Air valve and air sealing body with the same

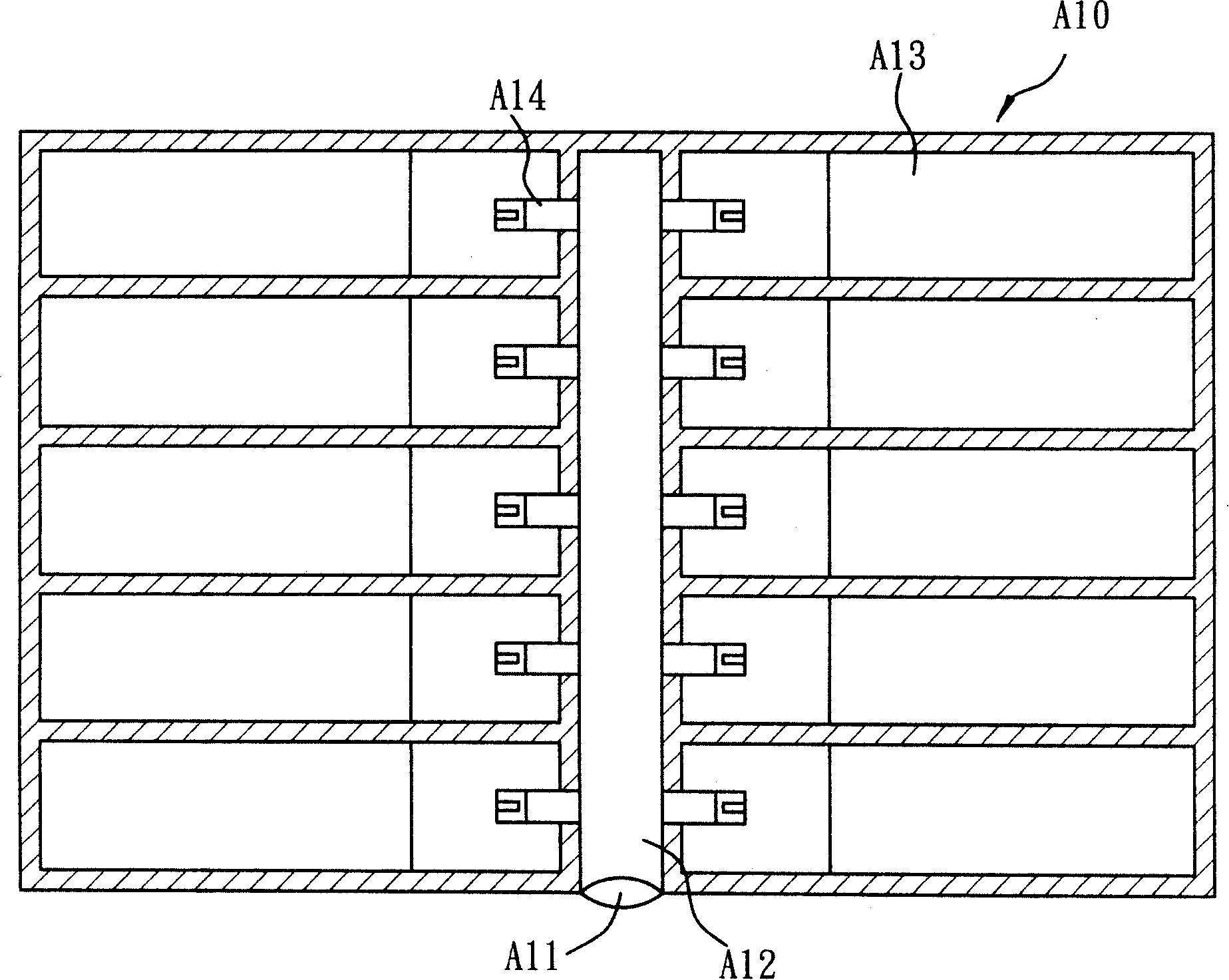

A technology of air sealing body and air stop valve, which is applied in the direction of preventing mechanical damage, control valve, valve device, etc. It can solve the problem of poor cushioning effect of gas packaging bag A10, increased production process and manufacturing cost, and poor inflation effect. It can reduce the production process, simplify the structure, and facilitate the production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

