Wafer adsorption mechanism

A technology of adsorption mechanism and wafer, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of loss of detection accuracy and easy deformation of the substrate, saving manpower, reducing requirements, and reasonable and reliable structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

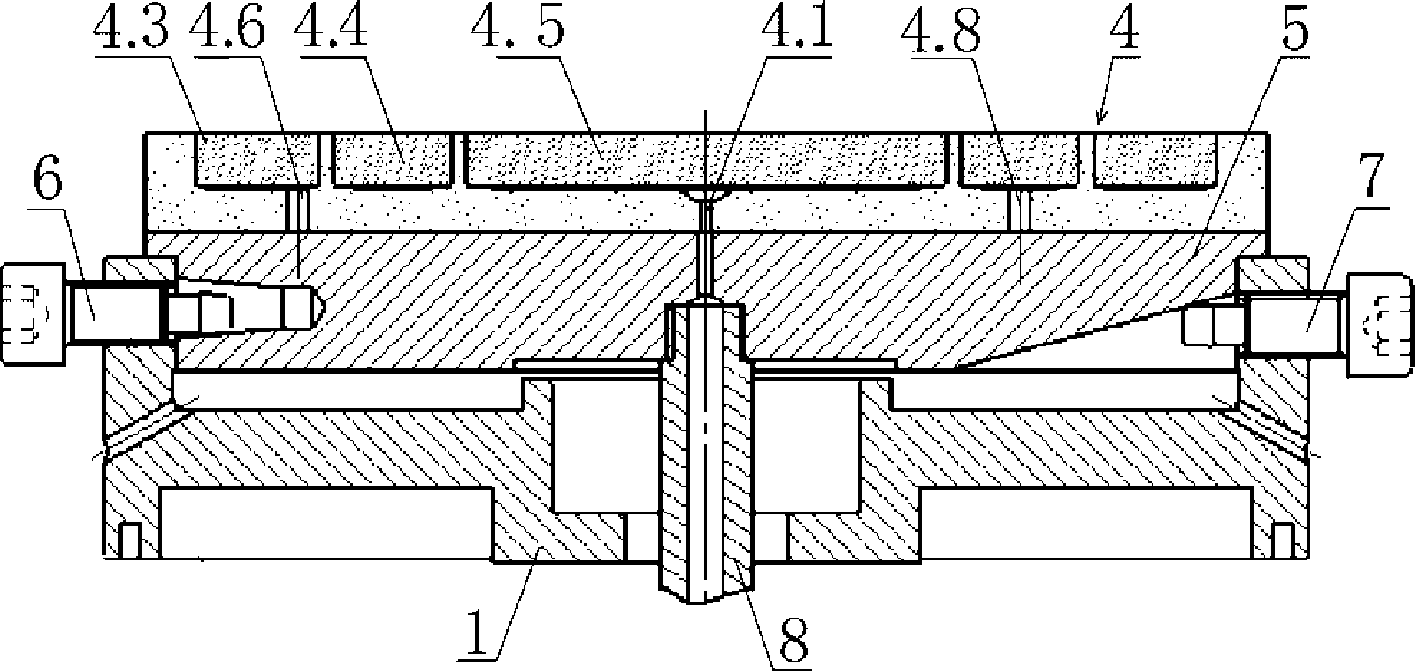

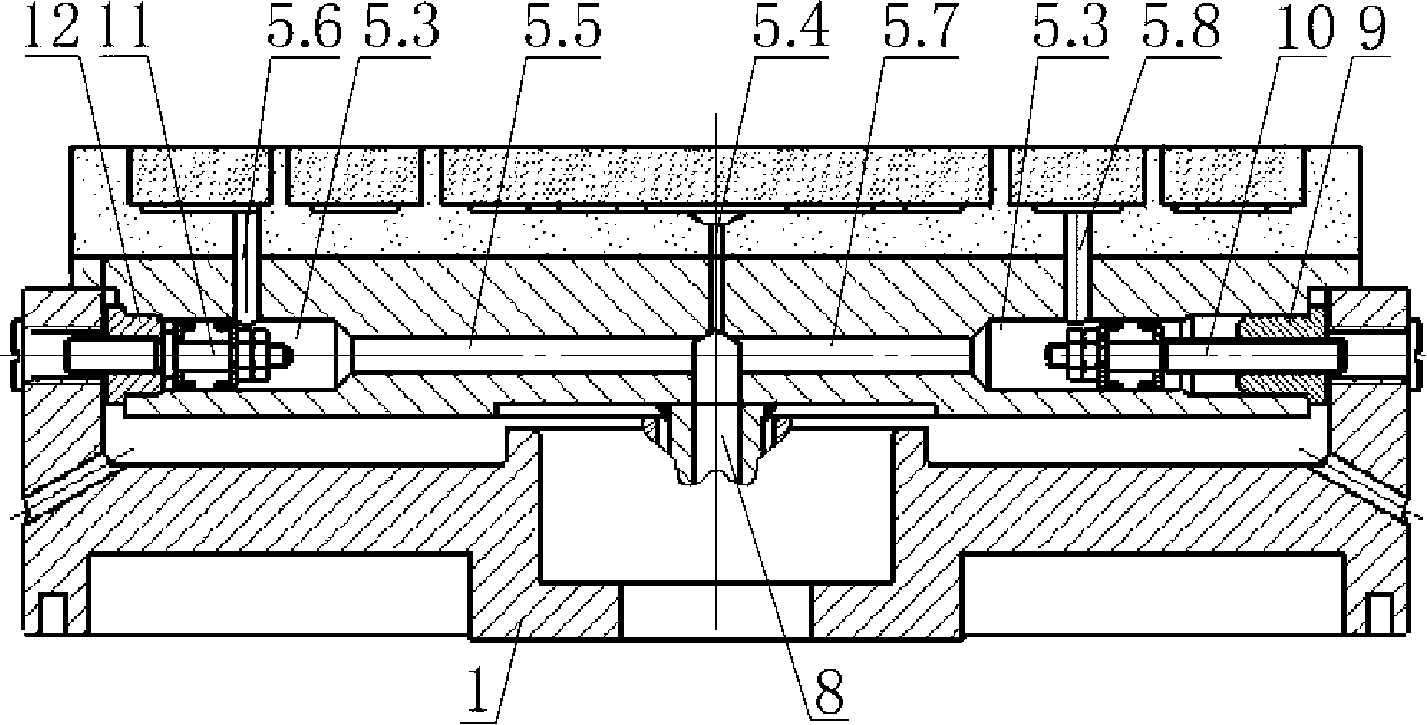

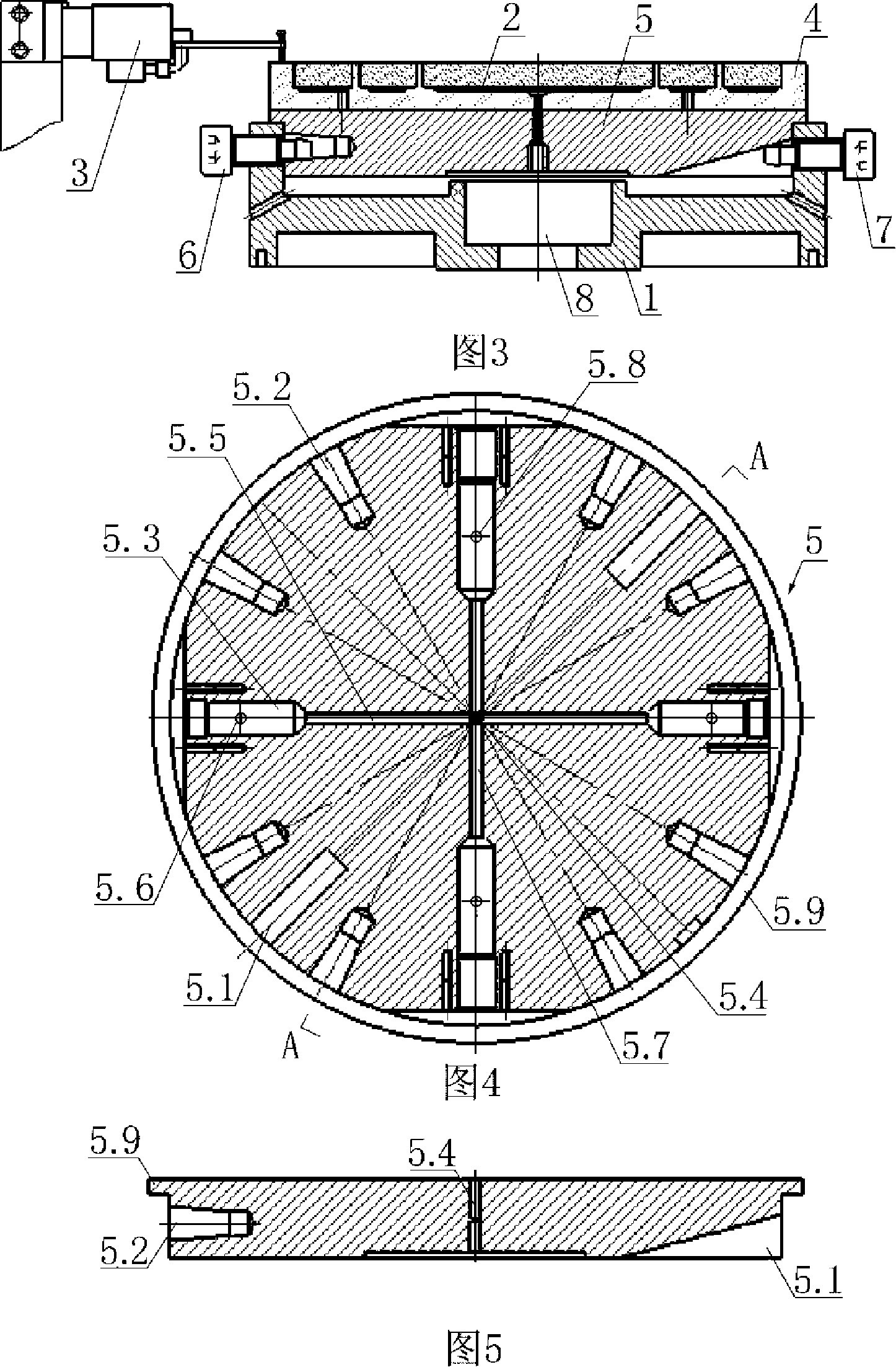

[0041] Examples see figure 1 As shown in -3, this wafer adsorption mechanism includes a mounting plate 1, a base plate 4 on the mounting plate and a vacuum system, and the online detector 3 is generally located at the edge of the base plate 4. An air duct 8 is connected from the mounting plate to the base plate 4 .

[0042] Referring to Fig. 4-5, there is an adjustment bottom plate 5 between the installation plate 1 and the base plate 4. The adjustment bottom plate 5 requires high machining accuracy, and the material is 3Cr13. The adjustment bottom plate 5 is supported on the bottom of the base plate 4, wedge-shaped lifting grooves 5.1 are symmetrically distributed on the edge of the bottom surface of the adjustment bottom plate 5, fastening screw holes 5.2 are evenly opened on the sides of the adjustment bottom plate 5, and the center of the adjustment bottom plate 5 is opened with The central hole 4.1 of the base plate corresponds to the central hole 5.4 of the adjustment b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com