Novel flexible flat sheet membrane element

A flat membrane, flexible technology, applied in the field of new flexible flat membrane elements and sewage treatment technology, can solve the problems of high investment cost of flat membrane elements, unfavorable popularization and application, etc., to achieve beneficial aeration, reduce aeration volume, and reduce investment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

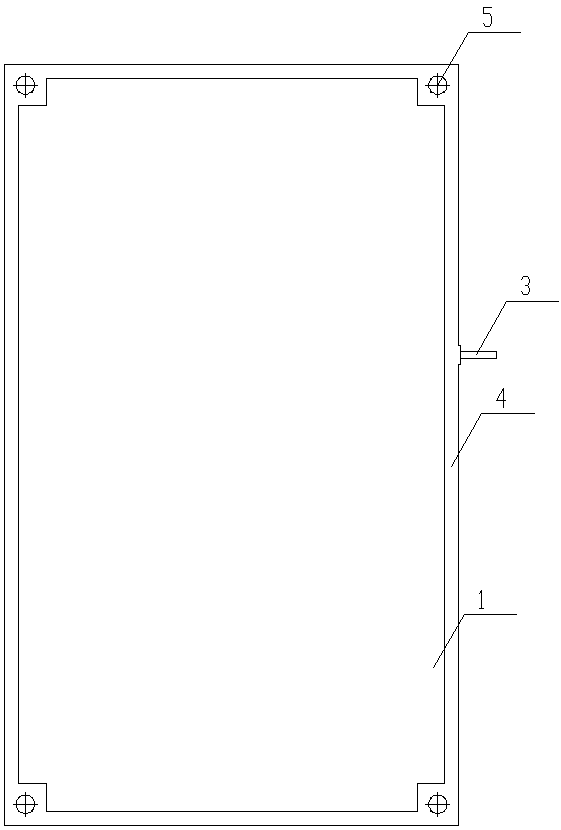

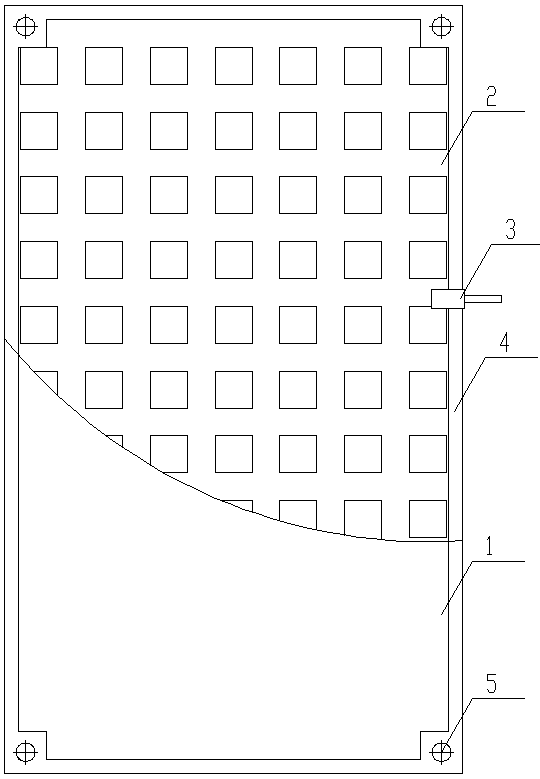

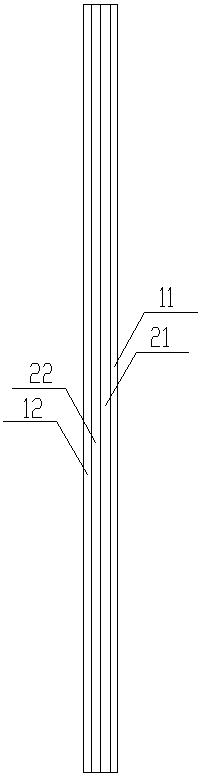

[0029] Refer to Figure 1 ~ Figure 4 , A new type of flexible flat membrane element includes diaphragm 1, diversion net 2 and water production port 3. Among them: diaphragm 1 includes diaphragm one 11 and diaphragm two 12, diversion net 2 includes diversion net 21 and guide Flow net two 22, diaphragm one 11 and diaphragm two 12 are connected and the diversion net 21 and diversion net two 22 are enclosed in diaphragm one 11 and diaphragm two 12, diversion net 21 and diversion net There is a water production port 3 between 22 and 22.

[0030] Combine figure 1 As shown in Fig. 4, the periphery of the diaphragm one 11 and the diaphragm two 12 are heat-sealed and bonded together with a hot-melt adhesive strip 4 of a certain width. Hot melt adhesive has the advantages of smooth surface, soft quality, acid and alkali corrosion resistance, oxidation resistance, etc., which avoids the problem of brittleness and cracking of flat film materials when using conventional adhesives or the temp...

Embodiment 2

[0036] Refer to Figure 1 ~ Figure 4 , A new type of flexible flat membrane element includes diaphragm 1, diversion net 2 and water production port 3. Among them: diaphragm 1 includes diaphragm one 11 and diaphragm two 12, diversion net 2 includes diversion net 21 and guide Flow net two 22, diaphragm one 11 and diaphragm two 12 are connected and the diversion net 21 and diversion net two 22 are enclosed in diaphragm one 11 and diaphragm two 12, diversion net 21 and diversion net There is a water production port 3 between 22 and 22.

[0037] Combine figure 1 As shown in Fig. 4, the periphery of the diaphragm one 11 and the diaphragm two 12 are heat-sealed and bonded together with a hot-melt adhesive strip 4 of a certain width. Hot melt adhesive has the advantages of smooth surface, soft quality, acid and alkali corrosion resistance, oxidation resistance, etc., which avoids the problem of brittleness and cracking of flat film materials when using conventional adhesives or the temp...

Embodiment 3

[0044] Refer to Figure 1 ~ Figure 4 , A new type of flexible flat membrane element includes diaphragm 1, diversion net 2 and water production port 3. Among them: diaphragm 1 includes diaphragm one 11 and diaphragm two 12, diversion net 2 includes diversion net 21 and guide Flow net two 22, diaphragm one 11 and diaphragm two 12 are connected and the diversion net 21 and diversion net two 22 are enclosed in diaphragm one 11 and diaphragm two 12, diversion net 21 and diversion net There is a water production port 3 between 22 and 22.

[0045] Combine figure 1 As shown in Fig. 4, the periphery of the diaphragm one 11 and the diaphragm two 12 are heat-sealed and bonded together with a hot-melt adhesive strip 4 of a certain width. Hot melt adhesive has the advantages of smooth surface, soft quality, acid and alkali corrosion resistance, oxidation resistance, etc., which avoids the problem of brittleness and cracking of flat film materials when using conventional adhesives or the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com