Integrated SiCr metal thin film resistors for SiGe RF-BiCMOS technology

A technology of metal thin film resistors and thin film resistors, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as the limitation of thin film resistance values, achieve the effects of reducing parasitic effects and increasing packaging density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

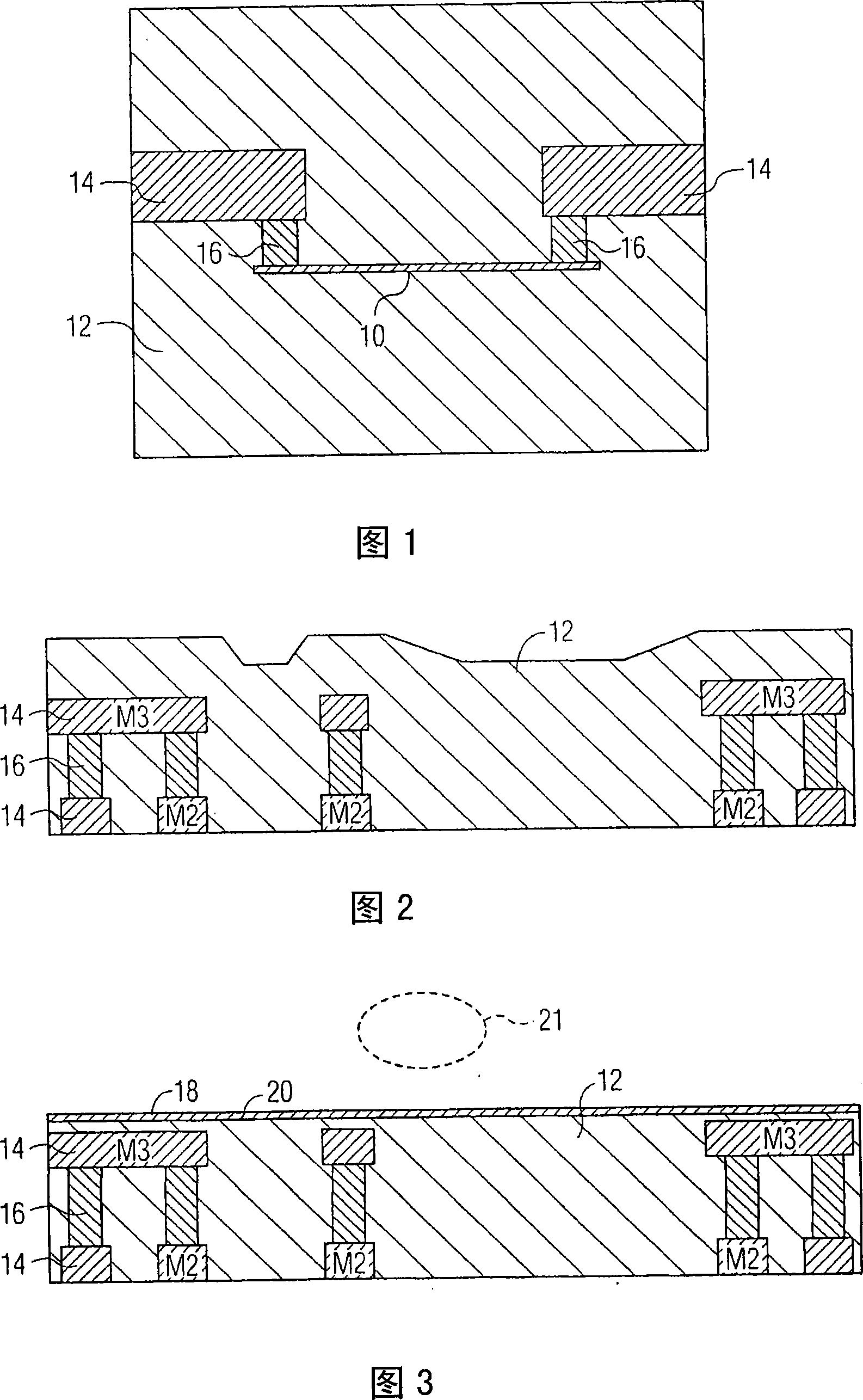

[0021] Referring to FIG. 1 , there is shown a SEM (scanning electron microscope) cross-sectional view of a SiCr metal thin film resistor 10 produced according to an embodiment of the present invention. For example, in silicon dioxide (SiO 2 ) form a SiCr thin film resistor 10 on a high-density planarized dielectric substrate 12 . SiCr thin film resistor 10 is directly connected to upper metal level 14 via via 16 .

