Holding device for screw energy-saving lamp tube formation

A clamping device and energy-saving lamp technology, which is applied in glass forming, glass reshaping, manufacturing of ships or leading wires, etc. It can solve the problems of poor consistency of glass tubes, affecting the pass rate and quality of glass tubes, and poor working conditions, etc. problem, to achieve the effect of good air tightness, simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of the present invention will be described below:

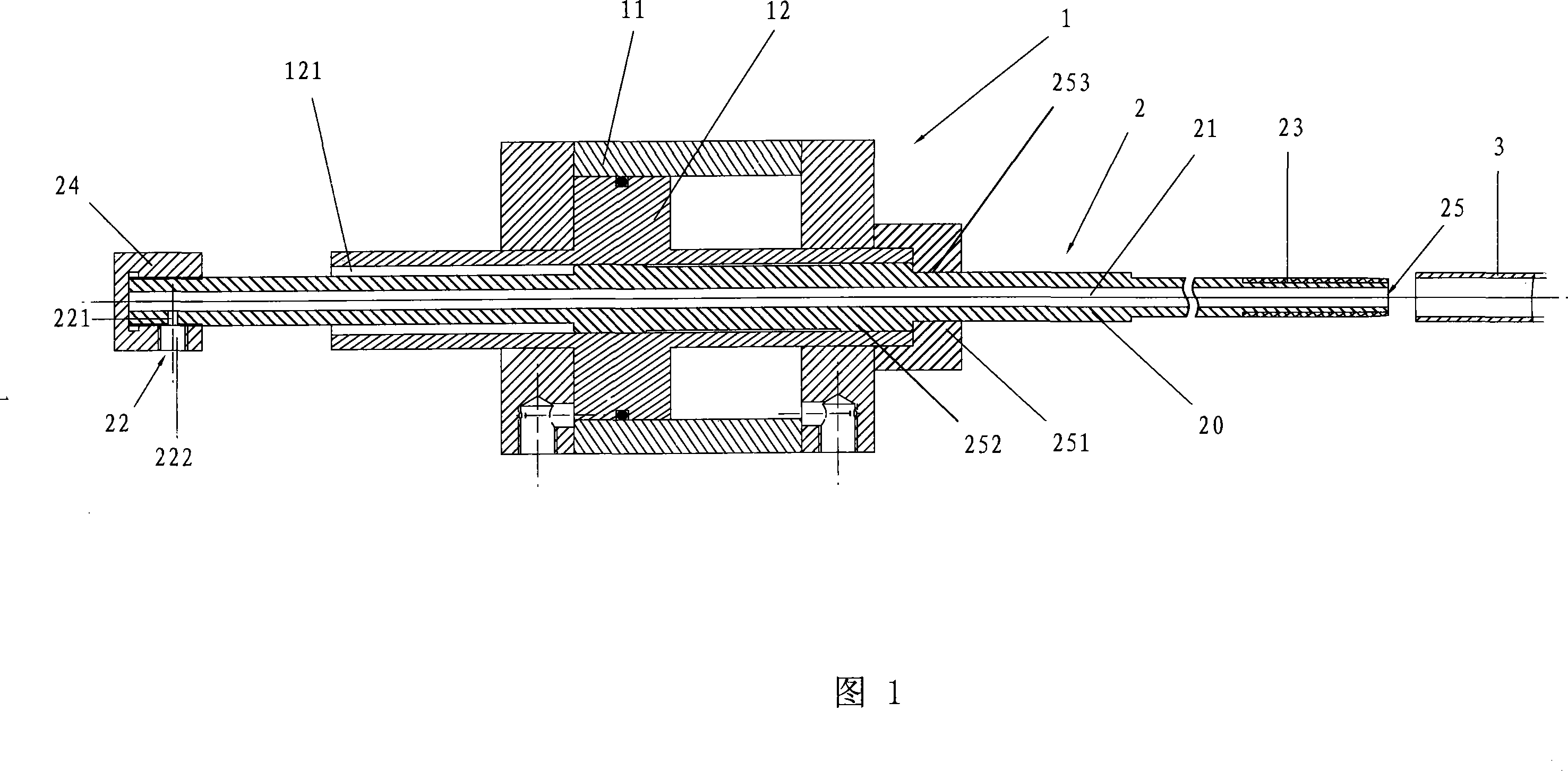

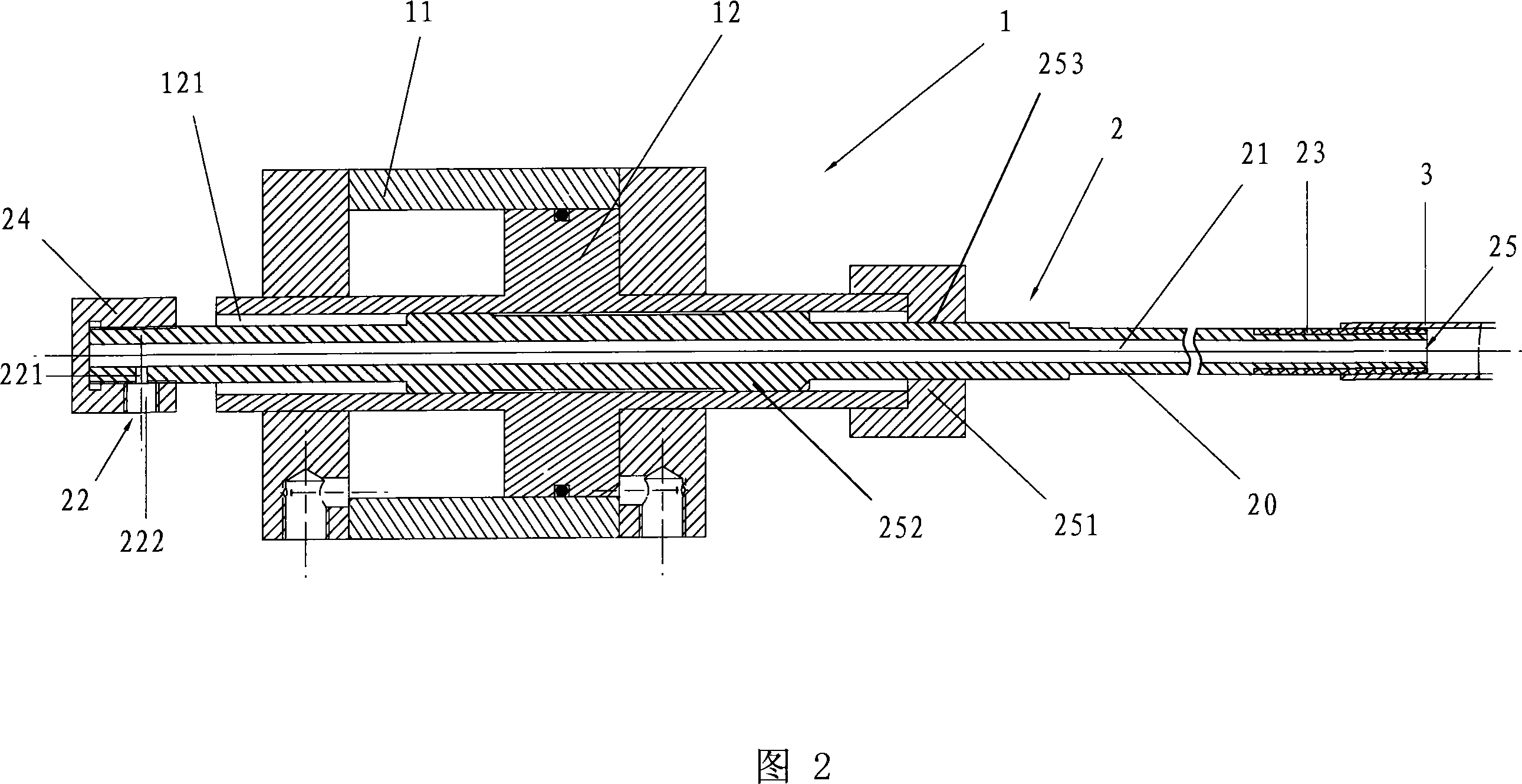

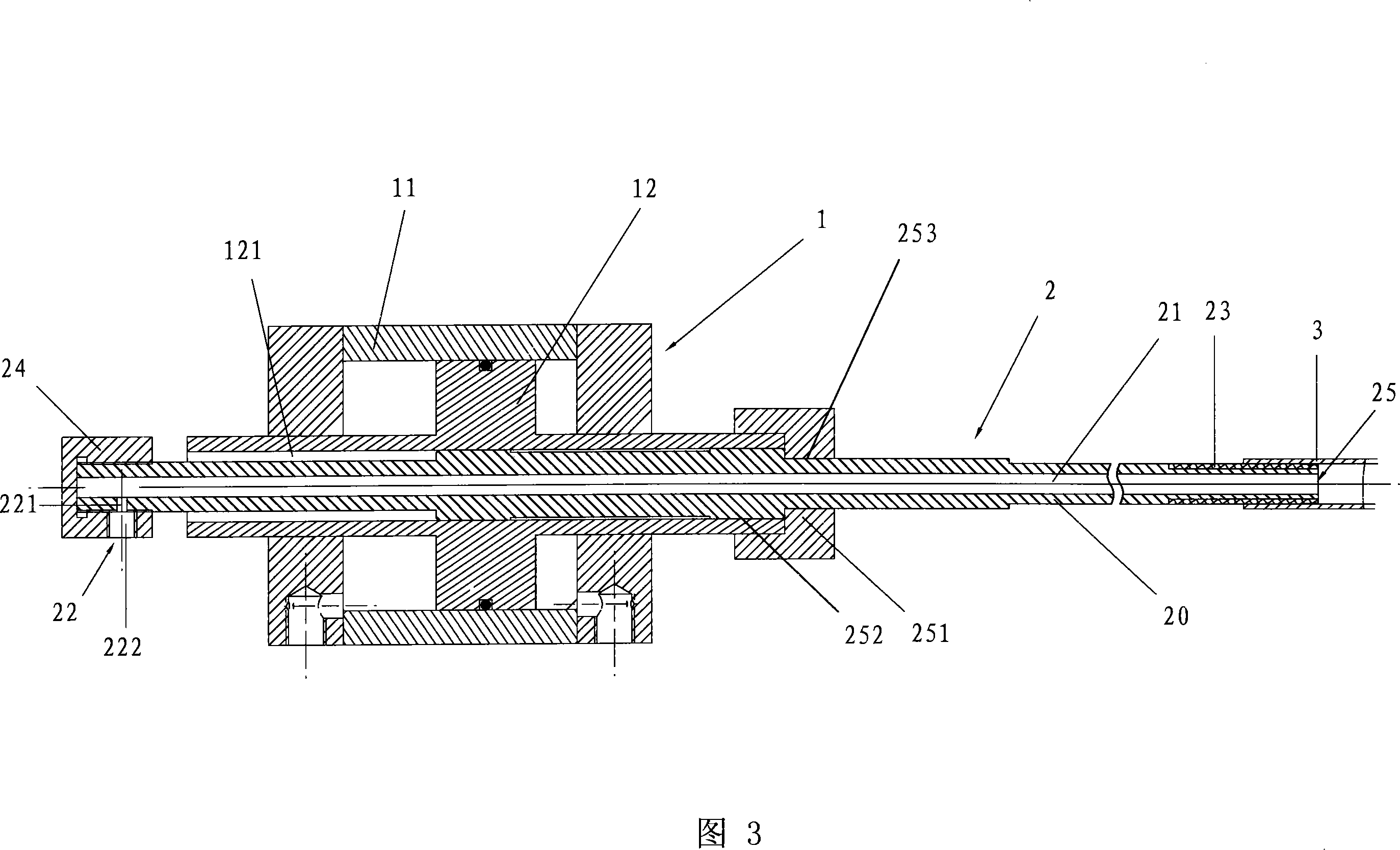

[0016] As shown in FIGS. 1, 2, and 3, the clamping device for forming the spiral energy-saving lamp tube 3 according to the present invention includes a cylinder 1 having a cylinder 11 and a piston rod 12, and a movable rod 2.

[0017] Among them, cylinder 1 is a modified standard thin cylinder. A through hole 121 is opened in the middle of the piston rod 12 along the axial direction, and the movable rod 2 is slidably arranged in the through hole 121.

[0018] The movable rod 2 includes a cylindrical rod body 20 with an air hole 21 along the axial direction. The air hole 21 is an opening 25 at the front end of the rod body 20, and the tail part is also communicated with the outside.

[0019] A ring-shaped rubber sleeve 23 is sleeved on the front end of the movable rod 2. The outer surface of the rubber sleeve is slightly tapered, and the shape of the outer surface is consistent with the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com