Hydraulic gyration tailstock

A tailstock and hydraulic technology, applied in the direction of tailstock/top, turning equipment, toolholder accessories, etc., can solve the problems of low work efficiency and labor, and achieve the effect of compact structure, high degree of automation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

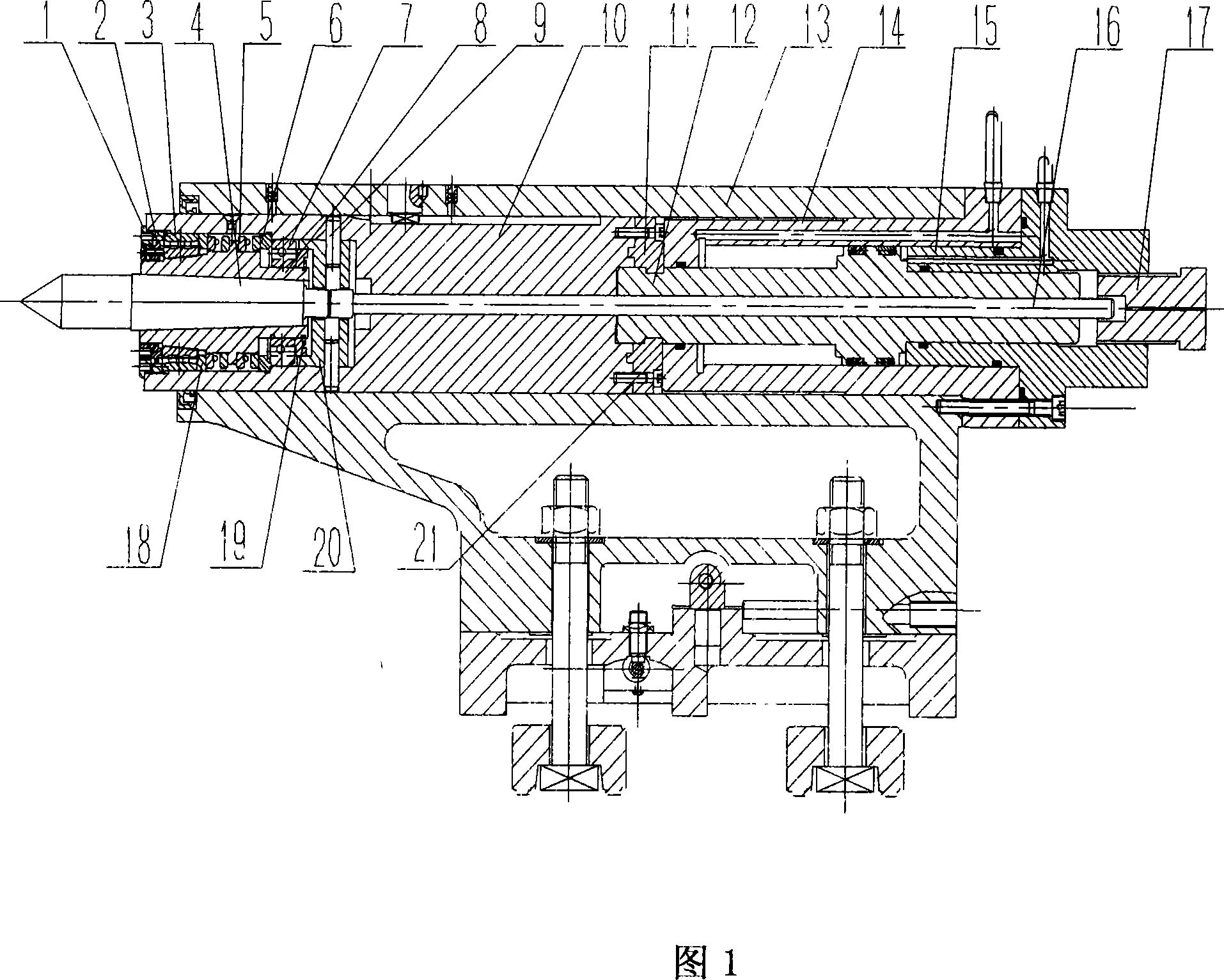

[0017] As shown in FIG. 1 , the present invention includes two oil chambers 14 , 15 of the piston cylinder designed on the rear end surface of the tailstock body 13 . Hydraulic pressure is used to drive the piston shaft 12 to move forward and backward. The piston shaft 12 is connected with the tailstock main shaft 10 through the fixing ring 11 and the screw 21, and the tailstock main shaft 10 and the piston shaft 12 move synchronously to realize the hydraulic automatic telescopic movement of the tailstock main shaft 10.

[0018] A tailstock sleeve supported by bearings is installed in the front hole of the tailstock main shaft to realize the rotatable performance of the tailstock sleeve. The specific structure is: the internal thread at the front end of the tailstock main shaft 10 is connected with the nut 1, and the right end surface of the nut 1 is close to the double row 3 outer rings of cylindrical roller bearings, 3 outer rings of double-row cylindrical roller bearings ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com