Method for revising wafer transferring device of milling equipment

A technology of transmission device and calibration method, which is applied in the direction of grinding device, grinding/polishing equipment, grinding machine tool, etc., can solve the problems of large aiming error, inconvenient observation, and inaccurateness, and achieve easy observation, improved alignment accuracy, and accurate The effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

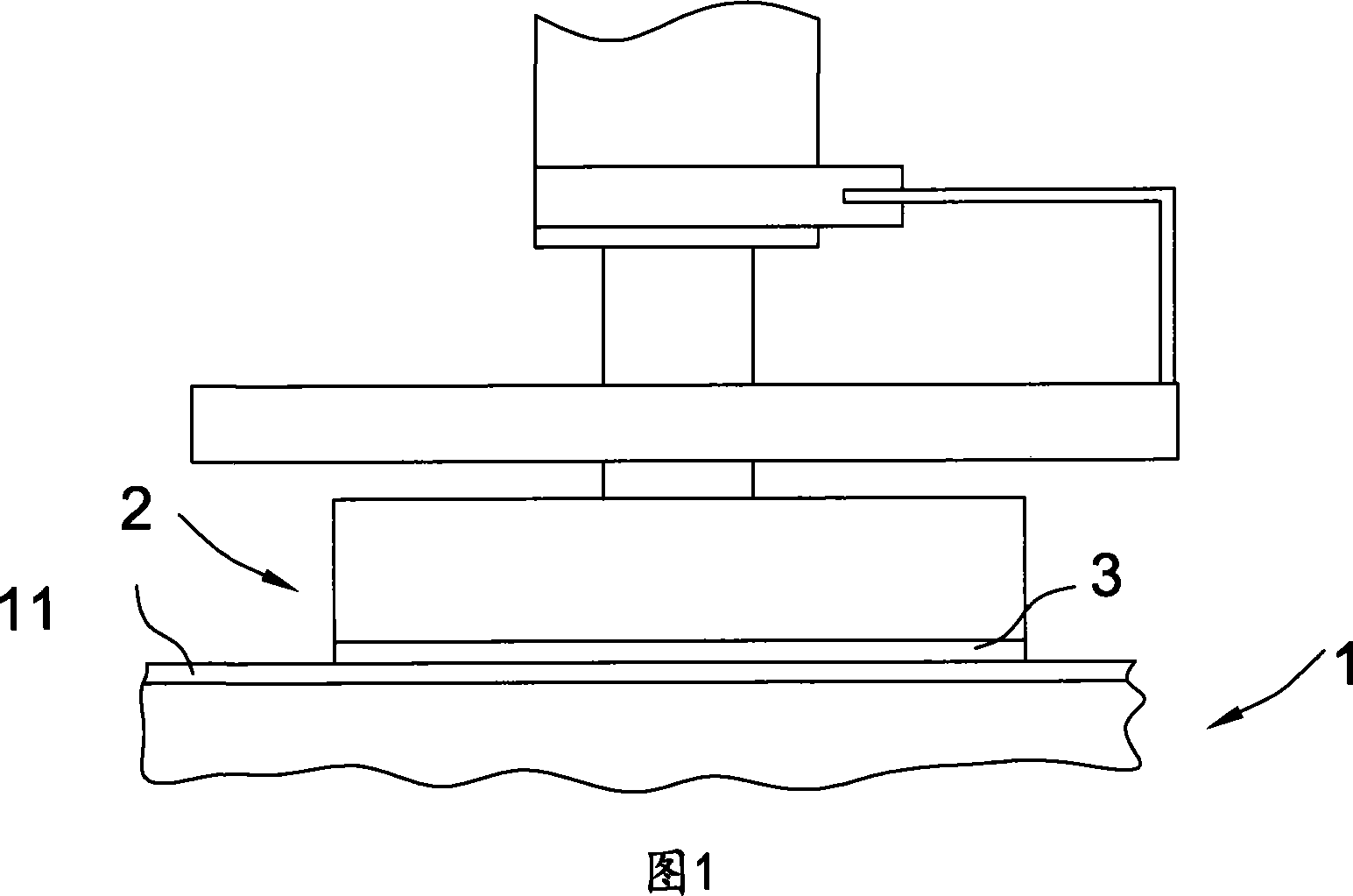

