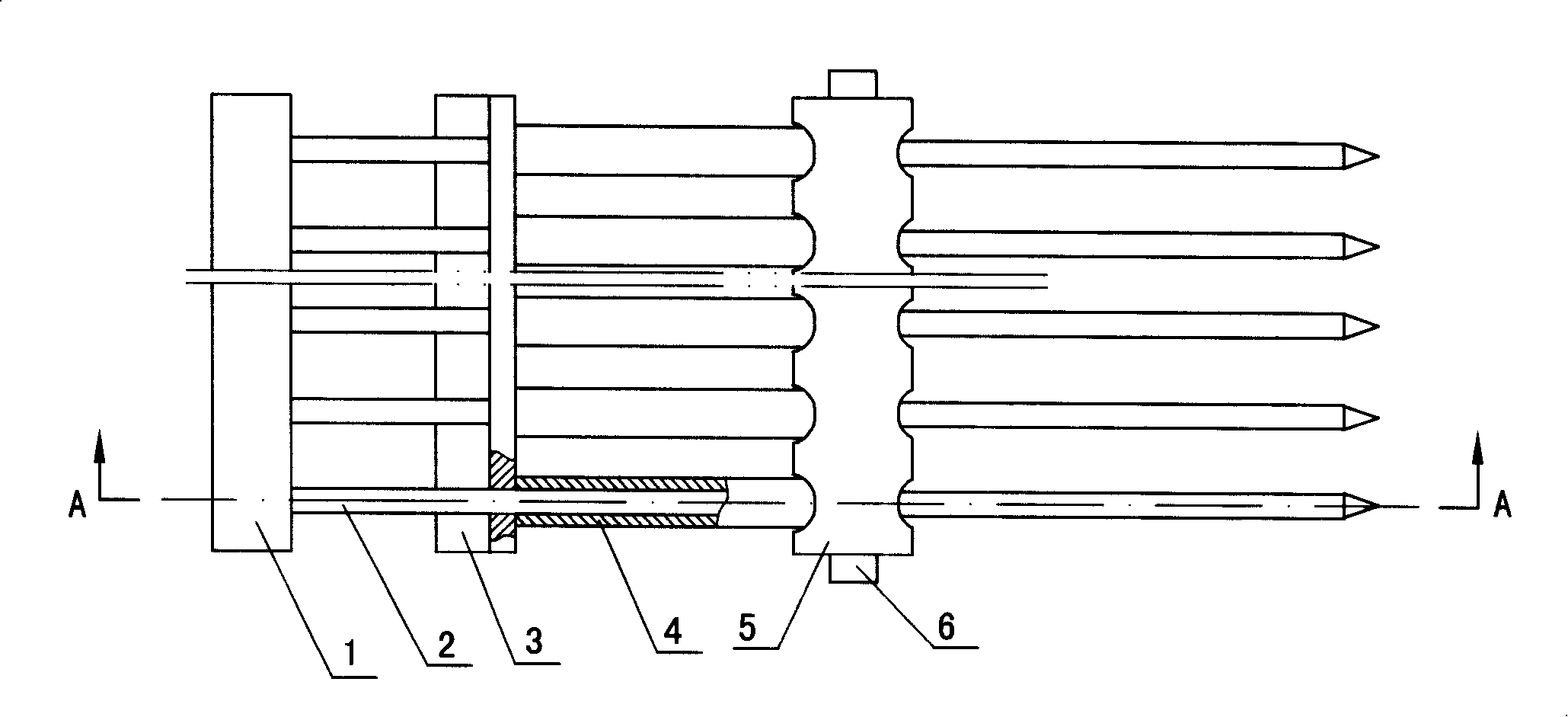

[0012] see figure 1

[0013] The supporting mechanism of the garbage incinerator provided by the present invention includes a support 1, a sleeve 5, a rotating shaft 6 and more than two poles 2 arranged in parallel, one end of the pole 2 is fixed on the support 1, and the rotating shaft 6 is installed in sleeve 5.

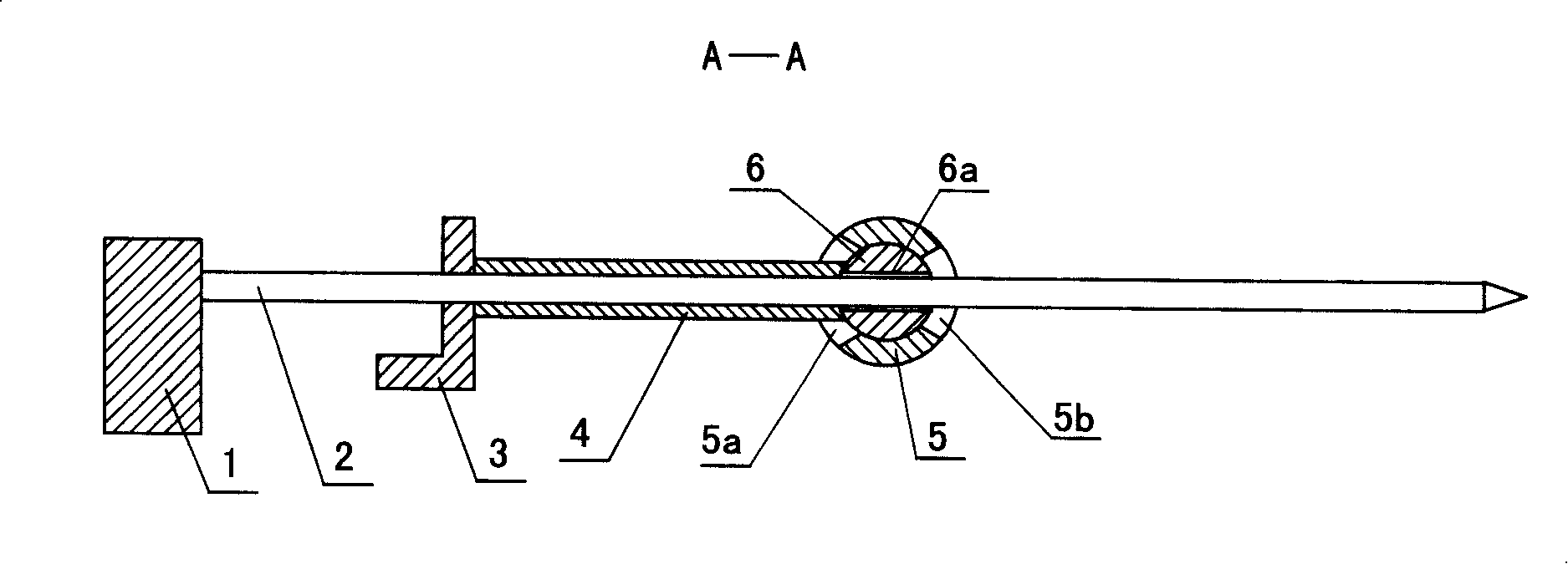

[0014] see figure 2

[0015] The rotating shaft 6 is provided with through holes 6a corresponding to the number and positions of the poles 2, and the sleeve 5 is provided with two rows of one-to-one relative openings 5a and 5b. Each through hole 6a on the rotating shaft 6 is connected to the sleeve 5 Every two opposite ports 5a and 5b communicate with each other, and each strut 2 passes through a through hole 6a on the rotating shaft 6 and every two opposite ports 5a and 5b on the sleeve 5 .

[0016] Additionally, by figure 1 , figure 2 It can...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap