Plastic-shell electromechanical integrated three-phase AC motor protector with energy storage and impact device

An impact device and three-phase AC technology, applied in protection switches, emergency protection devices, emergency protection circuit devices, etc., can solve the problems of motor failure, inconvenient installation, and large space occupation, and achieve complete protection functions and convenient installation and debugging. , to avoid the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

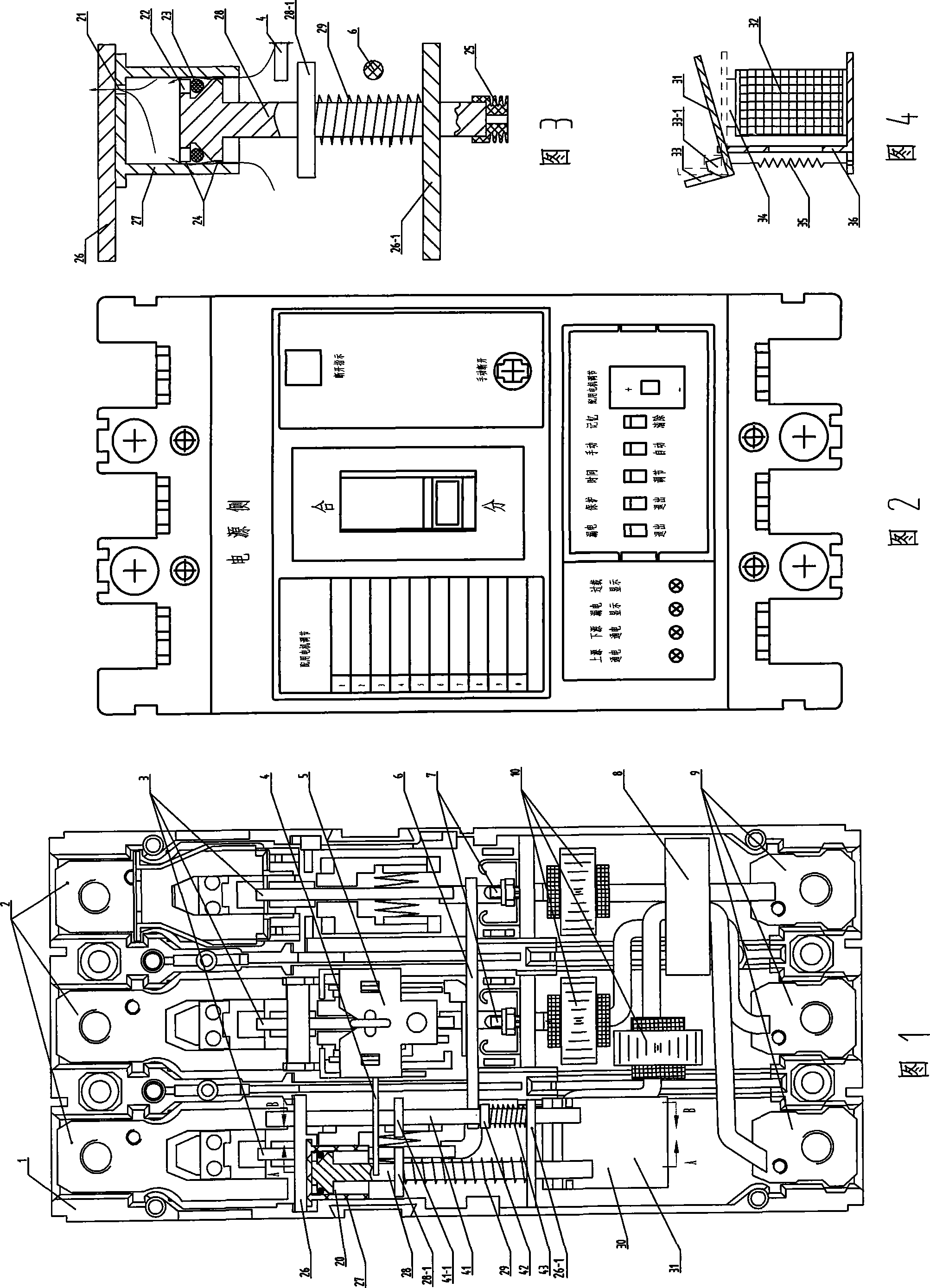

