Film pole distance multi-pole natural-circulating electrolytic tank with ion film

An ionic membrane electrolyzer, bipolar technology, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of voltage drop and affect the voltage of the cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation will be described in detail below in conjunction with the accompanying drawings.

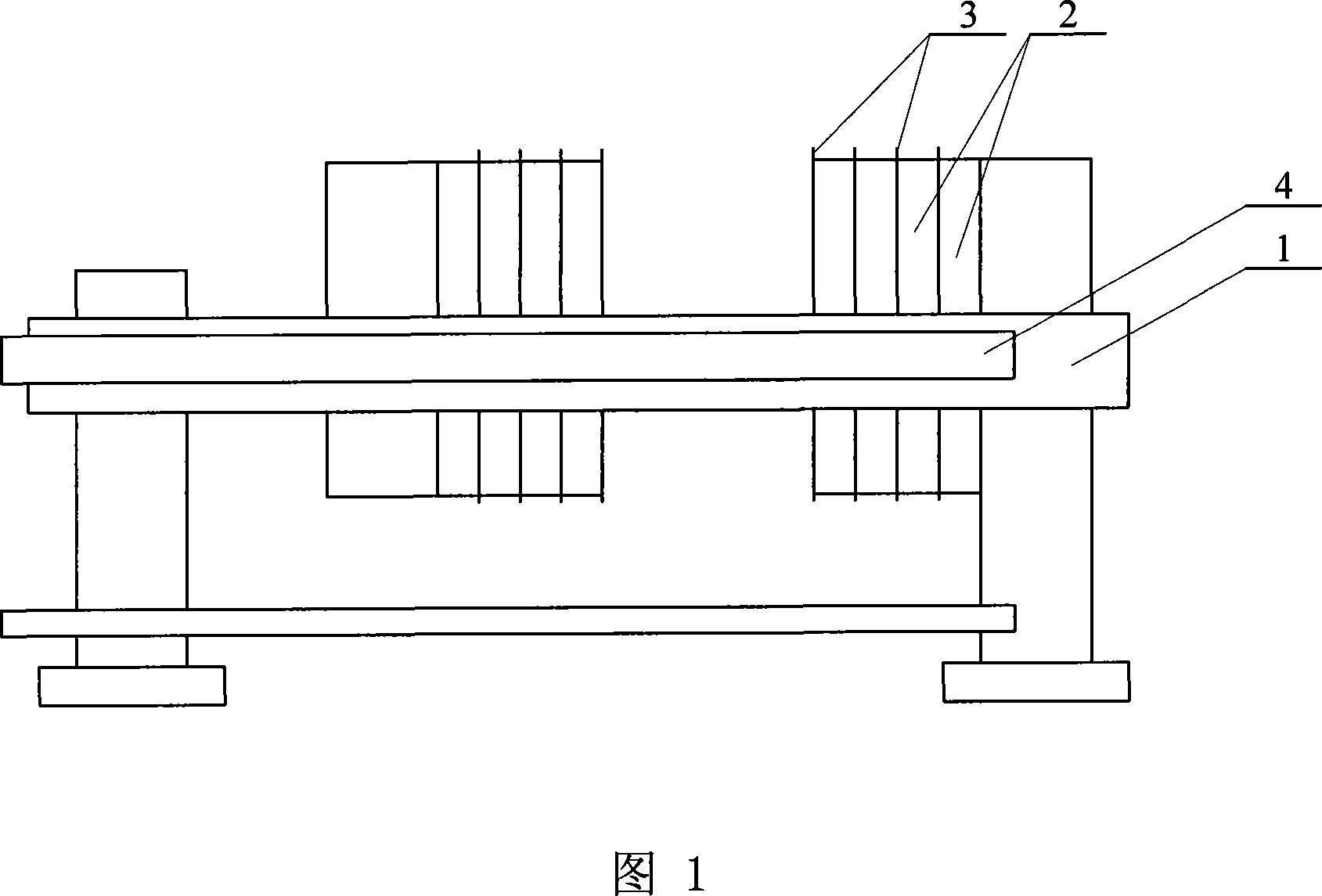

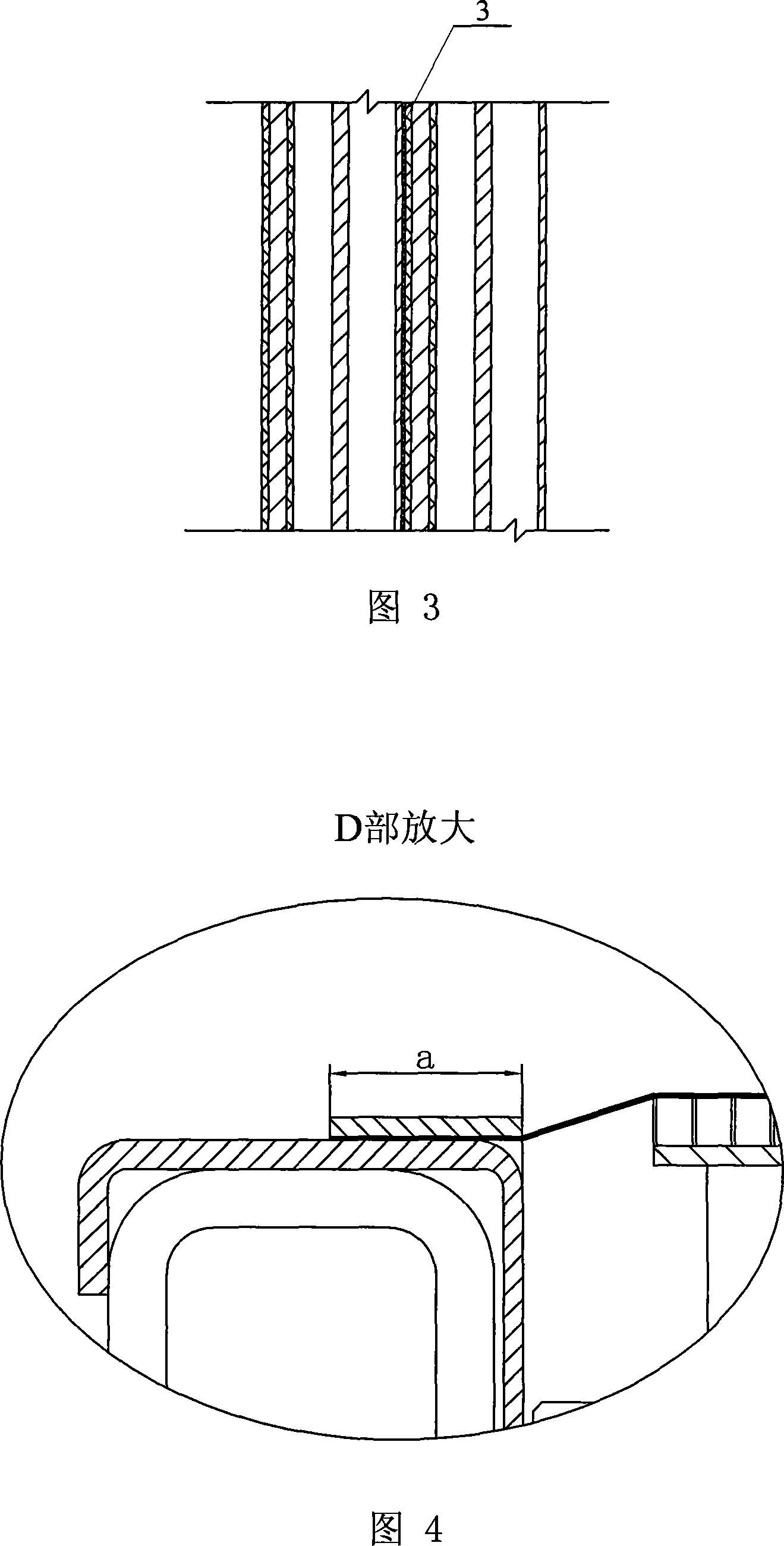

[0013] As shown in Figure 1, a certain number of unit electrolytic cells 2 are placed on the side bar 1 of the extruder of the present embodiment, and an ion membrane 3 is housed between every two unit electrolytic cells 2; There is only a distance in the dimension of film thickness between adjacent electrodes;