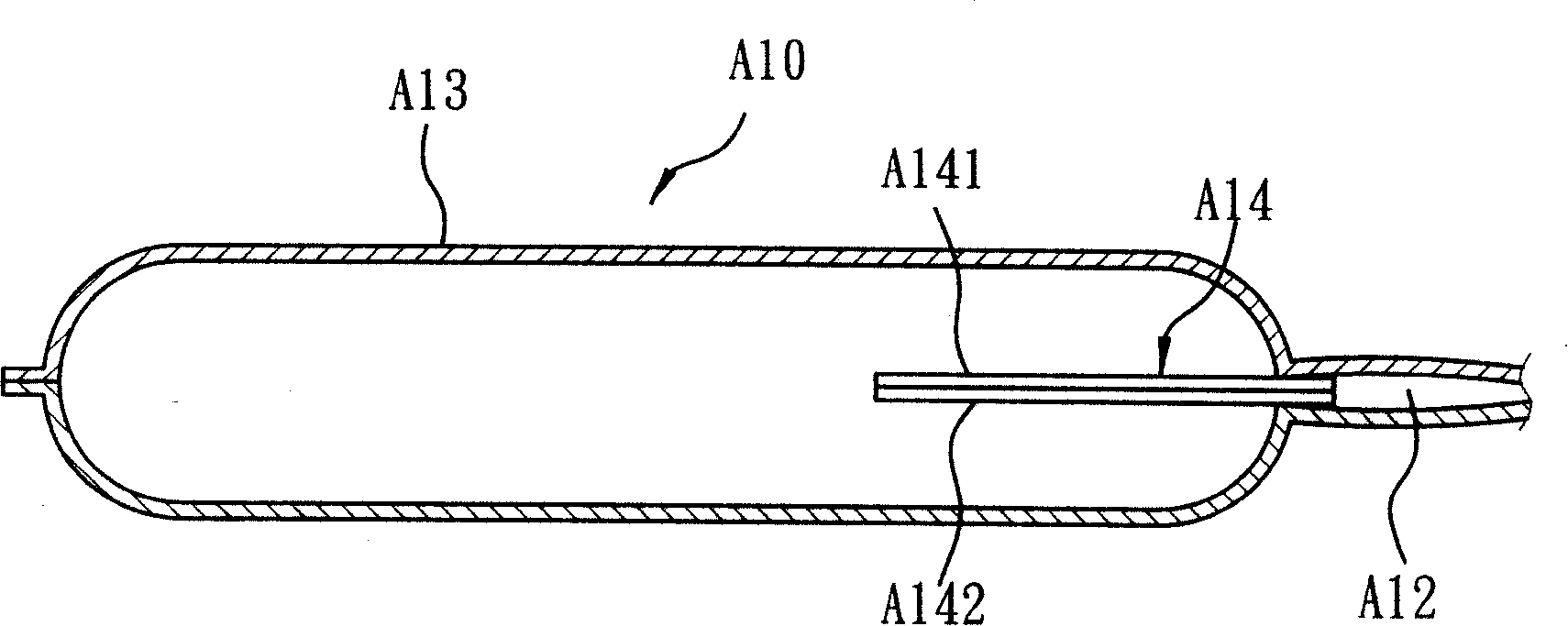

[0044] figure 2 , image 3 , Figure 4A and Figure 4B Shown is Example 1 of the present invention. in figure 2 The shown air stop valve of the present invention includes: two inner membranes 1a and 1b, a heat-resistant material 1c, an air inlet 2e, an air channel 5, and a cut hole 8.

[0045] The two inner membranes 1a and 1b are stacked up and down, and heat-resistant material 1c is coated inside. The heat-resistant material 1c starts from the top of the inner membrane and extends downward for a certain length. Glue or ink, so that the heat-resistant material 1c is bonded on the two inner films 1a or 1b by heat sealing. The shape of the heat-resistant material is elongated, oval or T-shaped with a wide top and a narrow bottom.

[0046] The peripheries of the four sides of the inner film 1a and 1b are bonded in a heat-sealing manner to form heat-sealing lines 3a, 3b, 3c, and 3d, wherein the heat-sealing lines 3a, 3b, and 3c are completely closed heat-sealing lines, an...