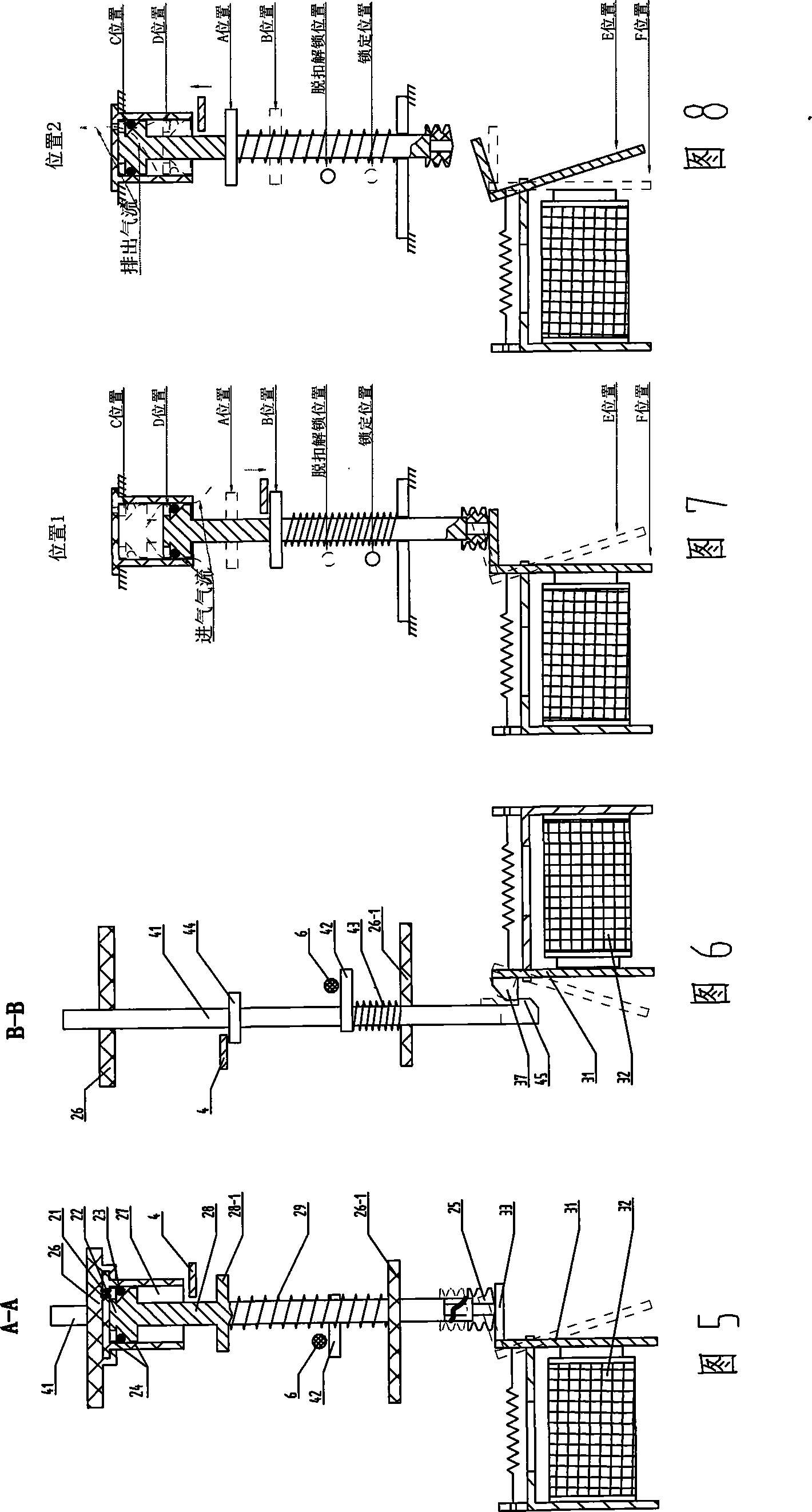

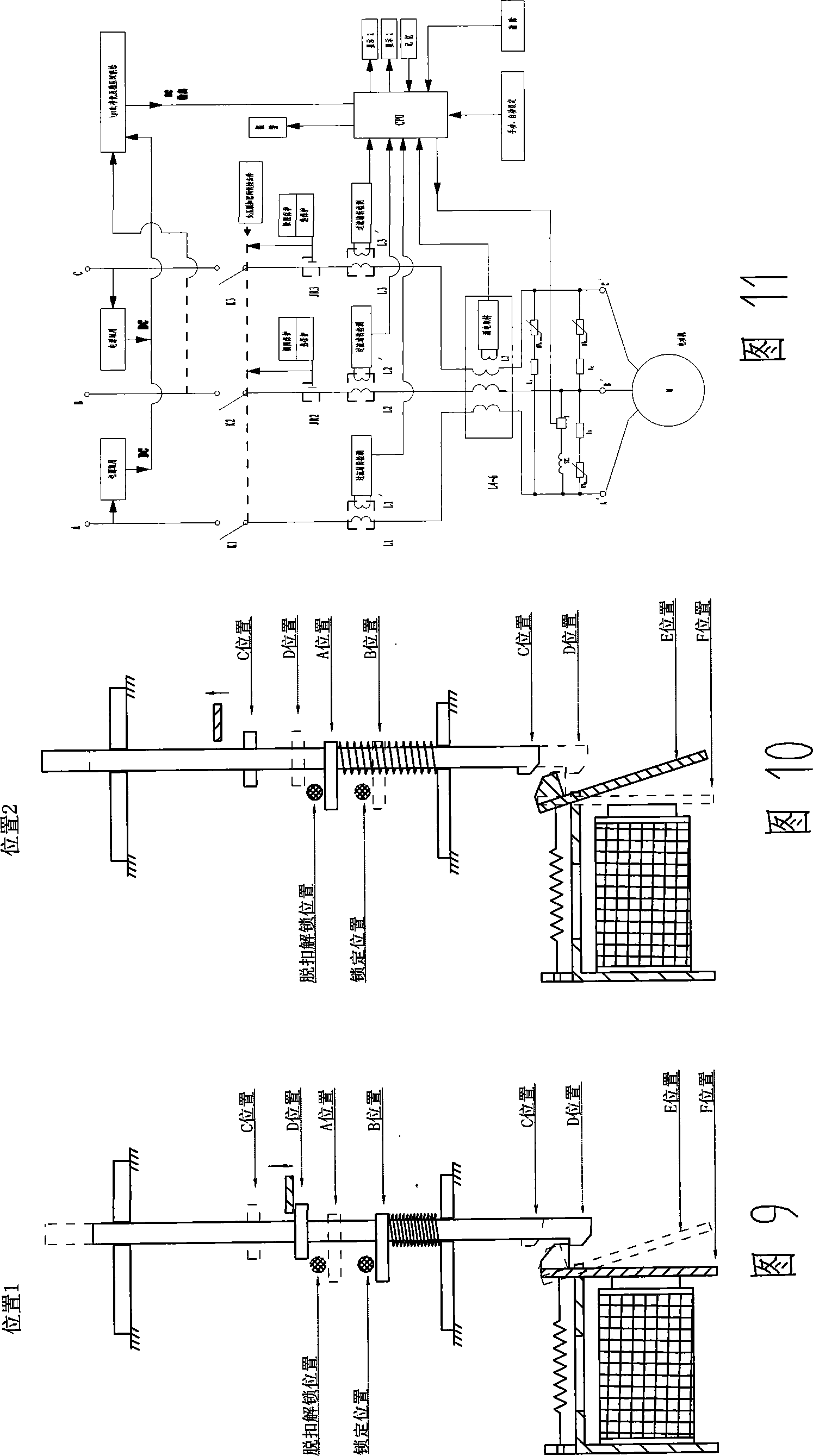

[0056] As shown in Figure 1, Figure 2, Figure 3, Figure 4, Figure 5, Figure 6, a plastic shell type mechatronics three-phase AC motor protector with energy storage impact device, including a casing 1, installed in the machine The upper part of the shell 1 A, B, C three-phase power supply wiring 2, the breaker movable contact 3, the breaker lever 5 installed in the middle of the case 1, the circuit breaker trip lever 6, the overcurrent protection element 7, installed in The lower wiring 9 of the three-phase power transmission to the motor at the lower part of the casing 1 is characterized in that it also includes a delayer 20, a voltage loss release 30, an energy storage impact device 40, a current detection transformer 10, and a zero sequence current transformer 8; also includes a central processing unit (CPU) and related protection circuits, displays, alarms, and recorders; the delay device 20 is installed in the middle of a phase slot of the casing 1 through the upper bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com