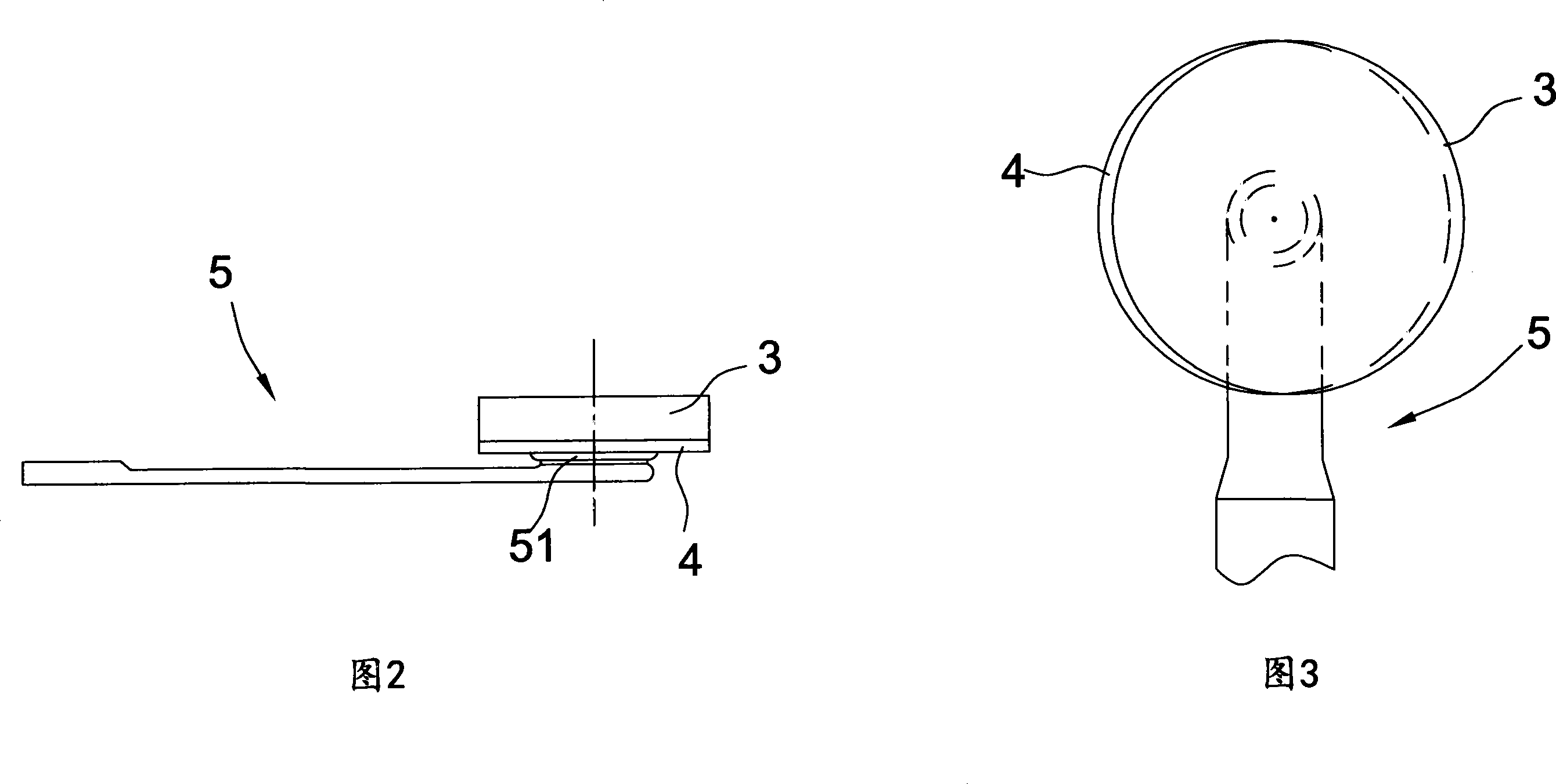

[0021] Referring to accompanying drawings 2 to 3, a method for calibrating a wafer conveying device of a grinding equipment is used to periodically verify the pick-up position of the conveying device of a chemical-mechanical grinder. The conveying device described here usually refers to It is a manipulator, and the front end of the manipulator has a vacuum nozzle for absorbing wafers (the left side is "rear" in the accompanying drawing 2, and the right side is "front").

