Exhaustion method for flushing water closestool

A method of exhausting and technology for flushing toilets, applied in flushing toilets, water supply devices, flushing equipment with water tanks, etc., can solve the problems of retention, long distance between fan and toilet, diffuse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The implementation of the present invention will be described in more detail below with reference to the drawings and reference numerals, so that those skilled in the art can implement it after studying this specification.

[0035] The inventor aims at combining the widely used separate toilet and single toilet with the exhaust device respectively, as a preferred embodiment, the implementation manner is described in detail below.

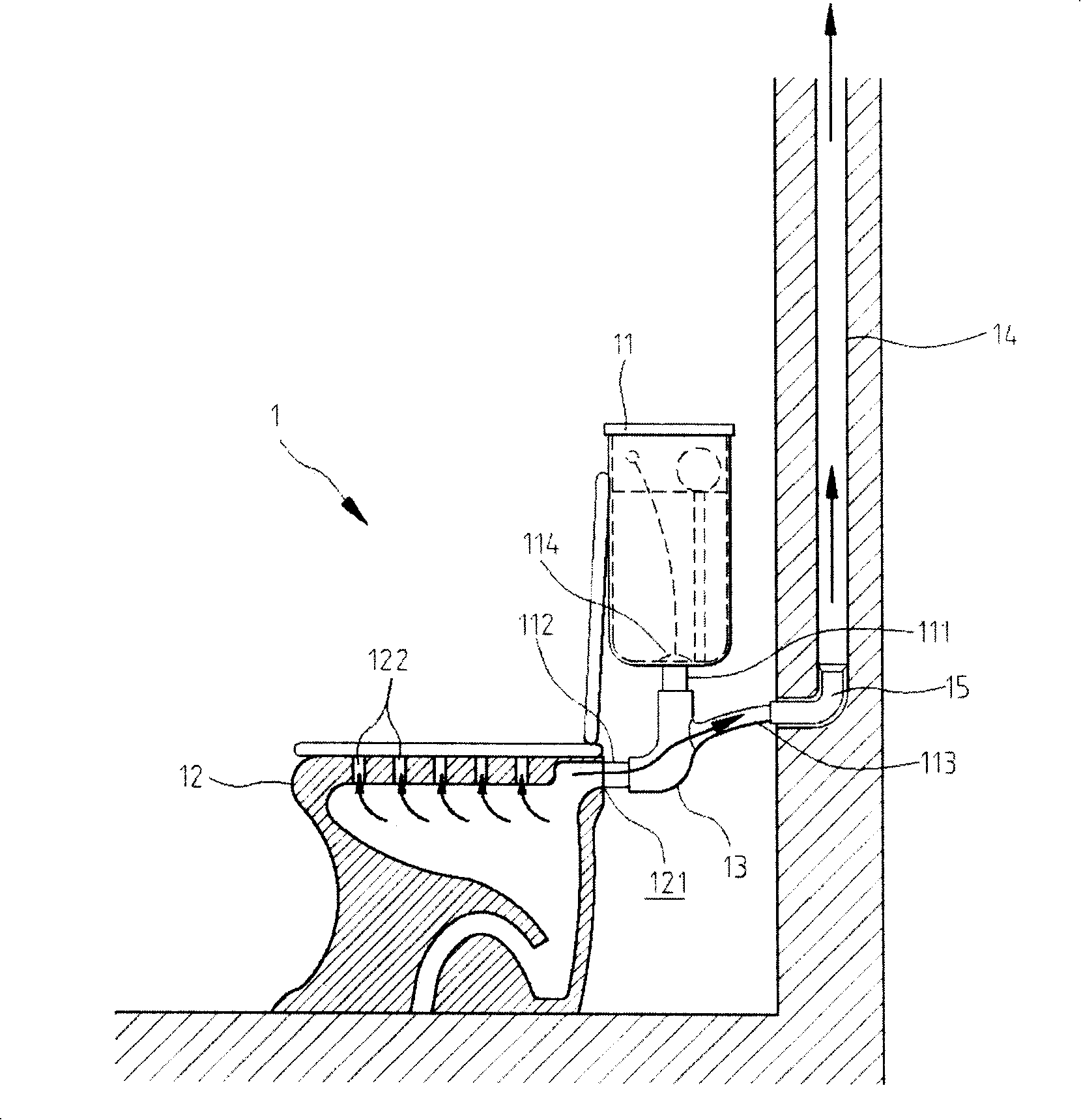

[0036] see figure 1 , which is a schematic diagram of a separate toilet combined with an exhaust device. The separated toilet 1 means that the water storage tank 11 of the toilet is separated from the toilet seat 12, and an extension pipe 111 is provided under the water storage tank 11, and another extension pipe 112 is provided at the main flushing hole 121 of the toilet seat 12. A three-pipe joint 13 is indirectly arranged between the pipes 111 and 112, and an air pipe 113 is connected to the remaining end of the three-pipe joint 13. The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com