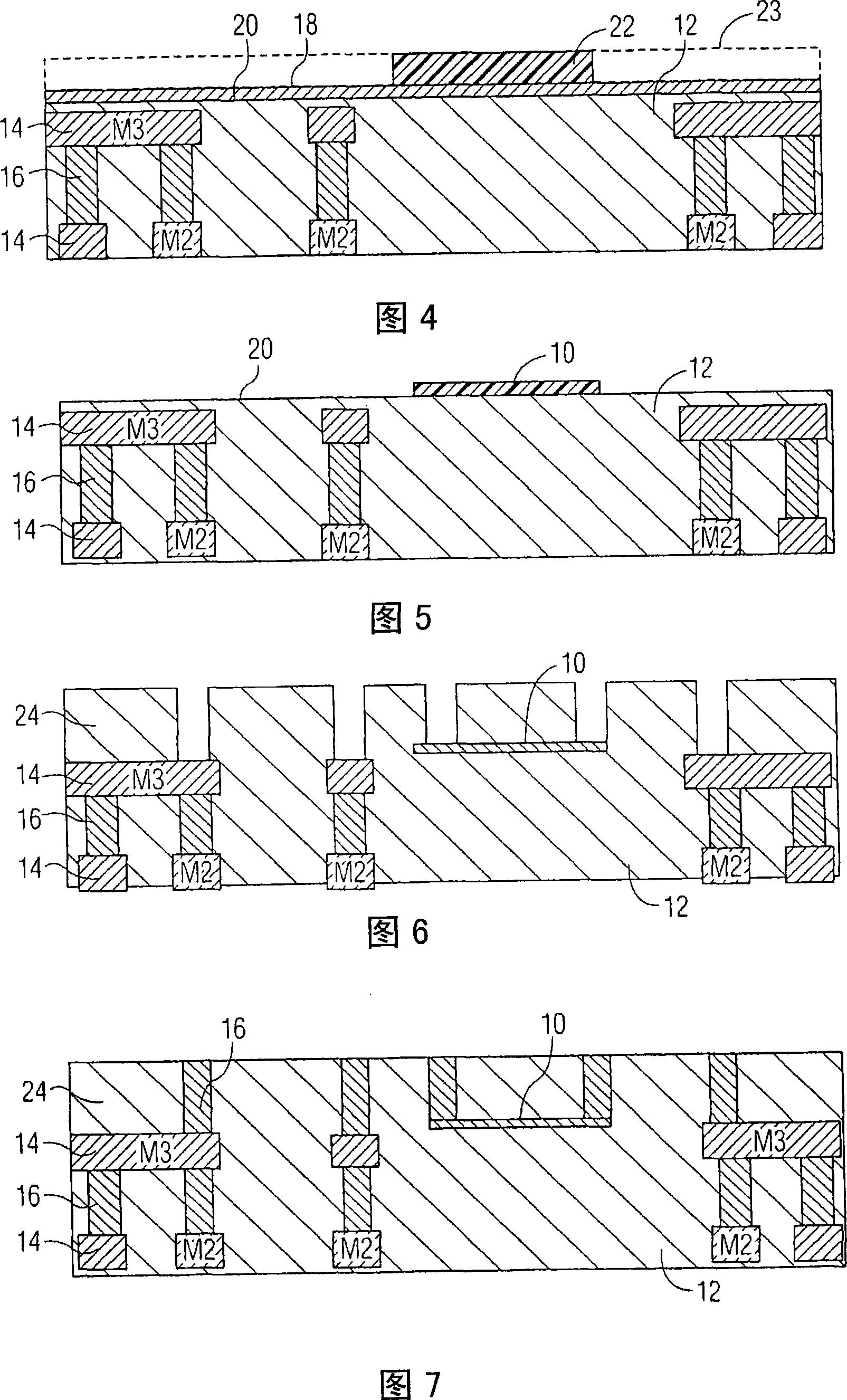

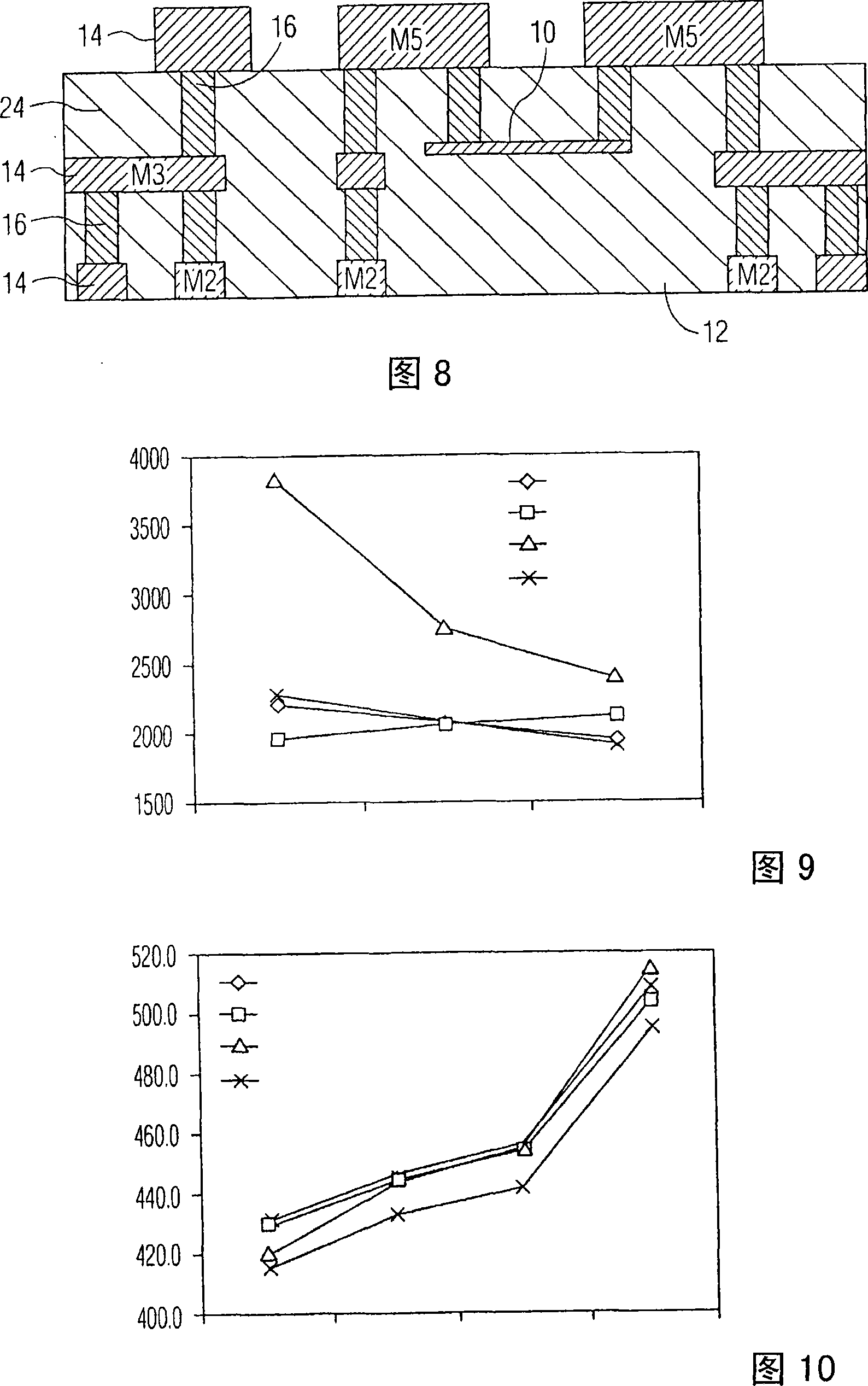

[0022] Referring to FIGS. 2 to 8 , a method for forming a SiCr thin film resistor 10 according to an embodiment of the present invention is shown.

[0023] In FIG. 2 , a high density dielectric substrate 12 is shown comprising a plurality of metal layers 14 (eg, M2 , M3 ) interconnected by vias 16 . Metal layer 14 and vias 16 are formed using conventional photolithographic techniques. For example, dielectric substrate 12 may be formed using a high density plasma (HDP) chemical vapor deposition (CVD) process. For example, other suitable techniques including plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com