[0022] The calibration method of the wafer transfer device of the grinding equipment includes the following steps:

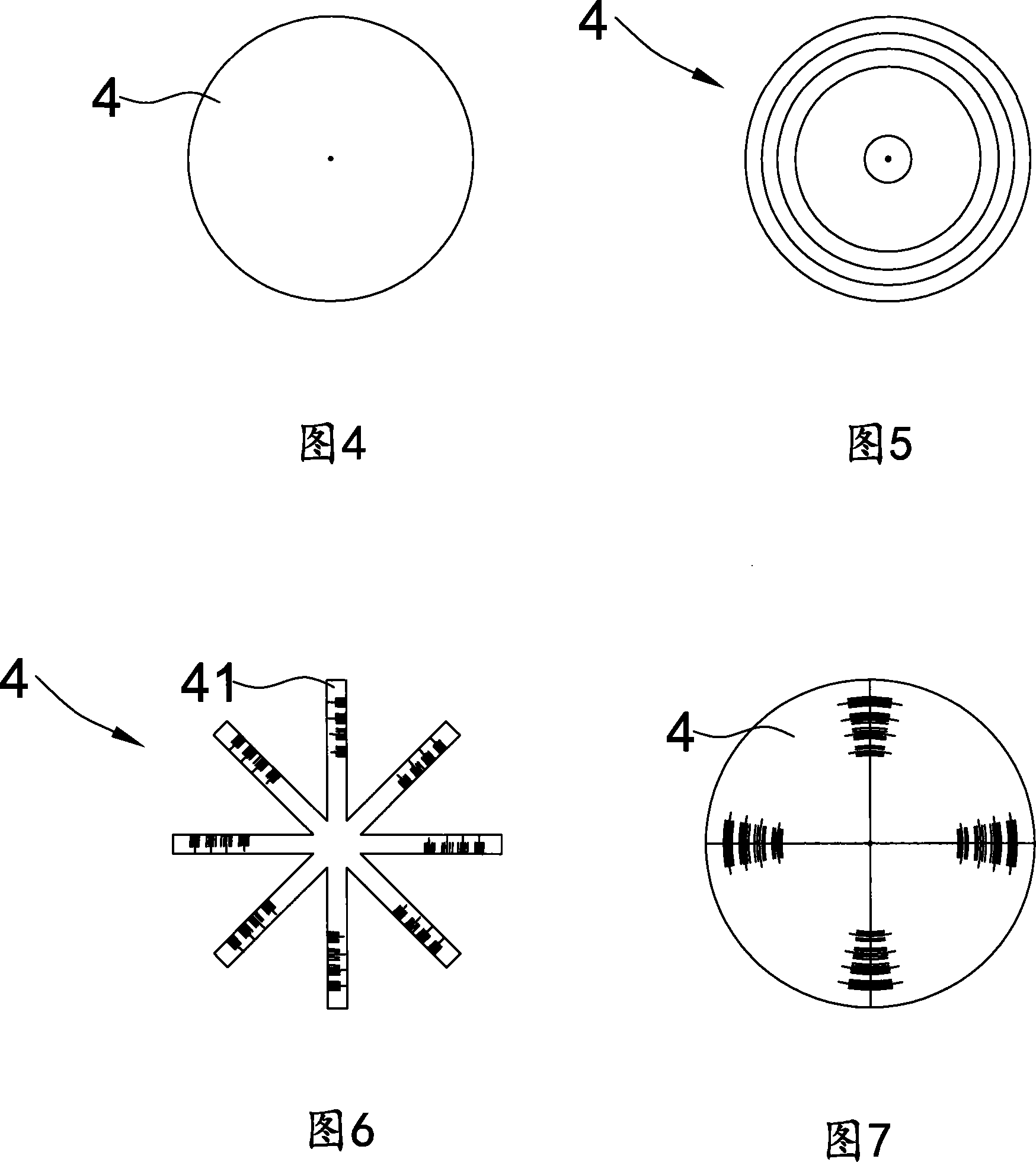

[0023] a, the correction sheet 4 whose outer diameter is greater than or equal to the outer diameter of the wafer 3 to be processed is set on the transfer device 5, the front end of the transfer device 5 has a support part 51 for carrying the wafer, and the support part 51 has a vacuum suction mouth, align the center of the correction sheet 4 with the center of the support part 51, and fix the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com