Wall surface paint spraying and scraping machine

A technology of spraying and scraping machine and coating, applied in the direction of construction and building structure, can solve the problems of high labor intensity, low labor efficiency, large waste of materials, etc., to achieve the effect of beautiful wall, improve labor efficiency, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

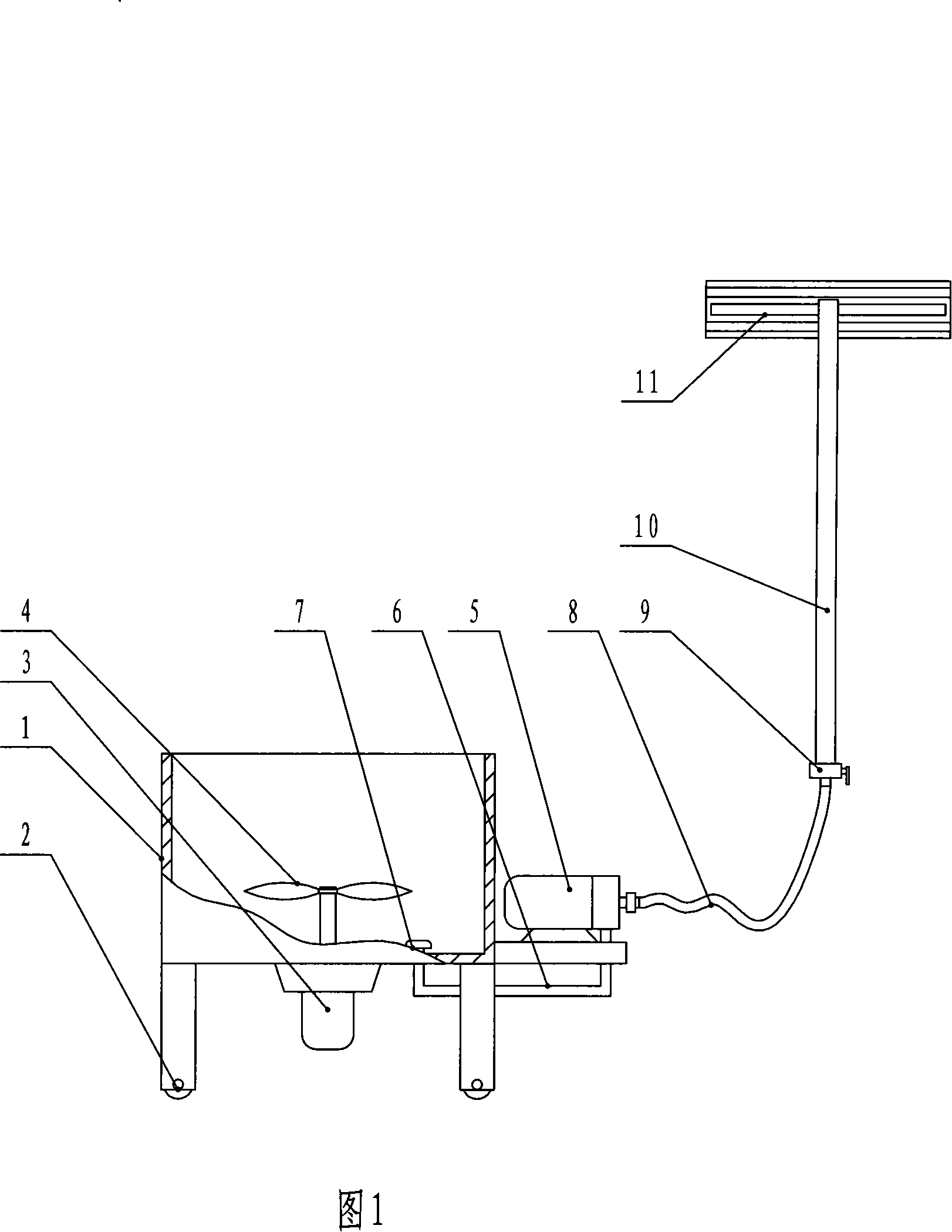

[0011] As shown in Fig. 1, Fig. 2 and Fig. 3, a wall paint spraying and scraping machine is equipped with a pulley [2] on the hopper 1, and an agitator 4 is installed in the hopper 1, and the agitator 4 passes through the bottom of the hopper 1. Driven by a motor 3, a conveying pump 5 is installed on the hopper 1, and the feeding pipe 6 of the conveying pump 5 is connected to the bottom of the hopper 1, and a filter cover 7 is installed at the inlet of the feeding pipe 6 in the hopper 1, and the feeding of the conveying pump 5 The pipe discharge pipe 8 is connected to one end of the hollow hand rod 10, and the connection between the discharge pipe 8 and the hollow hand rod 10 is equipped with a control valve 9, and the hollow hand rod 10 is connected to the spraying device. The spraying device includes a shell 11, and the shell Scraper 12 is housed on 11 sides, and a group of shower nozzle 13 is arranged in shell 11, and shower nozzle 13 is connected on the hollow hand bar 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com