Method for increasing effective thermal conductivity coefficient of float glass batch

A float glass and thermal conductivity technology, applied in glass production and other directions, can solve the problems of low melting efficiency of radiation heat exchange surface, affecting the increase of glass liquid temperature, and ineffective heat transfer, so as to promote circulation and increase heating rate. , the effect of improving the bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

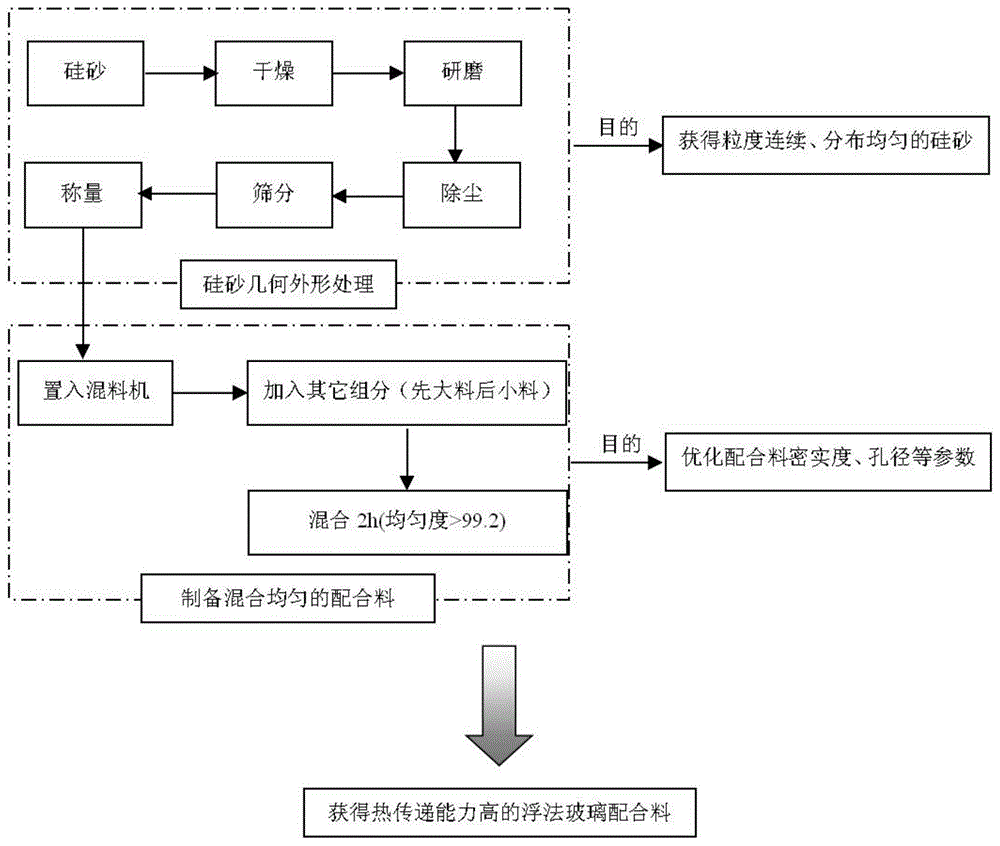

[0023] The method for improving the thermal conductivity of the batch of float glass comprises the steps of:

[0024] 1) Put 200g of dried silica sand into a 1L grinding tank of a single-head ball mill, set the design speed at 450rmp, and set the grinding time at 1h to grind the silica sand to control the geometric shape and particle size of the silica sand particles ;

[0025] 2) Clean and dry the ground silica sand granules, then select a 160-mesh standard sieve to sieve the dedusted silica sand, and then use a 200-mesh standard sieve to remove the silica sand with a smaller particle size to ensure the uniformity of the silica sand particle size sex and continuity;

[0026] 3) According to the production scale, product variety and quality requirements of float glass, design the composition of float glass batch materials, and accurately weigh the homogenized and dust-removed silica sand and other raw materials;

[0027] 4) Pour the accurately weighed raw materials into the ...

Embodiment 2

[0030] The method for improving the thermal conductivity of the batch of float glass comprises the steps of:

[0031] 1) Put 200g of dried silica sand into a 1L grinding tank of a single-head ball mill, set the design speed at 450rmp, and set the grinding time at 2h to grind the silica sand to control the geometric shape and particle size of the silica sand particles ;

[0032] 2) Clean and dry the ground silica sand granules, then select a 200-mesh standard sieve to sieve the dedusted silica sand, and then use a 230-mesh standard sieve to remove the silica sand with a smaller particle size to ensure the uniformity of the silica sand particle size sex and continuity;

[0033] 3) According to the production scale, product variety and quality requirements of float glass, design the composition of float glass batch materials, and accurately weigh the homogenized and dust-removed silica sand and other raw materials;

[0034] 4) Pour the accurately weighed raw materials into the ...

Embodiment 3

[0037] The method for improving the thermal conductivity of the batch of float glass comprises the steps of:

[0038] 1) Put 200g of dried silica sand into a 1L grinding tank of a single-head ball mill, set the design speed at 450rmp, and set the grinding time at 3h, and grind the silica sand to control the geometric shape and particle size of the silica sand particles ;

[0039] 2) Clean and dry the ground silica sand granules, then select a 400-mesh standard sieve to sieve the dedusted silica sand, and then use a 460-mesh standard sieve to remove the silica sand with a smaller particle size to ensure the uniformity of the silica sand particle size sex and continuity;

[0040] 3) According to the production scale, product variety and quality requirements of float glass, design the composition of float glass batch materials, and accurately weigh the homogenized and dust-removed silica sand and other raw materials;

[0041] 4) Pour the accurately weighed raw materials into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal diffusivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com