Active noise reduction method and device

A technology of noise reduction and infrasound source, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of complex, unobstructed degree of exhaust noise, difficult noise signal elimination, etc., achieve less distortion, reduce noise, and achieve ideal results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

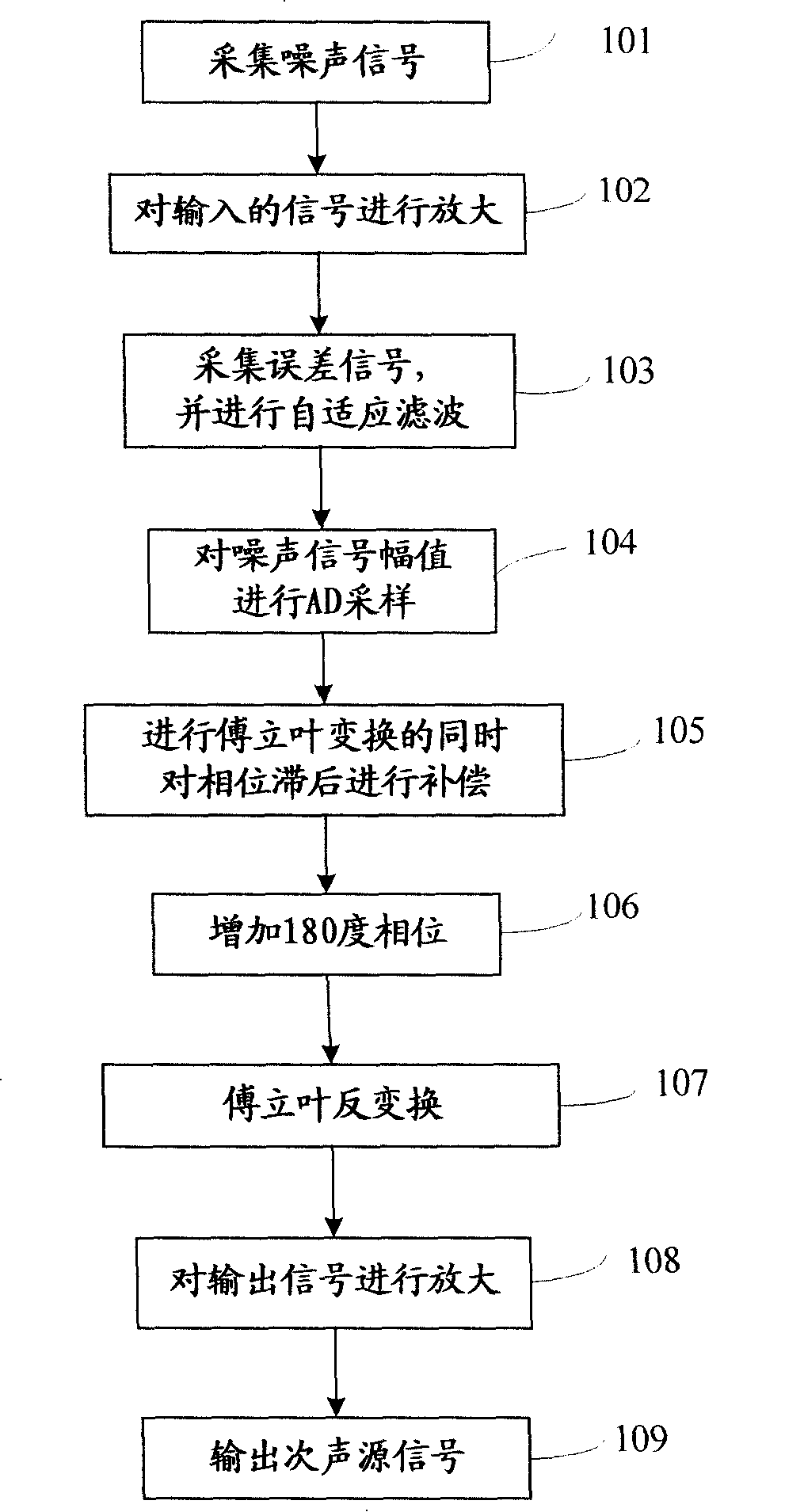

[0043] Embodiment one is an active noise reduction method, below in conjunction with the attached figure 1 The content of the embodiment is described in detail. figure 1 It is the control flowchart of this embodiment. The sound field area to be controlled can be the air inlet or outlet of air conditioner cabinets, commercial air conditioner indoor units, range hoods, or other straight passages with noise.