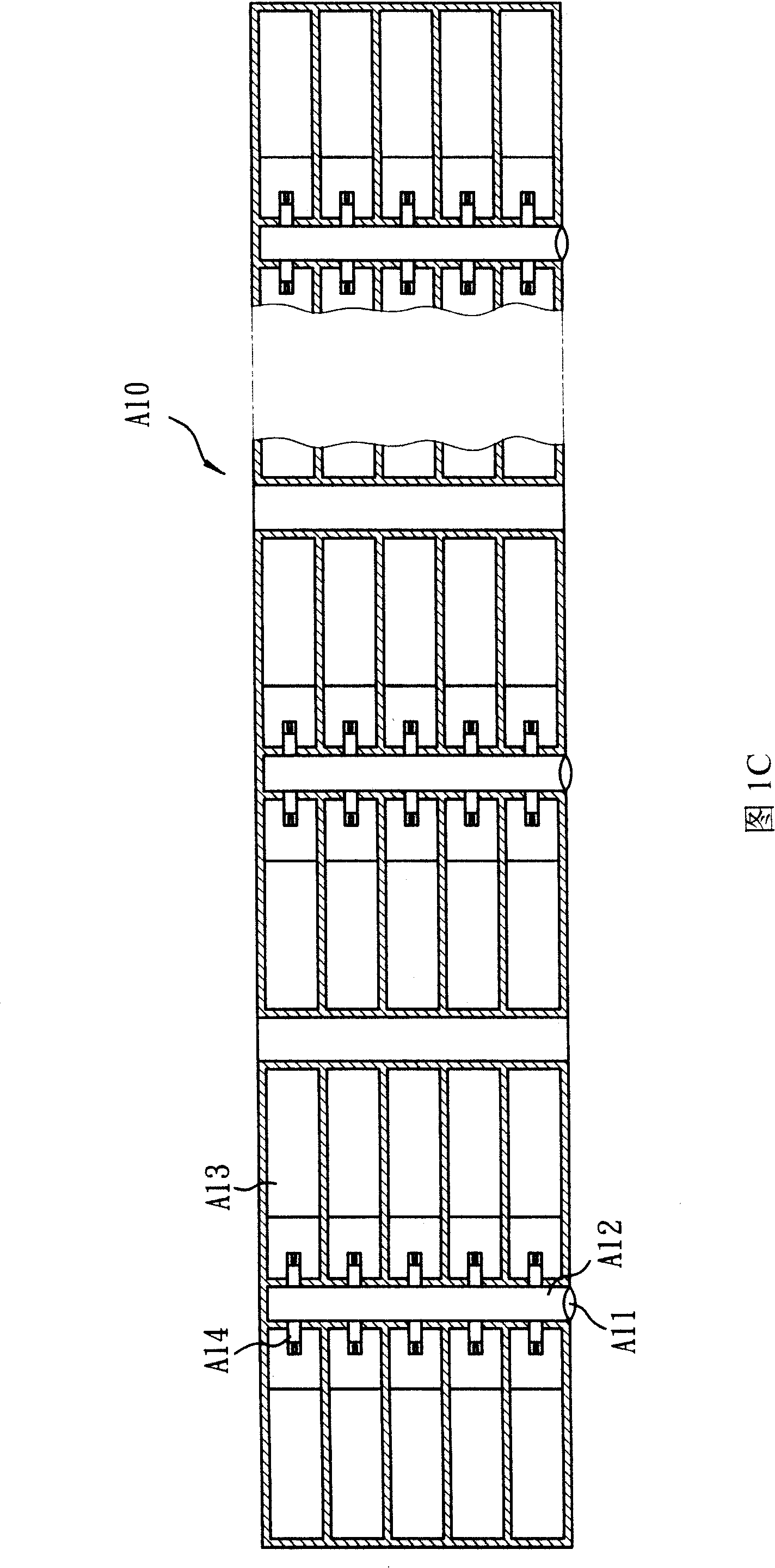

Embodiment 2

[0055] Such as Figure 5 Shown, the stop valve of present embodiment 2 and embodiment 1 (see figure 2 ) is that the gas channel 5 of the present embodiment 2 is longer and includes a plurality of bronchial channels 6, and the incision hole 8 is located at the end of the bronchial channel, so the bronchial channel 6 is used to connect the gas channel 5 and the incision hole 8. The bronchi are formed by bonding the two inner membranes by heat sealing.

[0056] When inflated, the two inner membranes 1a and 1b of the stop valve are pulled apart, thereby opening the air inlet 2e, allowing external air to enter the gas channel 5 through the air inlet 2e, and along the gas channel 5, and its respective The air passages 6 and the cut holes 8 flow into the air chamber 40 of the air-tight body to inflate the air chamber 40 .

Embodiment 3

[0058] Such as Figure 6 As shown, the difference between this embodiment 3 and the above-mentioned embodiment 1 is that the gas stop valve of this embodiment 3 includes a plurality of gas channels 5 uniformly arranged in the transverse direction, and the upper end of each gas channel 5 is connected to the gas inlet 2e A plurality of cut holes 8 are arranged on the side of each gas channel 5 .

[0059] The heat-sealing line 3d does not completely bond the peripheral edges of the two inner membranes, and the place with the heat-resistant material 1c is not bonded, and the place without the heat-resistant material 1c is bonded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com