Inter-connecting structure between multi-layer base board and producing method

A multi-layer substrate and substrate technology, which is applied in the structural connection of printed circuits, semiconductor/solid-state device manufacturing, printed circuit components, etc., can solve problems such as limited rigid system packaging concepts, and achieve the effect of improving packaging density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

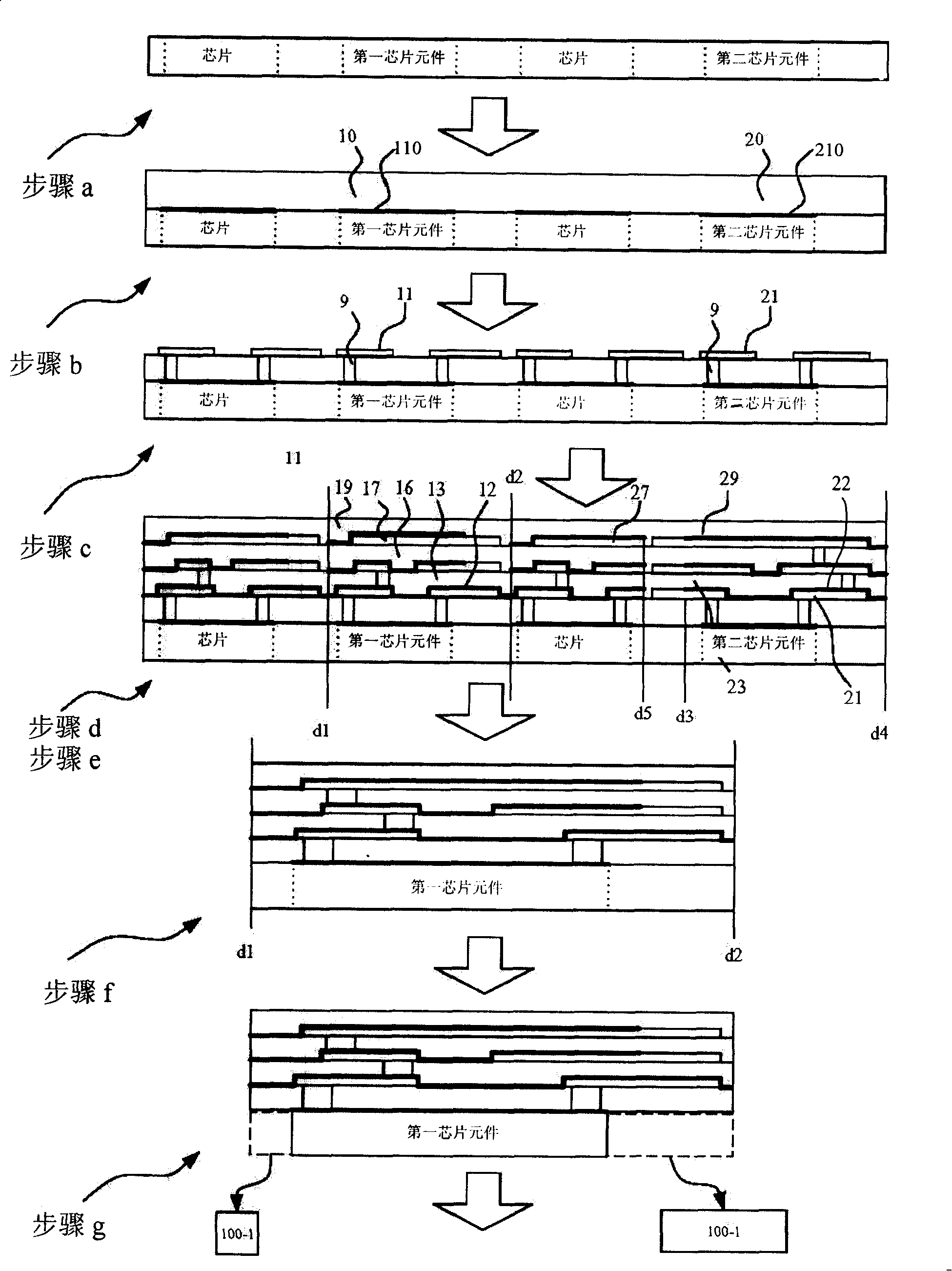

[0025] Relevant detailed description and technical contents of the present invention are as follows now in conjunction with the accompanying drawings:

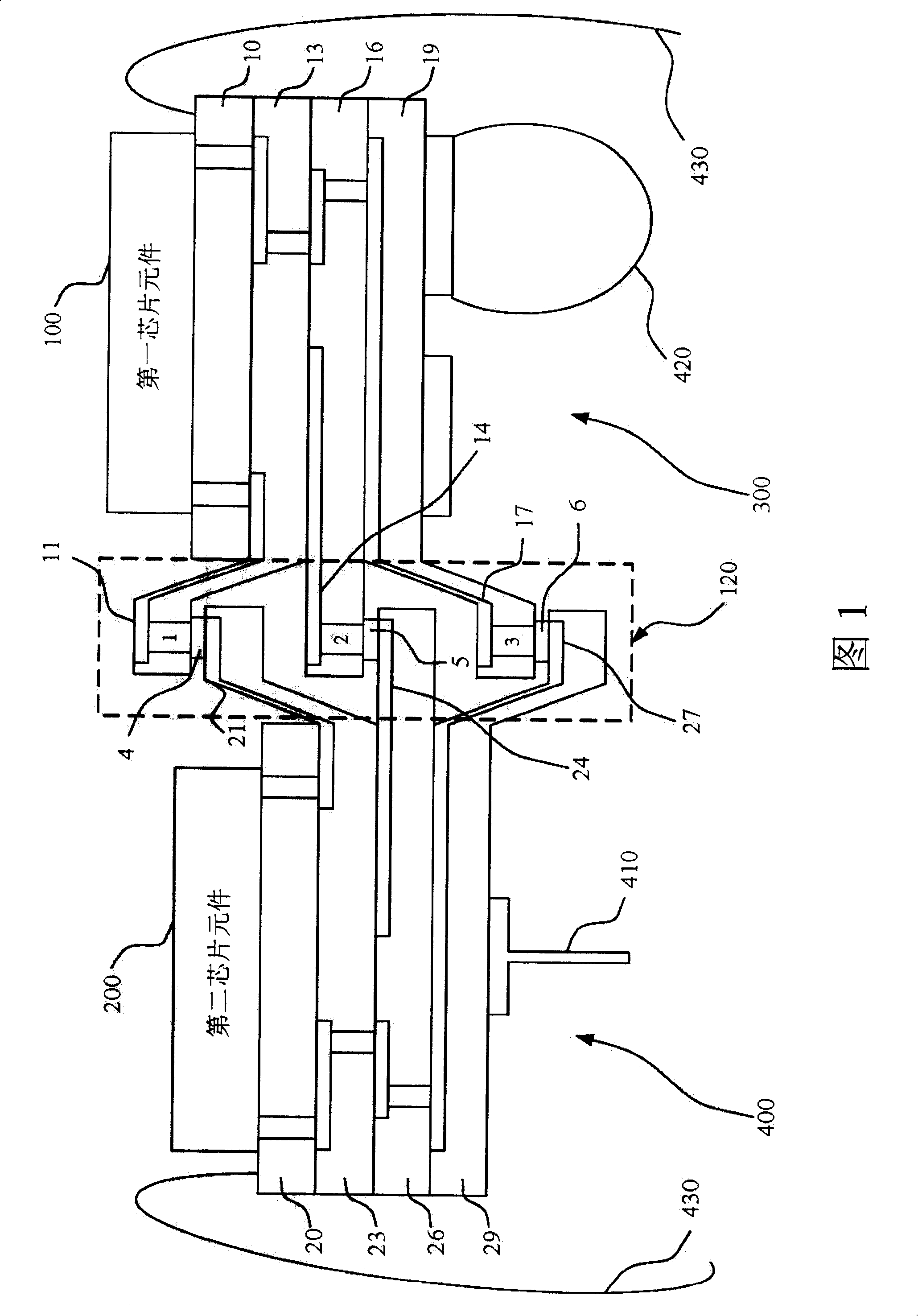

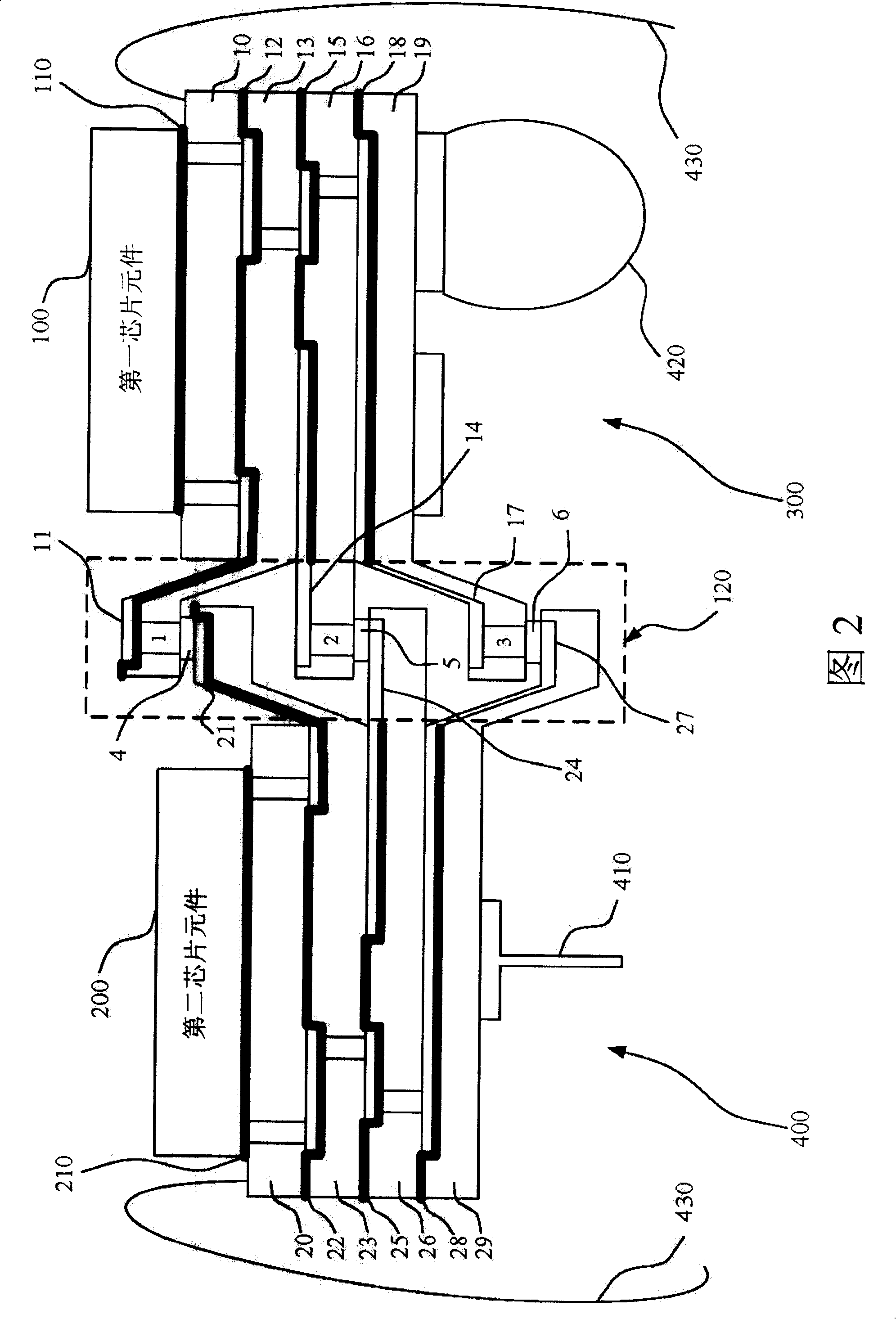

[0026] Please refer to FIG. 1 , which is a cross-sectional view of an interconnection structure between multilayer substrates according to an embodiment of the present invention. The interconnection structure between multilayer substrates at least includes a first multilayer substrate 300 , a second multilayer substrate 400 and a plurality of via holes 1 , 2 and 3 formed on the first multilayer substrate 300 . The first outer surface of the first multilayer substrate 300 is connected to a first chip component 100 , and the first outer surface of the second multilayer substrate 400 is connected to a second chip component 200 . The first chip component 100 and the second chip component 200 may be any type of chip components such as logic components, memory components, analog components, optoelectronic components, micro-electrome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com