Method for using aerated plastics to manufacture doubling plate ship

A foamed plastic, double-layer board technology, applied in applications, household components, household appliances, etc., can solve the problems of high maintenance costs, large steel consumption, and high navigation danger, and achieve convenient maintenance, extended service life, and improved The effect of the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

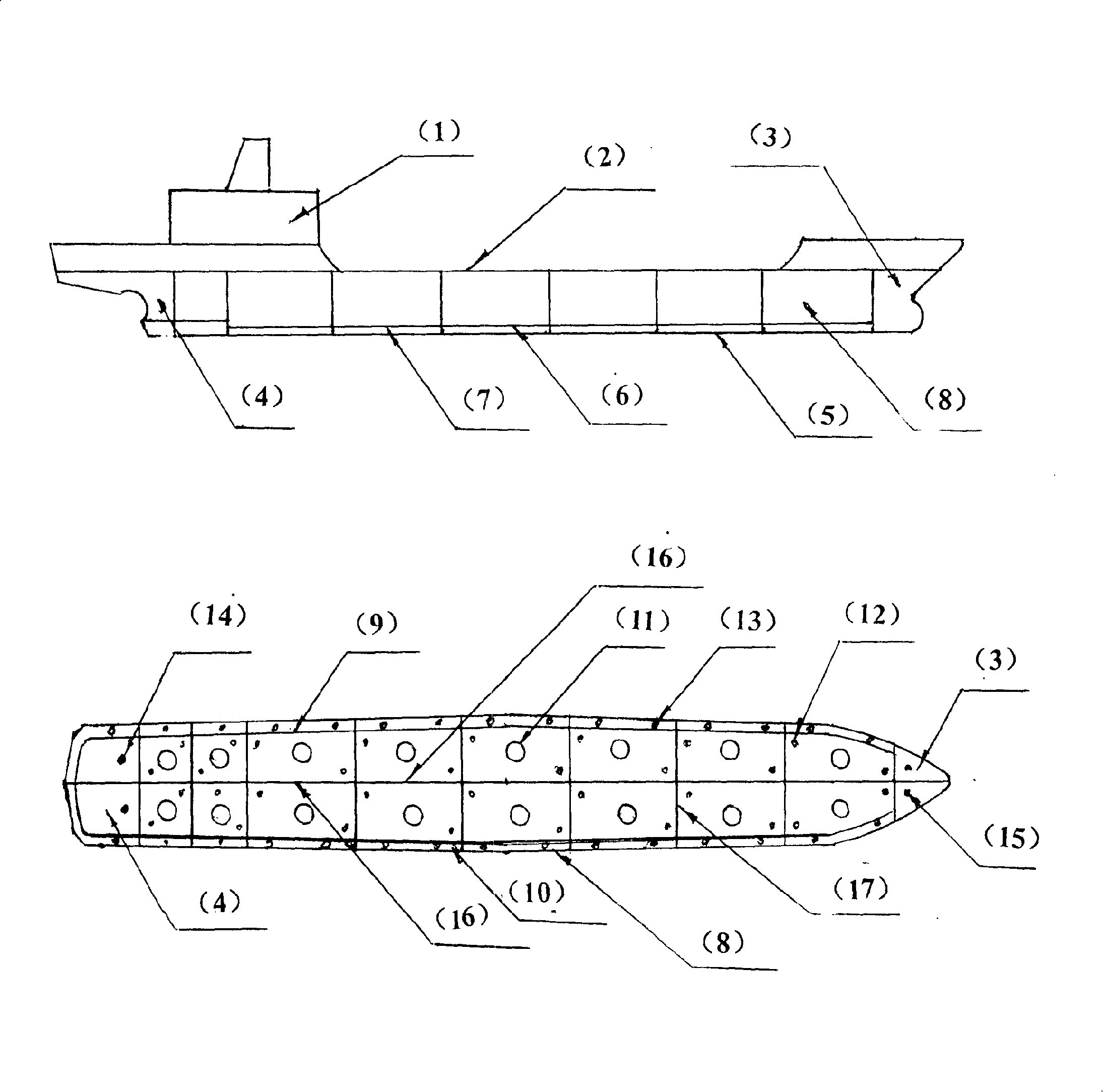

[0047] A method for manufacturing a double-layer ship using foamed plastics, comprising the steps of:

[0048] 1. According to the quality requirements, the specifications of domestically produced expandable polystyrene F151 or F251 are matured into pre-expanded polystyrene particles at a density of 15-30 kg / m3; or made into particle foam according to the required density; Or make mature granular bubbles with plastic materials of other varieties.

[0049] 2. After the steel plate structure between the outer plate and the inner plate of the ship (1) is derusted by sandblasting, paint the adhesive, use asphalt 5# plus 30% gasoline or use 2127 phenolic glue, and put it on the outer plate and the inner plate. Brushing on steel plate structural plates such as mid-bottom longitudinal truss girder (16), main floor plate (17), reinforcing plate in the space.

[0050] 3, the pre-expanded polystyrene granule of slaking, all fills the slaking granule bubble in the hole of bow deck (15) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com