High precision six-axis laser measurement device and measurement method

A laser measurement, high-precision technology, used in measurement devices, optical devices, instruments, etc., can solve the problems of measurement accuracy interference, complex optical path layout, and limitations of the versatility of measurement devices, achieving strong versatility, high measurement accuracy, Small error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The measuring device and measuring method of the present invention are described in detail below in conjunction with the accompanying drawings of the description:

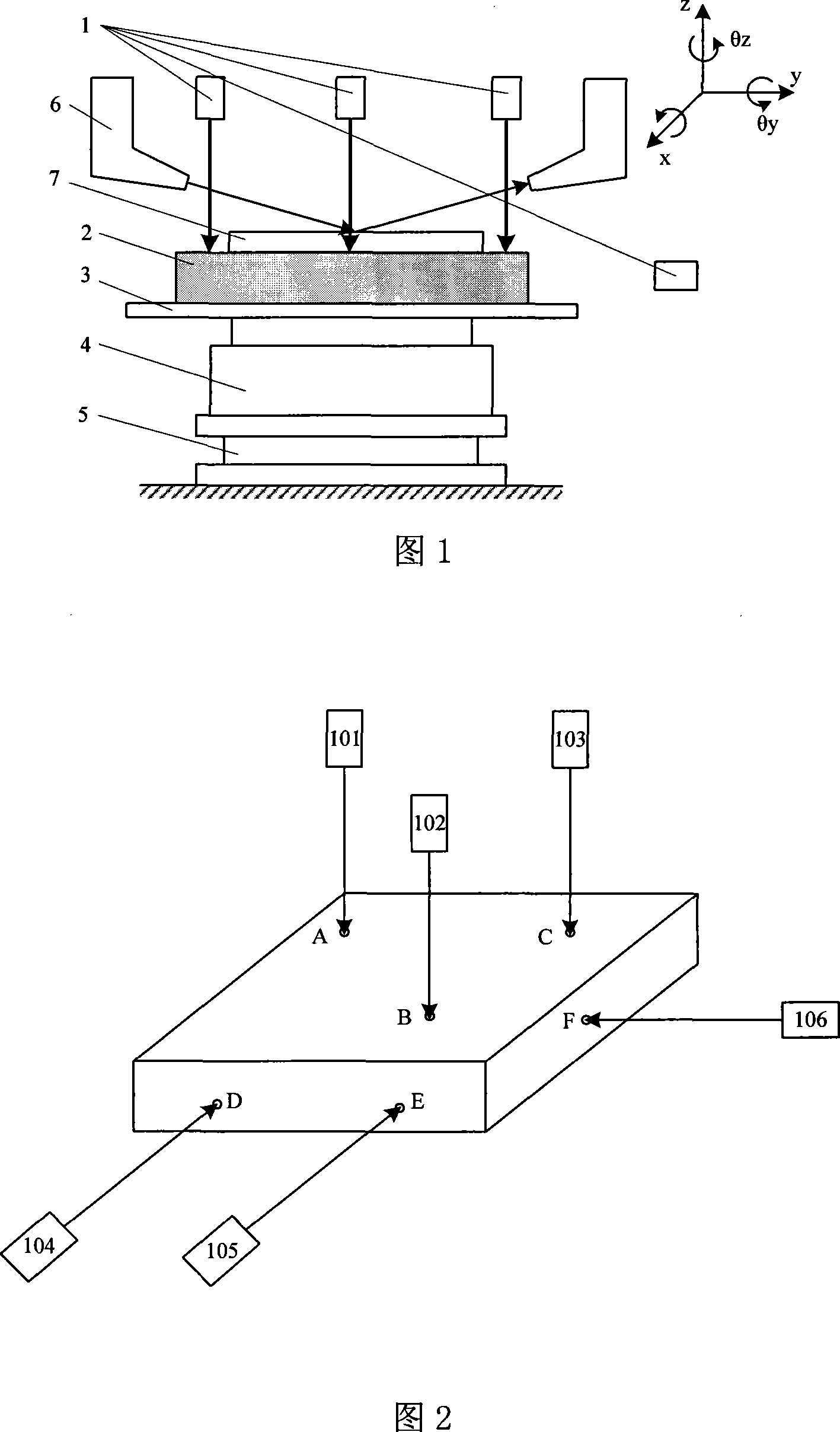

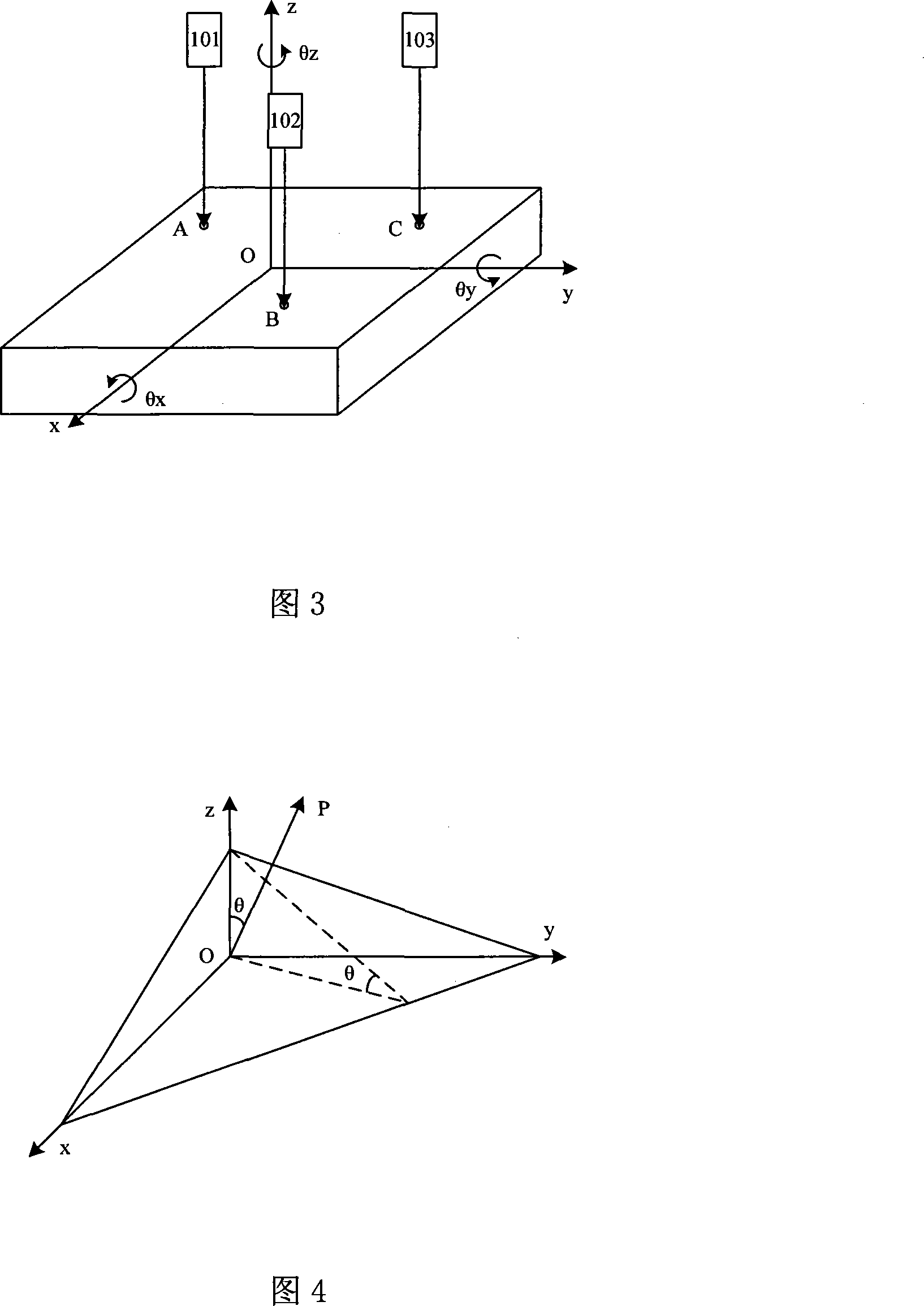

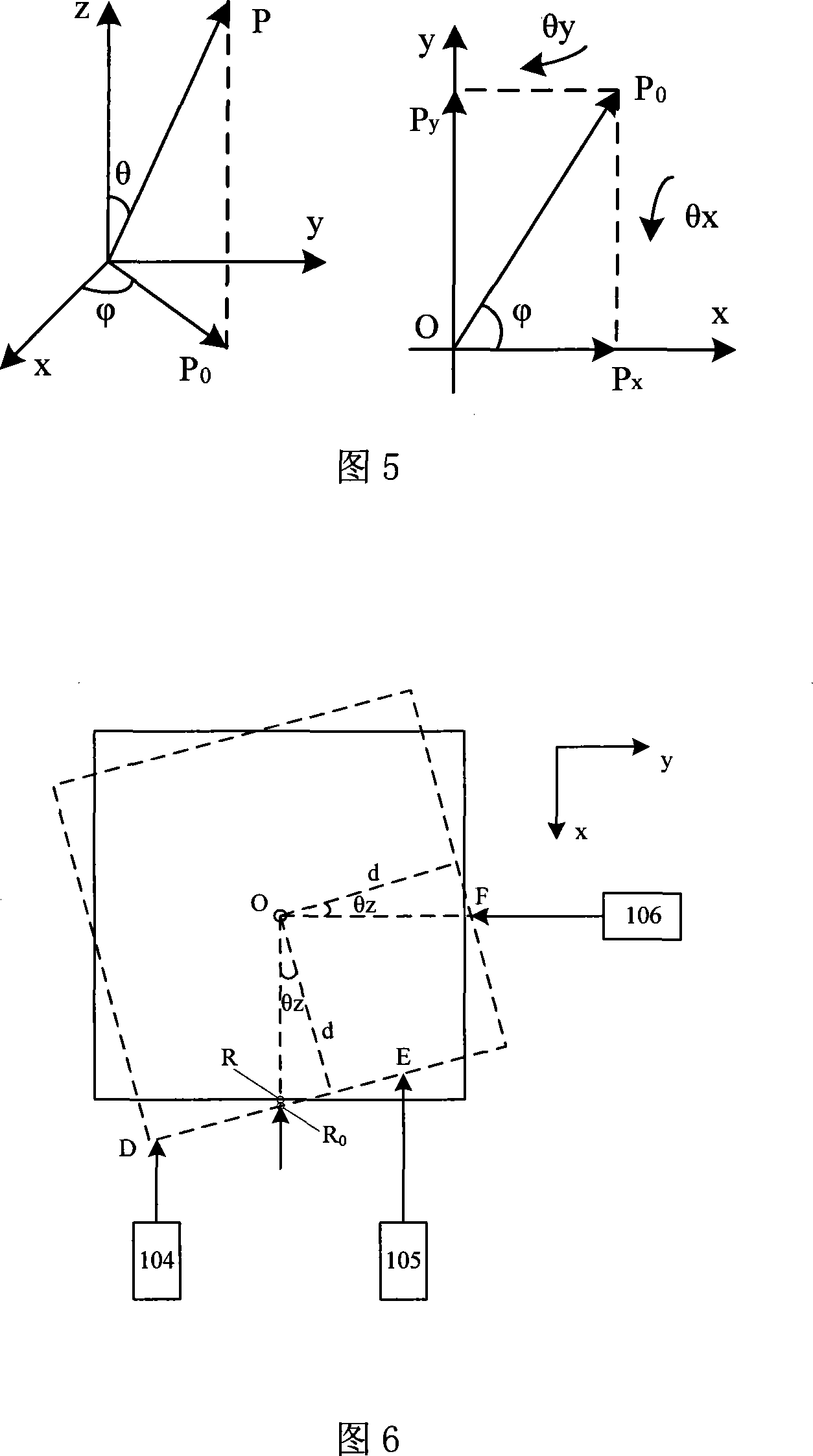

[0025] A specific embodiment of the present invention, device structure as shown in Figure 1, wherein comprises laser interferometry system (1), workbench (2) and motion execution system, motion execution system consists of vertical motion actuator (4) and horizontal The motion actuator (5) is composed. The laser interferometry system consists of three single-axis laser interferometers arranged vertically and three single-axis laser interferometers arranged horizontally. Workbench (2) is an optical device with relatively high surface smoothness and smoothness. It is made of micro-fine glass. The upper surface and adjacent sides are polished and coated. It can be used as the measurement surface of the laser interferometer, as shown in the figure 7. Gas rings (201) with different diameters are arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com