Thin film curtain wall structure

A film and curtain wall technology, applied in the field of external maintenance structures, can solve the problems of complex installation process, poor appearance effect, difficult waterproofing, etc., and achieve the effect of good waterproof function, convenient adjustment and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

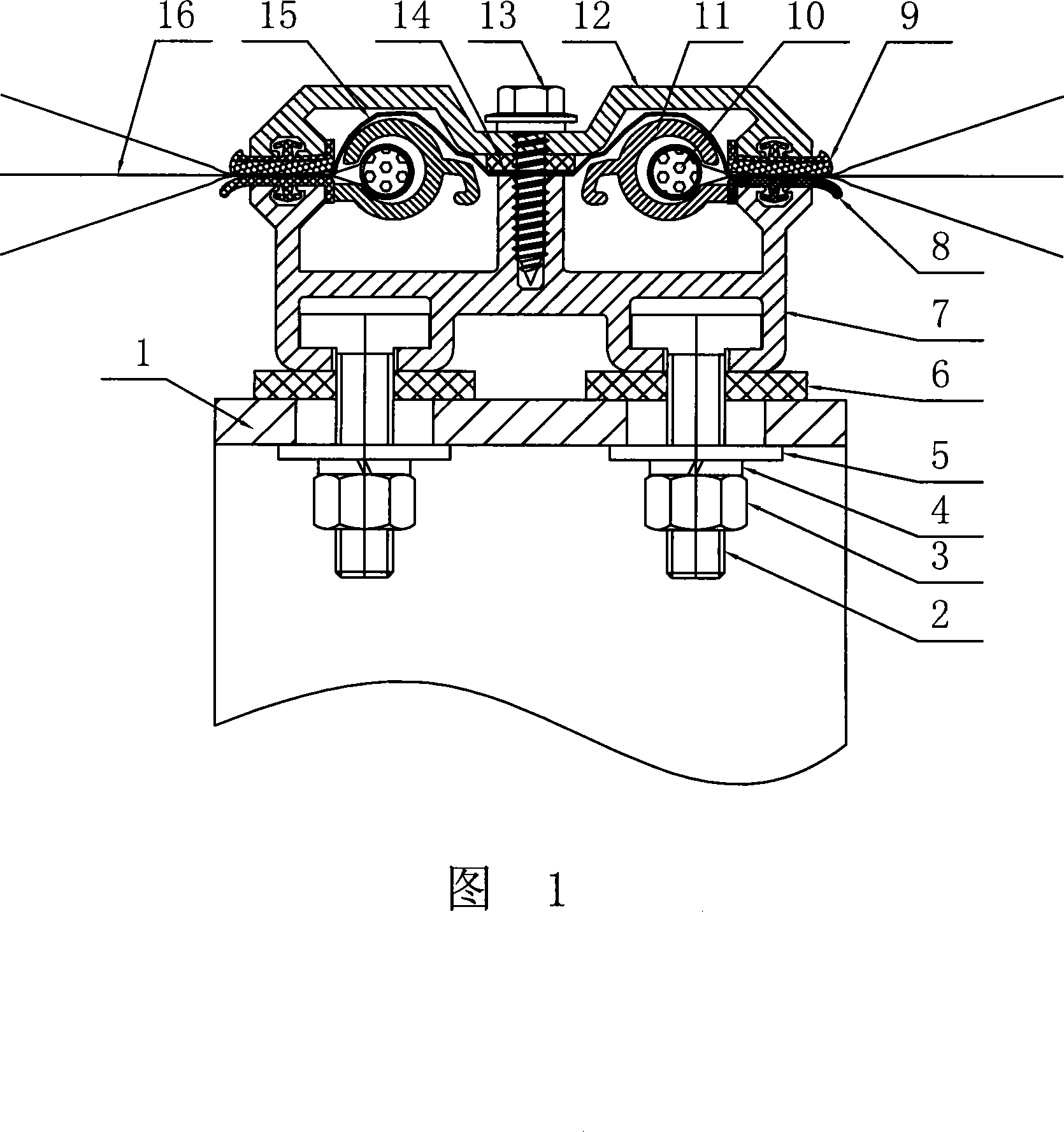

[0019] The present invention will be described in further detail below in conjunction with FIG. 1 . The film curtain wall structure includes a film 16, a pulling cable 10 fixed around the film 16, and clips for fixing the film 16 on the main building components. Wherein the film 16 can adopt a single-layer structure, multi-layer structure or air cushion structure, and the traction rope 10 can adopt various slender rods, fiber ropes or steel wire ropes and the like. The clamping piece can be composed of a metal profile keel 7 with a special groove for bolts and a special groove for rubber strips, and a metal profile gland 12 assembled on the bottom surface above the metal profile keel 7 with a dedicated rubber strip groove symmetrical to the metal profile keel 7 , the metal profile clamp 11 and other parts clamping and fixing the traction cable 10 on the periphery of the film 16 are combined. The specification, shape and size of each component in the clamping piece shall be de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com