Compressor

A technology for a compressor and a compression mechanism, applied in the field of compressors, can solve the problems of increased blade wear, decreased durability, compressor vibration, etc., and achieve the effects of suppressing discharge, improving durability, and reducing vibration and noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

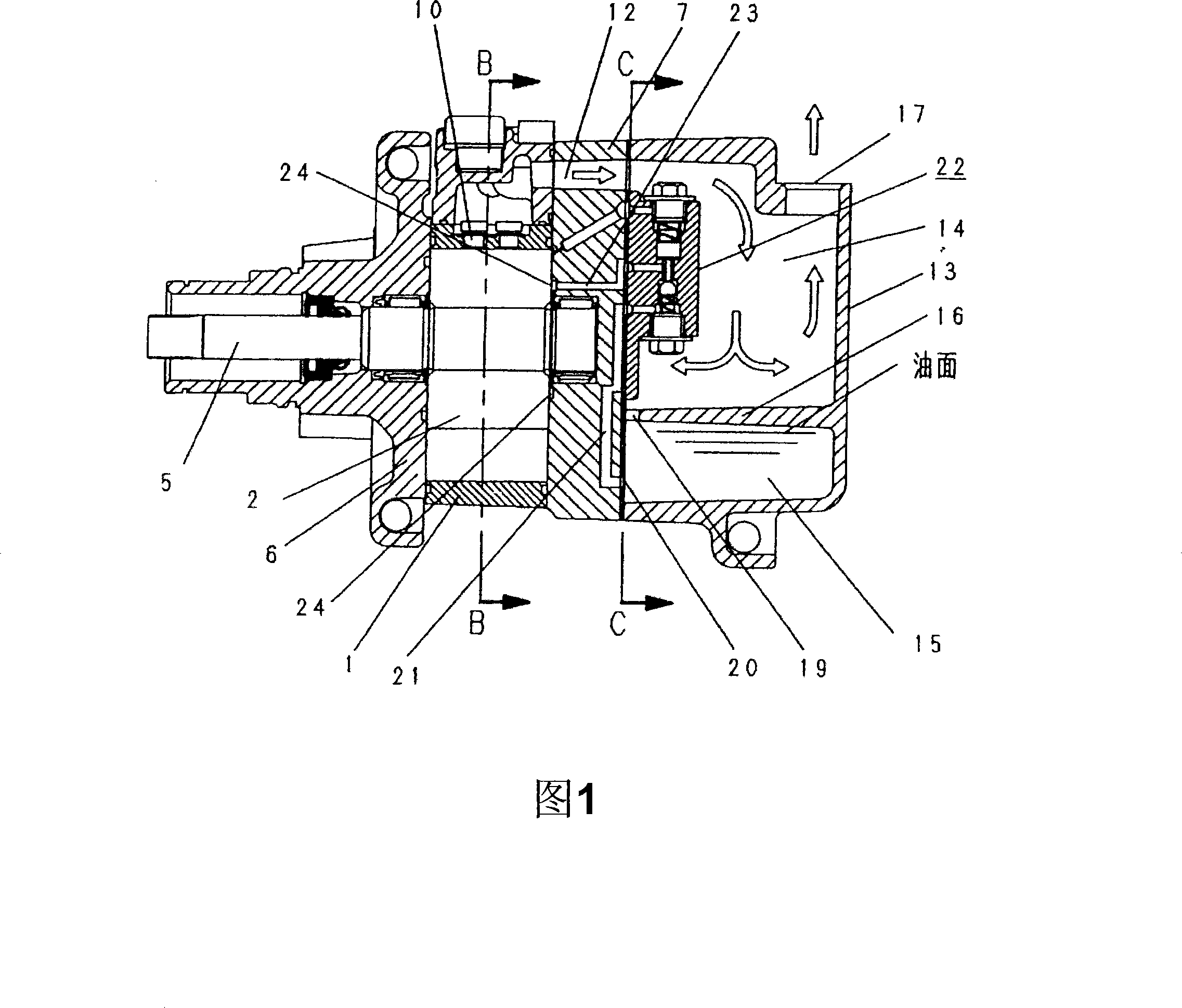

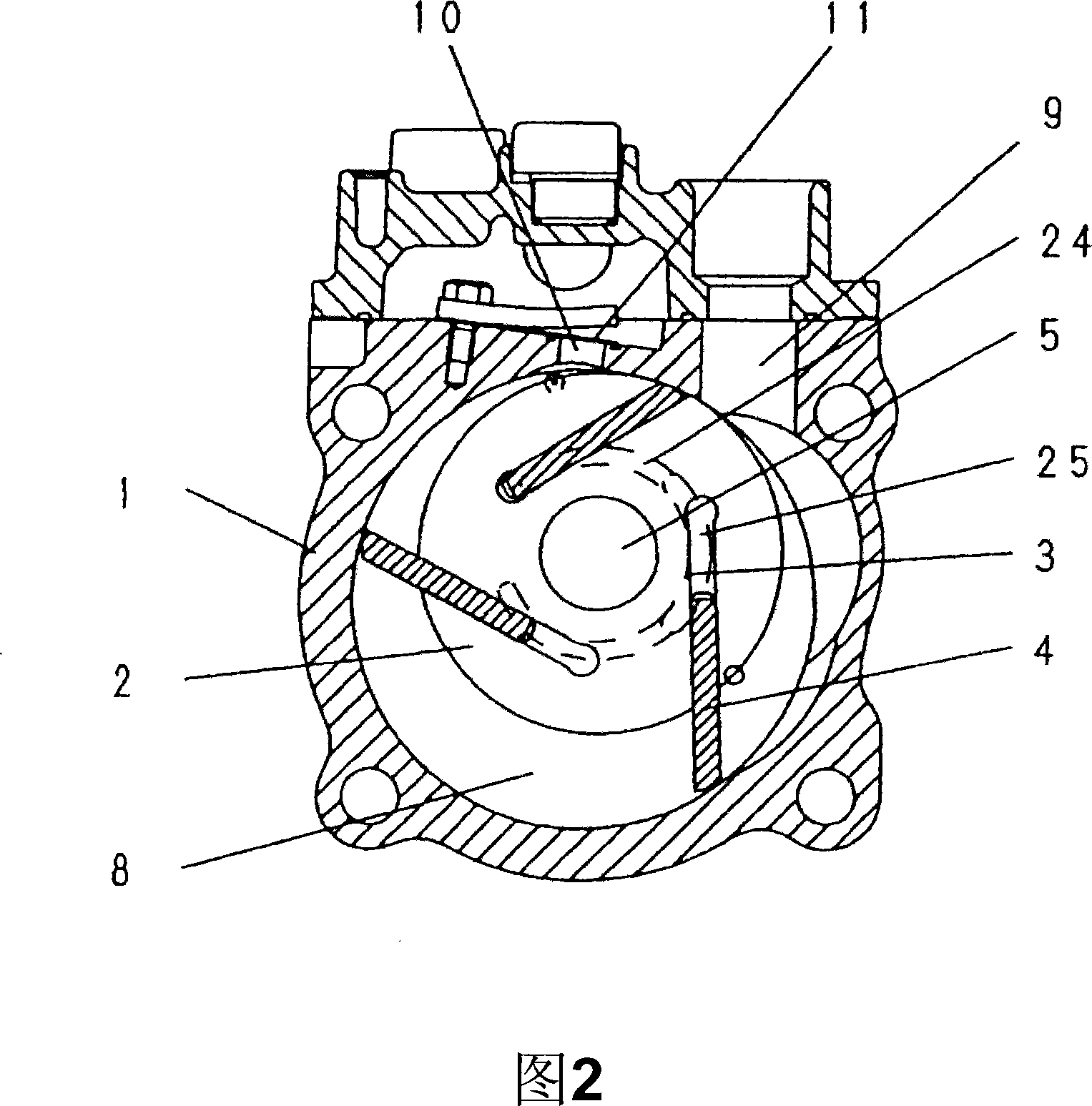

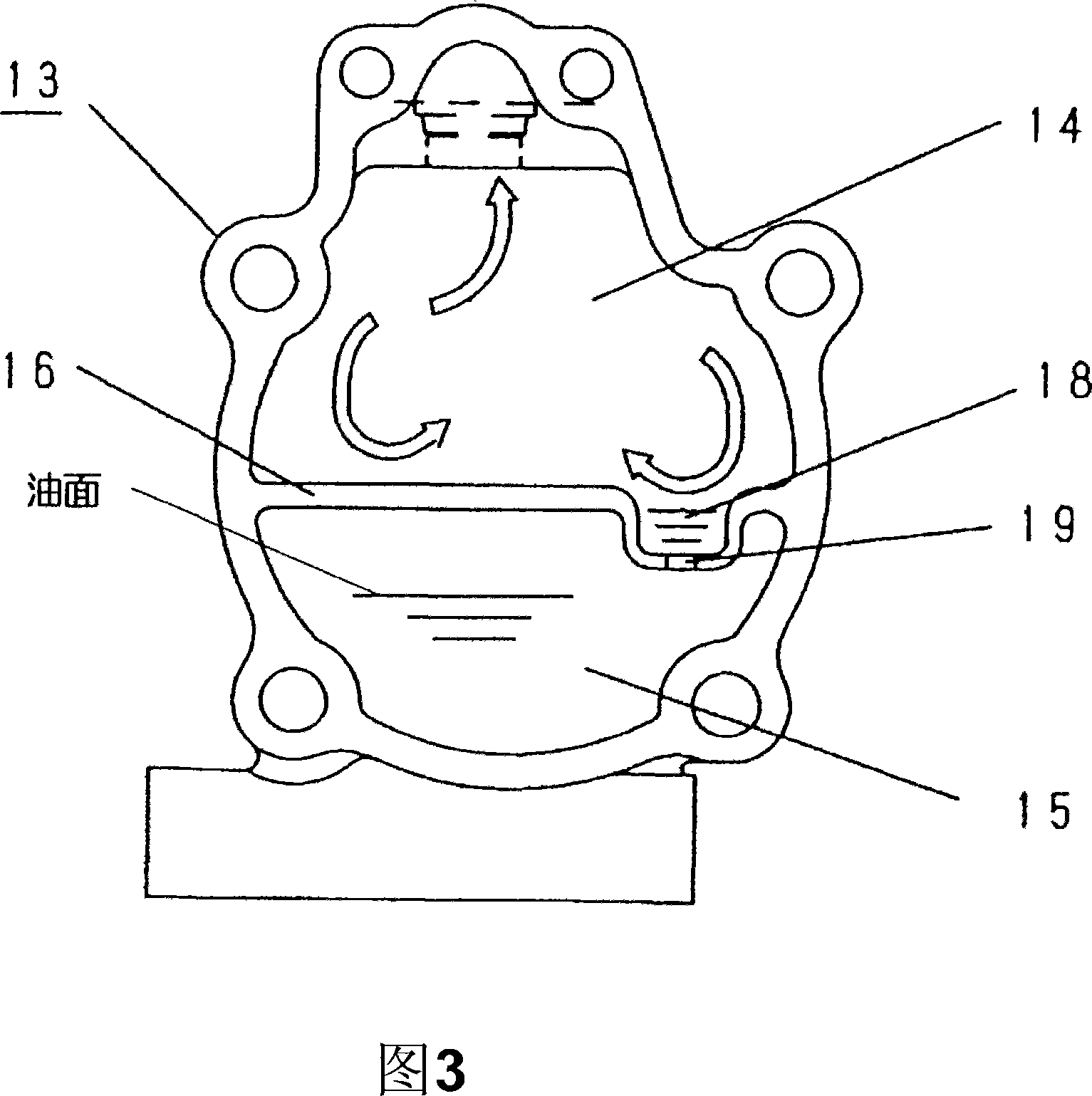

[0056] 1 to 3 show Embodiment 1 of the compressor of the present invention. In addition, although refrigerant|coolant is used and demonstrated in the following embodiment, it may be a compressor which compresses the gaseous fluid other than refrigerant|coolant. As shown in the figure, in this compressor, in a cylinder 1 having a cylindrical inner wall, a substantially cylindrical rotor 2 is accommodated with a part of its outer circumference forming a slight gap with the inner wall of the cylinder 1, and is freely rotatable. .

[0057] A plurality of vane slots (slots) 3 are provided at equal intervals on the rotor 2 , and vanes 4 that can slide freely are respectively inserted into the vane slots 3 . The rotor 2 is rotated by rotational drive of a drive shaft 5 integrally formed therewith.

