Integrated COBLED (Chip on Board Light-emitting Diode) encapsulation structure

A technology of integrated packaging and installation grooves, applied in the field of lighting, can solve the problems of poor light-emitting effect, poor air-tightness, and poor heat-dissipation effect, so as to improve LED life and stability, improve light-emitting rate, and ensure air-tightness and physical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

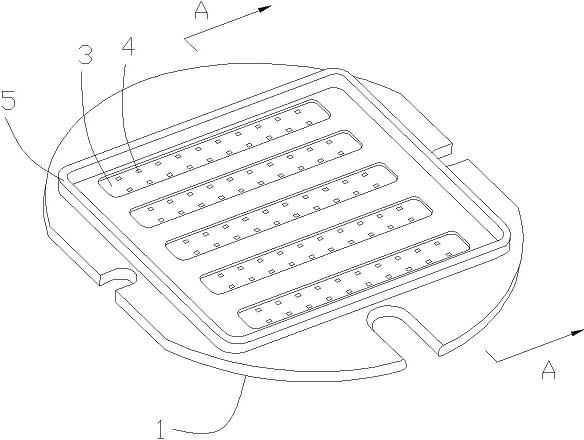

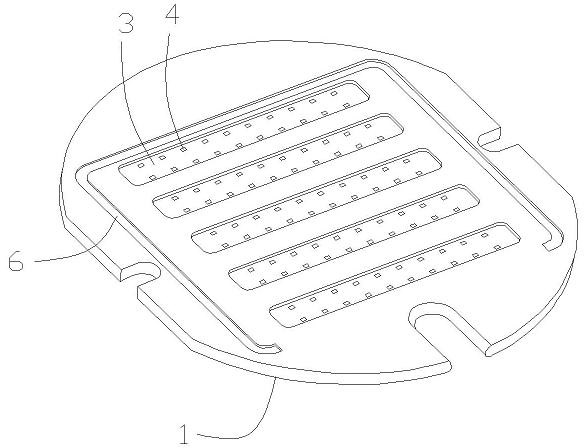

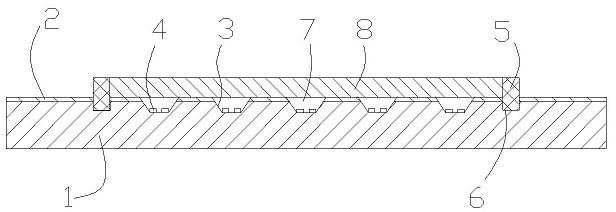

[0017] In this embodiment, a COBLED integrated packaging structure, such as figure 1 with image 3 As shown, it includes a substrate 1 and a circuit layer 2 arranged on the surface of the substrate. The substrate is an aluminum substrate, and five strip-shaped grooves 3 arranged in parallel are arranged on the substrate. In this embodiment, the light-emitting chip 4 emits blue light. Chips, the light-emitting chips are evenly arranged at the bottom of the strip groove 3, and the light-emitting chips are connected to the circuit layer 2 on the substrate by wire bonding, such as image 3 As shown, the side wall of the bar-shaped groove is inclined, forming a structure of a reflector. Such as figure 2 As shown, an installation groove 6 is arranged on the periphery of the strip groove, the installation groove surrounds the strip groove on three sides, and a circle of wall glue 5 is also arranged on the periphery of the strip groove, the wall glue surrounds the strip groove, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com