3 freedom degree high precision positioning movement device and positioning method

A technology for locating motion tables and positioning methods, which is applied to workbenches, instrument parts, instruments, etc., can solve problems such as lack of clear instructions, positioning dead zones, and small ranges, and achieve simple and reasonable positioning steps. High positioning accuracy and the effect of eliminating dead zones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0066] As shown in Figure 16, the three-degree-of-freedom high-precision positioning motion platform device provided by the present invention includes a motion platform 7, and is characterized in that it also includes:

[0067] A horizontal lead screw motor 4, which is arranged along the horizontal X direction of the motion platform 7, and is connected to the vertical side of the motion platform 7; a horizontal Home position sensor 1 is correspondingly arranged along the direction in which the horizontal lead screw motor 4 is set;

[0068] The first vertical lead screw motor 5 is arranged along the vertical Y direction of the motion platform 7 and is connected to the horizontal side of the motion platform 7; along the setting direction of the first vertical lead screw motor 5, a first vertical Home is correspondingly arranged. position sensor 2;

[0069] The second vertical lead screw motor 6, which is arranged along the vertical Y direction of the moving platform 7, is connec...

Embodiment 1

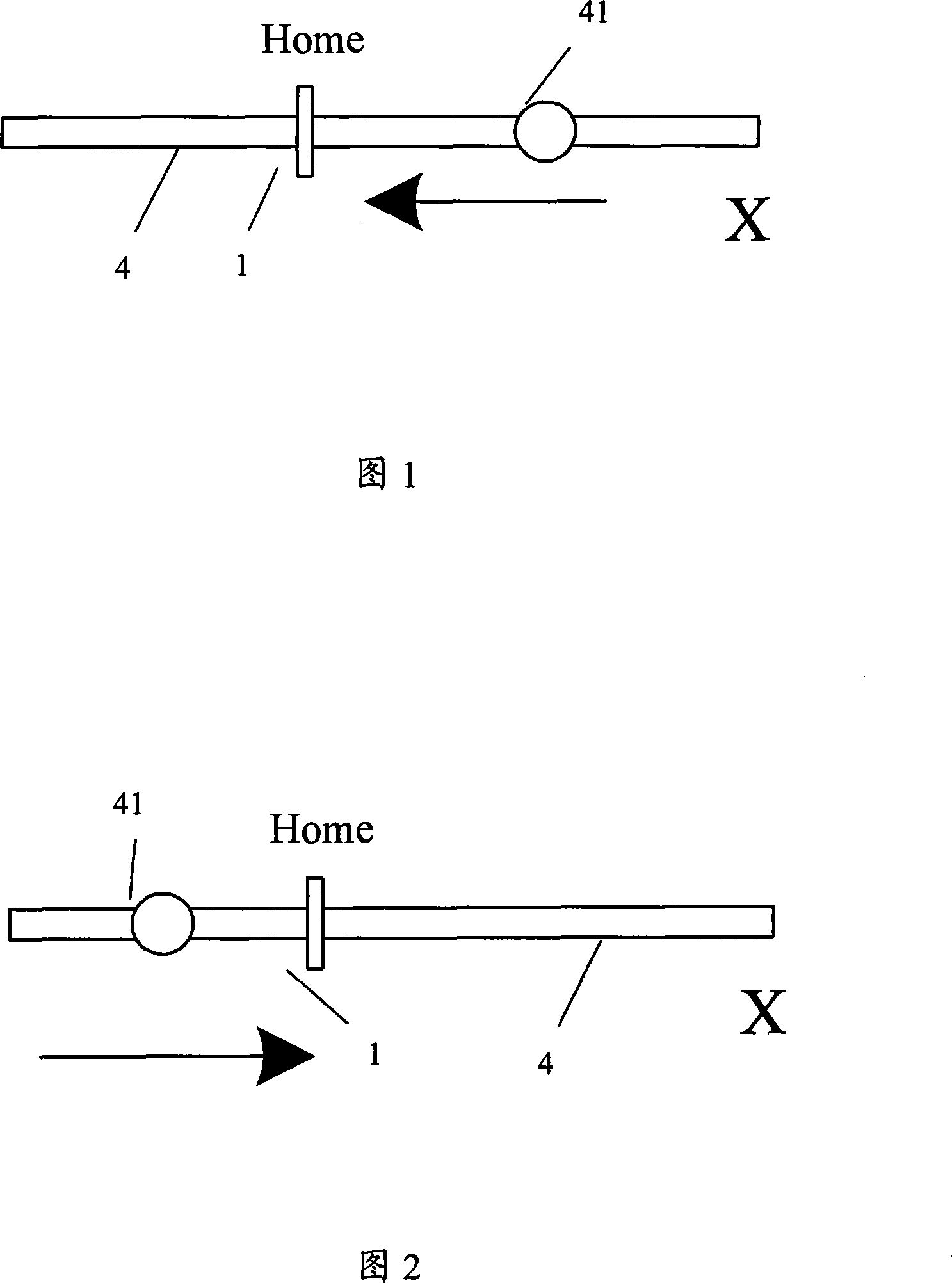

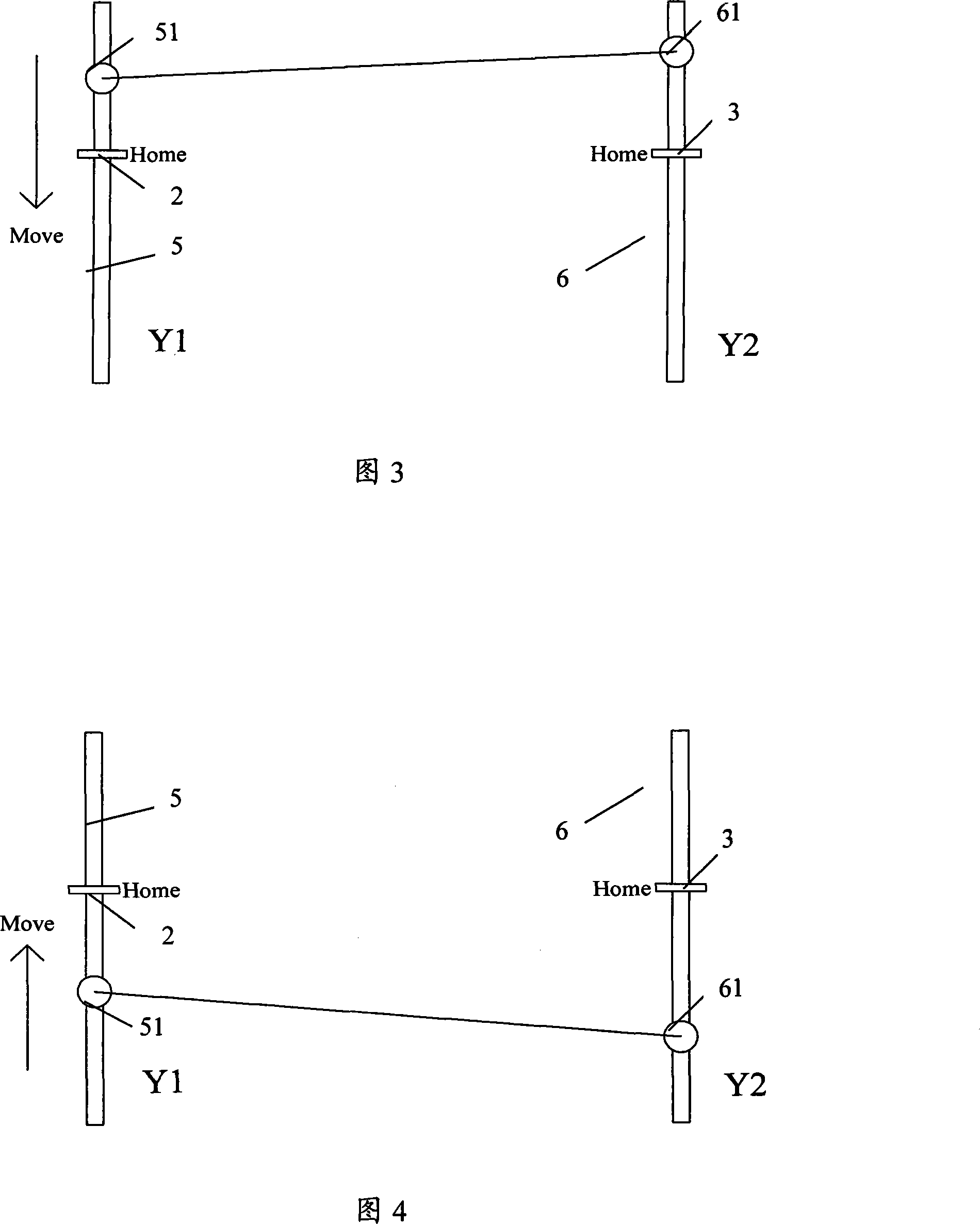

[0105] In this embodiment 1, first adjust the coordinate position of the motor encoder 41 on the horizontal X direction of the motion table device to as shown in Figure 1, and adjust the coordinate positions of the two motor encoders 51 and 61 in the vertical Y direction Adjust it as shown in Figure 3, and then start the three motors for servo control; the specific process of positioning the motion platform device is as follows:

[0106] Step 1. Measure and obtain the relative positional relationship between the encoders on each lead screw motor and its corresponding Home position sensor as described above, that is, the coordinate positional relationship of the current moving table device in the horizontal X direction and vertical Y direction is as follows: Shown in Figure 1 and Figure 3;

[0107] Step 2, as shown in Figure 1, since the horizontal encoder 41 is located on the right side of the horizontal Home position sensor 1, then move the motion platform 7 to the left until...

Embodiment 2

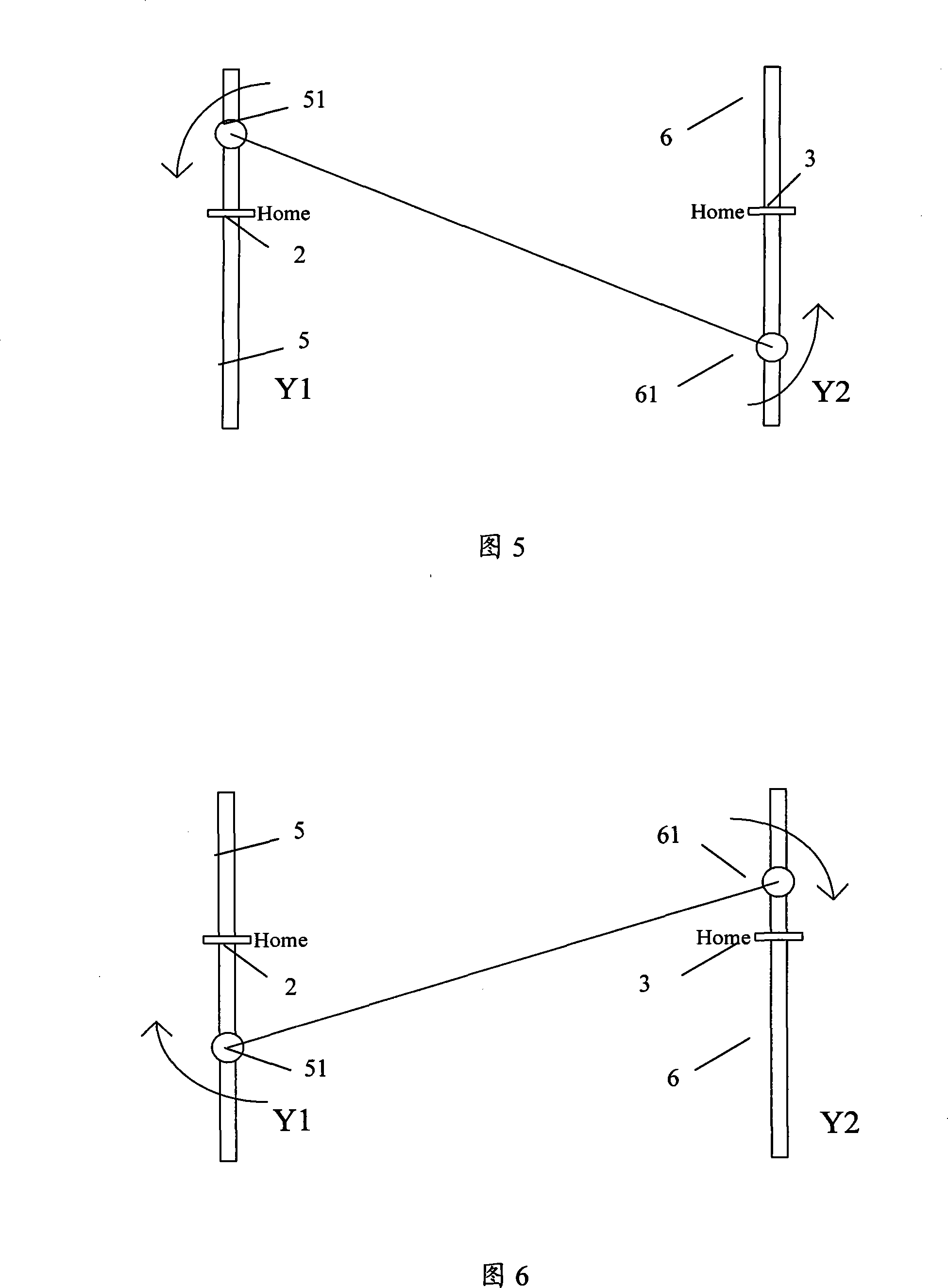

[0115] In this embodiment 2, first adjust the coordinate position of the motor encoder 41 on the horizontal X direction of the motion table device to as shown in Figure 2, and adjust the coordinate positions of the two motor encoders 51 and 61 in the vertical Y direction Adjust it as shown in Figure 5, and then start the three motors for servo control; the specific positioning process of the motion platform device is as follows:

[0116] Step 1. Measure and obtain the relative positional relationship between the encoders on each lead screw motor and its corresponding Home position sensor as described above, that is, the coordinate positional relationship of the current moving table device in the horizontal X direction and vertical Y direction is as follows: Shown in Figure 2 and Figure 5;

[0117] Step 2, as shown in Figure 2, since the horizontal encoder 41 is positioned at the left side of the horizontal Home position sensor 1, then move the motion platform 7 to the right un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com