Method for increasing combination strength of plasma spraying ceramic coat and substrate

A technology of ceramic coating and bonding strength, which is applied in coating, metal material coating process, fusion spraying, etc., and can solve the problems of reducing the service life of the coating, the effect is small, and the bonding strength of the coating and the substrate is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

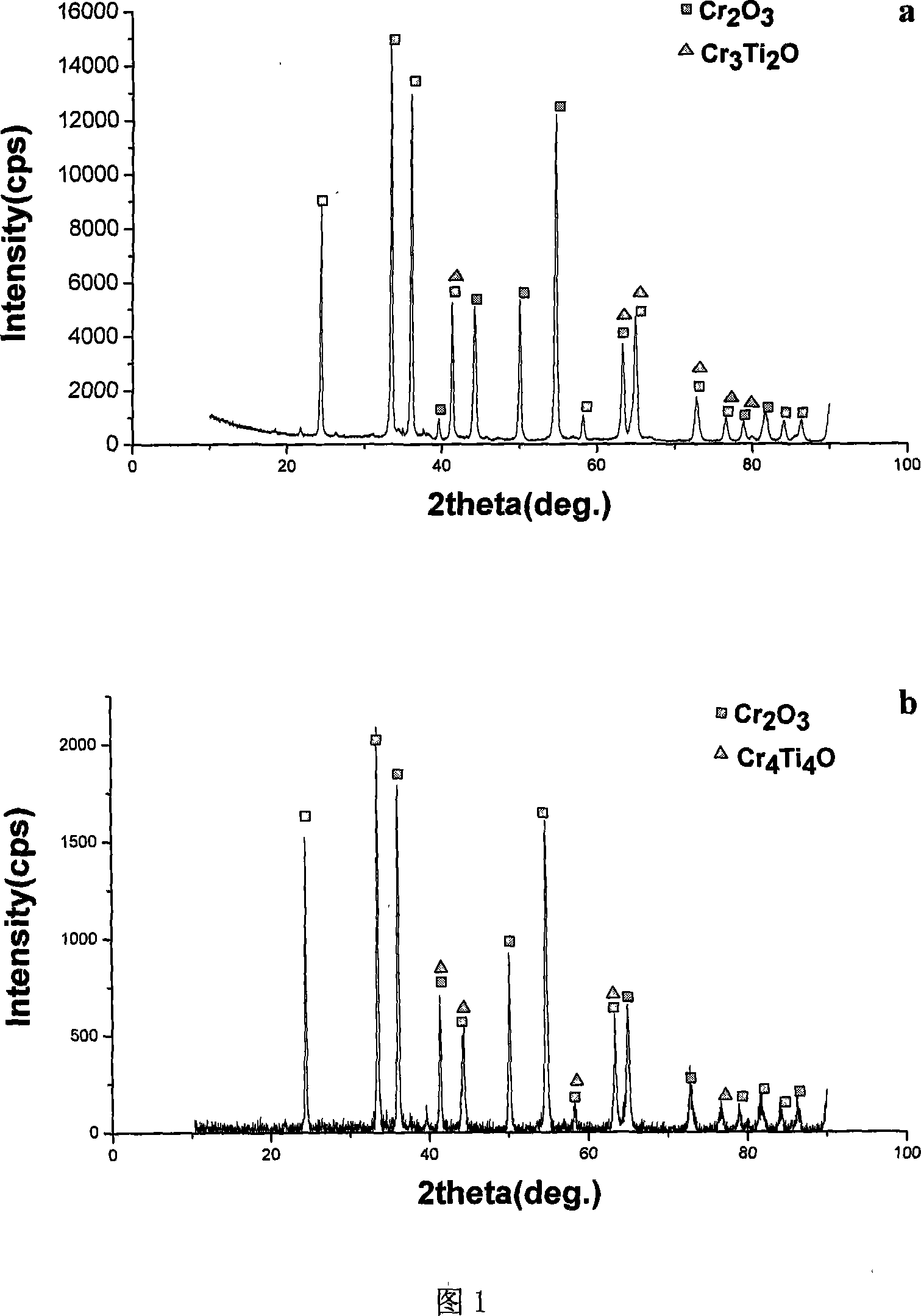

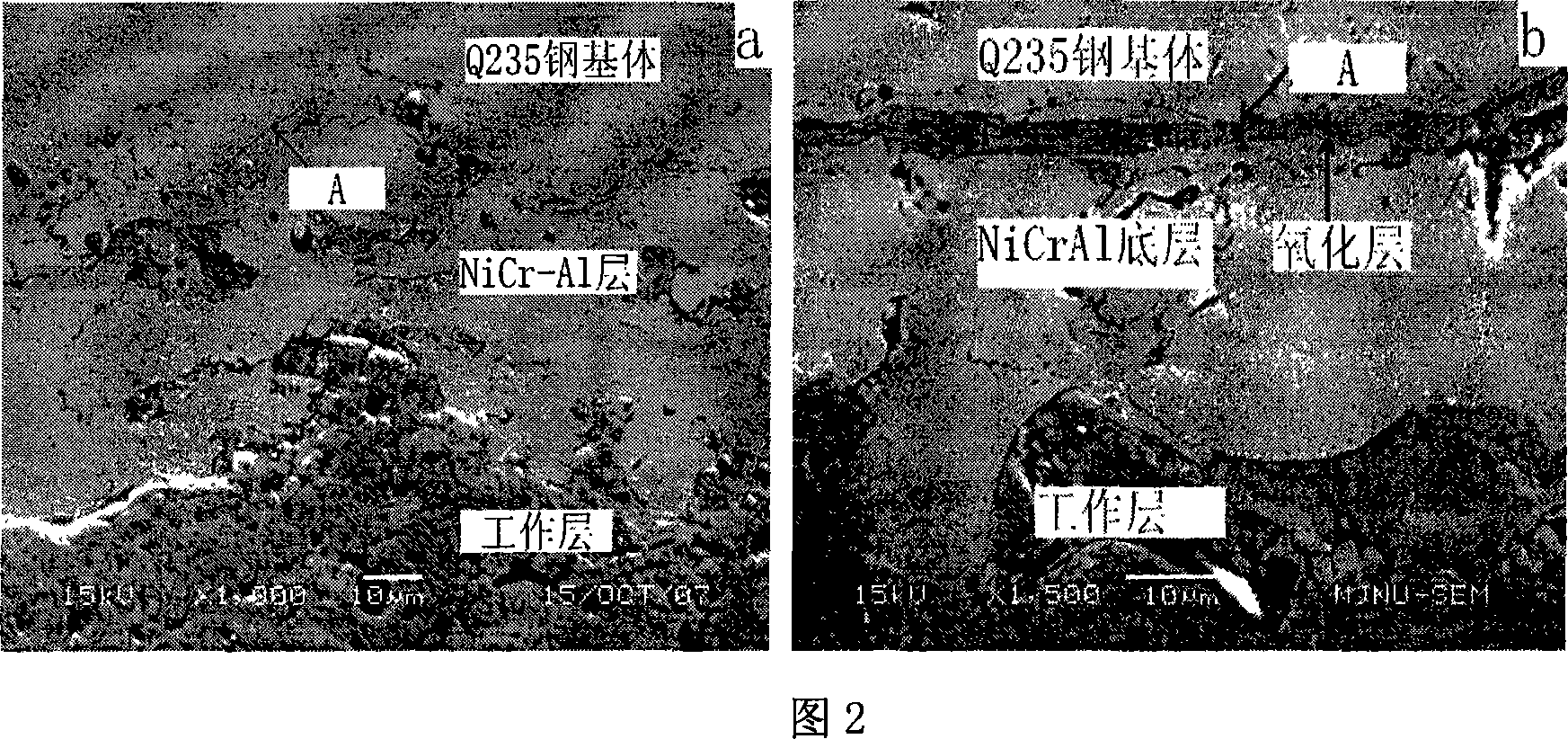

[0028] (1) Spray the NiCrAl bottom layer on the surface of the carbon steel substrate by plasma spraying method, and then use Cr 2 o 3 -8%TiO 2 Spraying the ceramic coating of the working layer;

[0029] (2) Put the above-mentioned sprayed carbon steel substrate into a furnace at 400° C. for 8 hours, and then cool with the furnace.

Embodiment 2

[0031] (1) Spray the NiCr bottom layer on the surface of the carbon steel substrate by plasma spraying method, and then use Al 2 o 3 -13%TiO 2 Spraying the ceramic coating of the working layer;

[0032] (2) Put the above-mentioned sprayed carbon steel substrate into a furnace at 450° C. for 6 hours, and then cool with the furnace.

Embodiment 3

[0034] (1) Spray the NiCrAl bottom layer on the surface of the carbon steel substrate by plasma spraying method, and then use ZrO 2 -8%Y 2 o 3 Spraying the ceramic coating of the working layer;

[0035] (2) Put the above-mentioned sprayed carbon steel substrate into a furnace at 450° C. for 4 hours, and then cool with the furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com