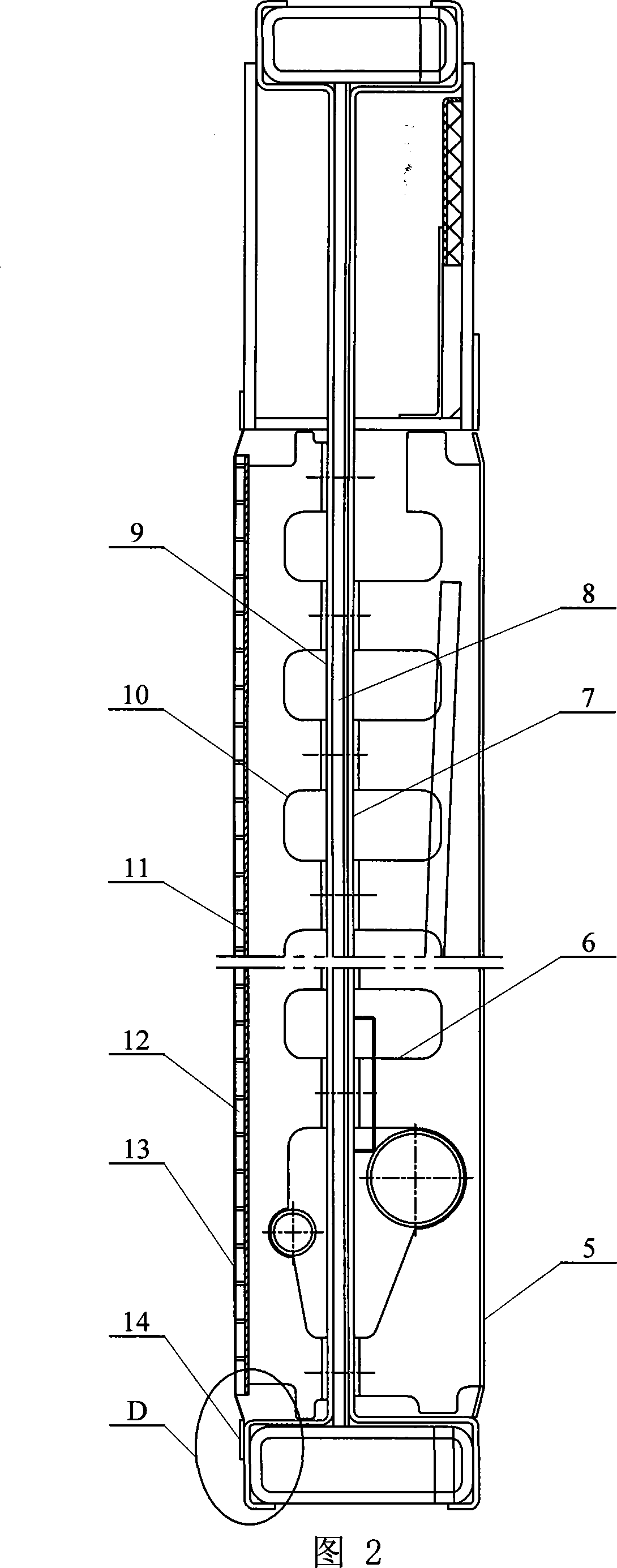

[0014] As shown in Figure 2, wherein, the anode 5, the anode side rib plate 6, and the anode disc 7 are connected by resistance welding to form the anode chamber of the electrolytic unit, and the supporting net 10, the cathode side rib plate 9, and the cathode disc 8 are also connected by resistance welding, The cathode chamber of the electrolysis unit is formed, and the cathode disk 9 and the anode disk 7 are respectively welded together with the conductive composite plate 8 sandwiched in the middle, and the cathode chamber and the anode chamber can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com