[0044] Step 101: Firstly, the noise source signal in the noise field is collected. The waveform signal of the noise source is collected through a microphone or other collection devices such as sensors capable of collecting acoustic vibration signals. The collection device is arranged on the central axis of the noise source pipeline, and can collect waveform signals close to real noise to the greatest extent. , and at the same time, preliminary filtering can be performed by means of software or hardware filtering to filter out the DC signal.

[0045] Step 102: Amplify the...

Embodiment 2

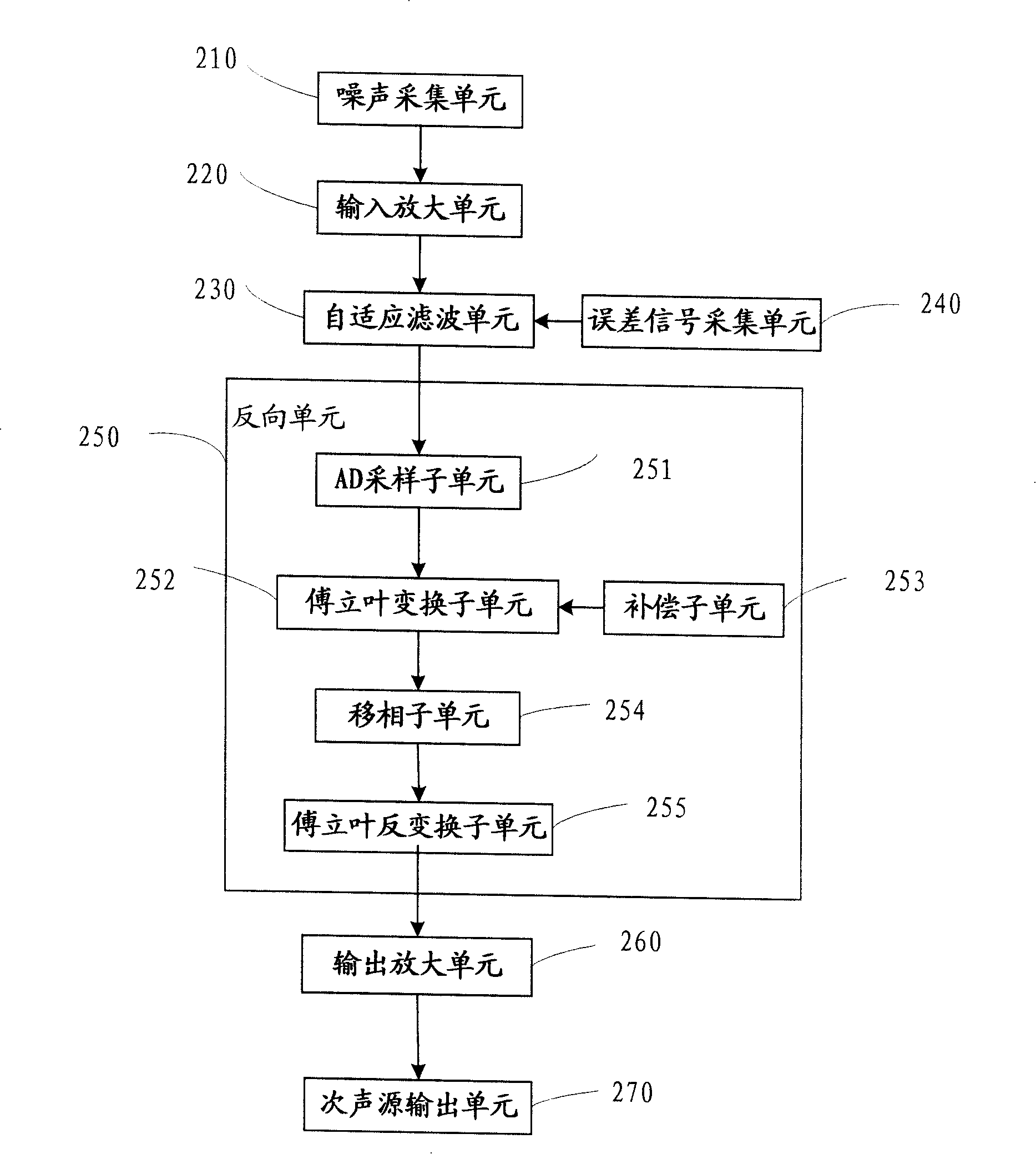

[0065] Embodiment two is an active noise reduction device, the following in conjunction with the attached image 3 The content of the embodiment is described in detail. image 3 It is a block diagram of the device in this embodiment.

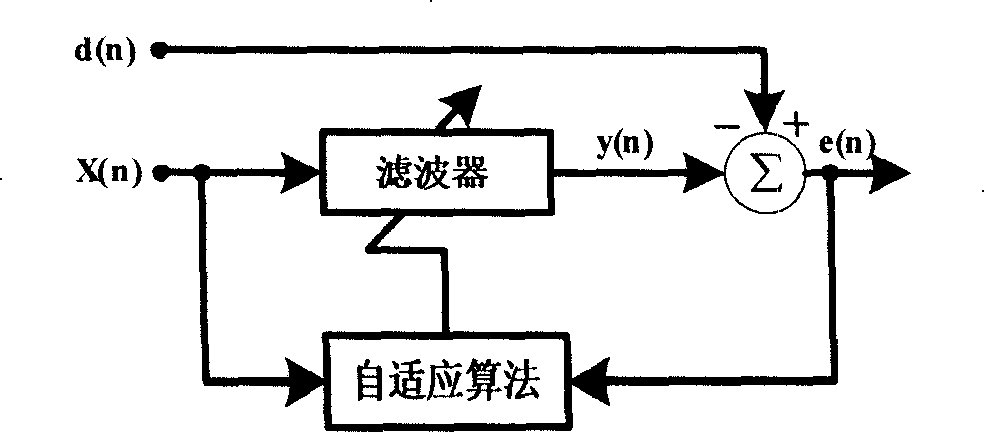

[0066] The noise collection unit 210 uses a microphone or other sensor noise sources capable of collecting acoustic vibration signals to send out signals, and sends the collected noise source signals to the input amplification unit 220 for amplification processing, and the amplified noise source signals are then amplified. Send into the adaptive filtering unit 230, an error signal acquisition circuit 240 collects the noise source signal in the noise field and the superimposed error signal of the subsound source signal, also sends in the described adaptive filtering unit 230, the described adaptive filtering unit 230 implements the filtering process adaptively according to the above two signals, and can continuously correct while filtering out s...

Embodiment 3

[0068] Embodiment three such as Figure 4 As shown in , the pipe 1 in the figure is the sound field area to be controlled, which can be the air inlet or outlet of the air conditioner cabinet, commercial air conditioner indoor unit, range hood, or other straight passages with noise. Pipeline 1 is provided with a microphone MIC for collecting noise signals and a speaker SPK for outputting secondary sound field signals. Since the pipes that generate noise on electrical appliances are relatively regular, a set of microphones and speakers can generally be used and set on the main axis of pipe 1. In terms of location, multiple sets of microphones and speakers can also be used in application environments with complex sound fields. Figure 5 It is the circuit schematic diagram of the device of the present invention, the noise source signal collected directly by the microphone MIC is usually relatively weak, so the collection output of the microphone MIC is filtered and blocked by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com