[0058] Openings at both ends of the cylinder 1 are closed by a front side plate 6 and a rear side plate 7 , and a working chamber 8 is formed inside the cylinder 1 . The working chambe...

Embodiment approach 2

[0068] Next, another embodiment of the compressor of the present invention will be described with reference to FIG. 4 . In addition, the same reference numerals are assigned to components substantially the same as those in the above-mentioned embodiment, and description thereof will be omitted, and only differences will be described.

[0069] In the compressor of the present embodiment, a part of the partition wall 16 is an inclined surface, and the inclined surface forms a concave portion protruding toward the oil storage chamber 15 as the oil accumulation portion 18 . A first straightening plate 26 b is provided at a position facing the inclined surface in the high pressure chamber 14 . By arranging the front end of the first straightening plate 26b to face the inclined surface, the main flow of the refrigerant does not flow into the oil reservoir 18 . In addition, a second straightening plate 26 a other than the first straightening plate 26 b is provided in the high-pressu...

Embodiment approach 3

[0072] Next, other embodiments of the compressor of the present invention will be described with reference to FIGS. 5 and 6 . In addition, the same reference numerals are assigned to components substantially the same as those in the above-mentioned embodiment, and description thereof will be omitted, and only differences will be described.

[0073] In the compressor of the present embodiment, the area of the communication passage 19 is such that lubricating oil separated from the refrigerant is discharged to the oil storage chamber 15 without being accumulated in the oil reservoir 18 .

[0074] In this embodiment, it is preferable that the size and passage area of the communication passage 19 be an appropriate size selected according to the viscosity of the lubricating oil used. Specifically, the width of the communication passage 19 is 1 cm, the depth is 3 cm, and the passage area is 3 cm. 2 .

[0075] By adopting the above method, during operation, since the amount of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com