Tectorial membrane forming device for forming tectorial membrane on internal surface of container, production method for internal surface tectorial membrane container

An inner surface and container technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of unstable discharge, reduced power efficiency, reduced power, etc. stable effect

Inactive Publication Date: 2010-12-01

MITSUBISHI HEAVY IND MACHINERY SYST LTD

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

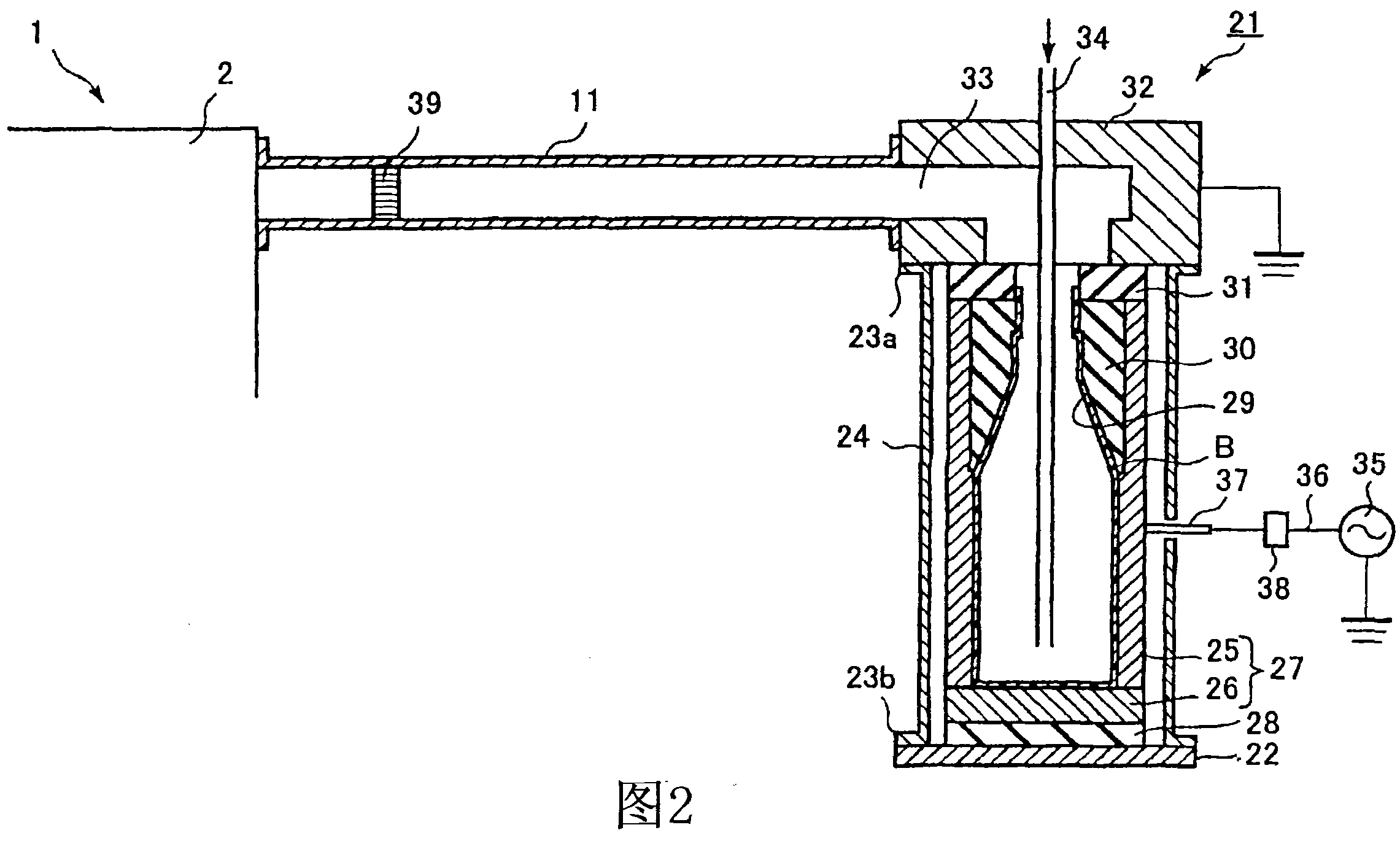

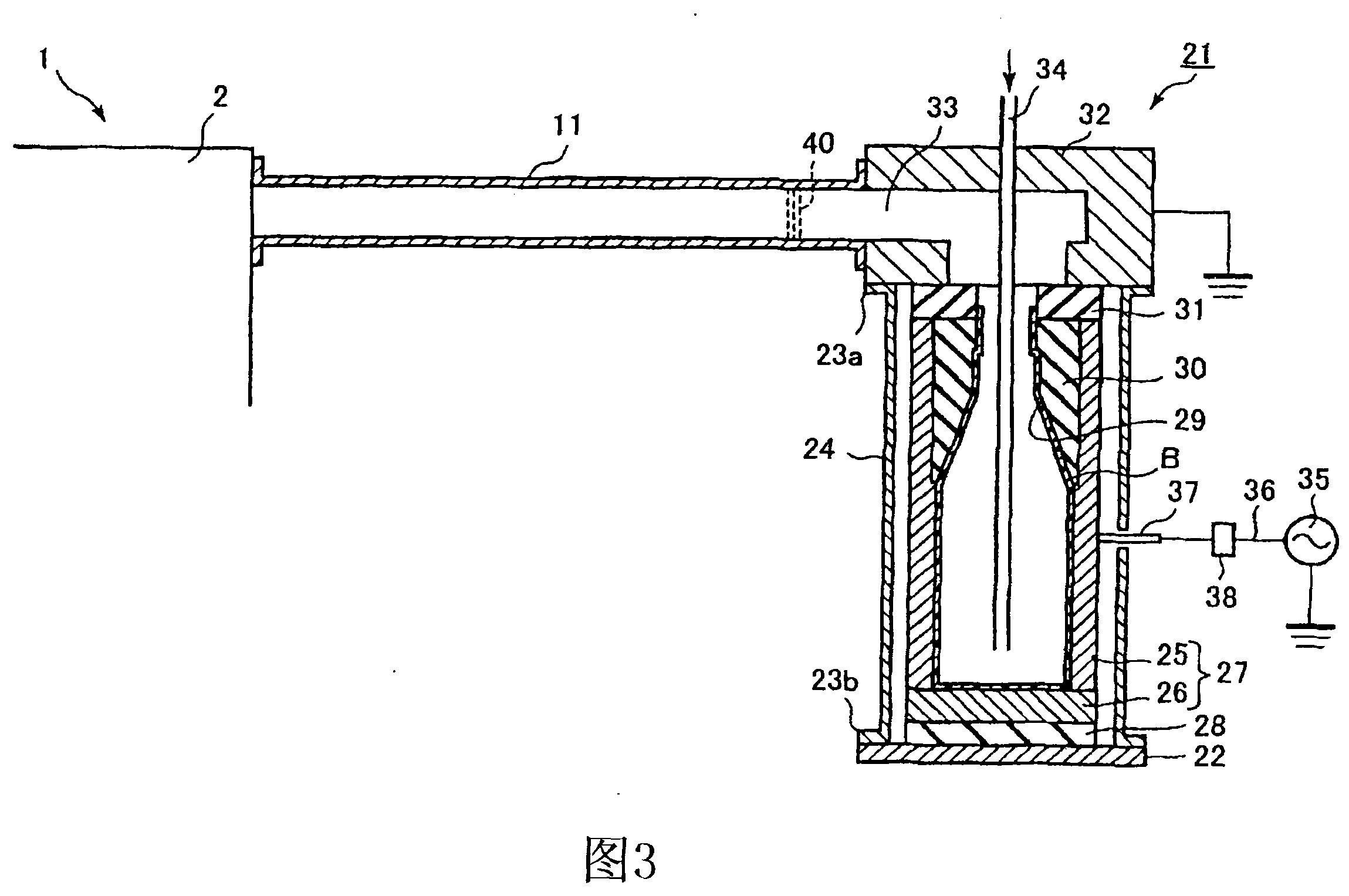

However, in the carbon film forming apparatus having the above-mentioned structure, a plurality of film forming chambers having external electrodes and exhaust pipes are prepared, and the exhaust pipes (branch exhaust pipes) for these film forming chambers are respectively connected with the rotating exhaust pipes as exhaust means. When connected to the rotary vacuum sealing mechanism, there is a problem that the above-mentioned discharge area reaches the rotary vacuum sealing mechanism through the exhaust pipe

Furthermore, it may interfere with the discharge (plasma) of the above-mentioned rotary vacuum sealing mechanism that has reached other adjacent film forming chambers, resulting in unstable discharge and abnormal power supply.

In addition, when the discharge area extends to the exhaust pipe, the power injected into the PET bottle decreases, resulting in a decrease in power efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

no. 1 approach

Embodiment 1

no. 2 approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

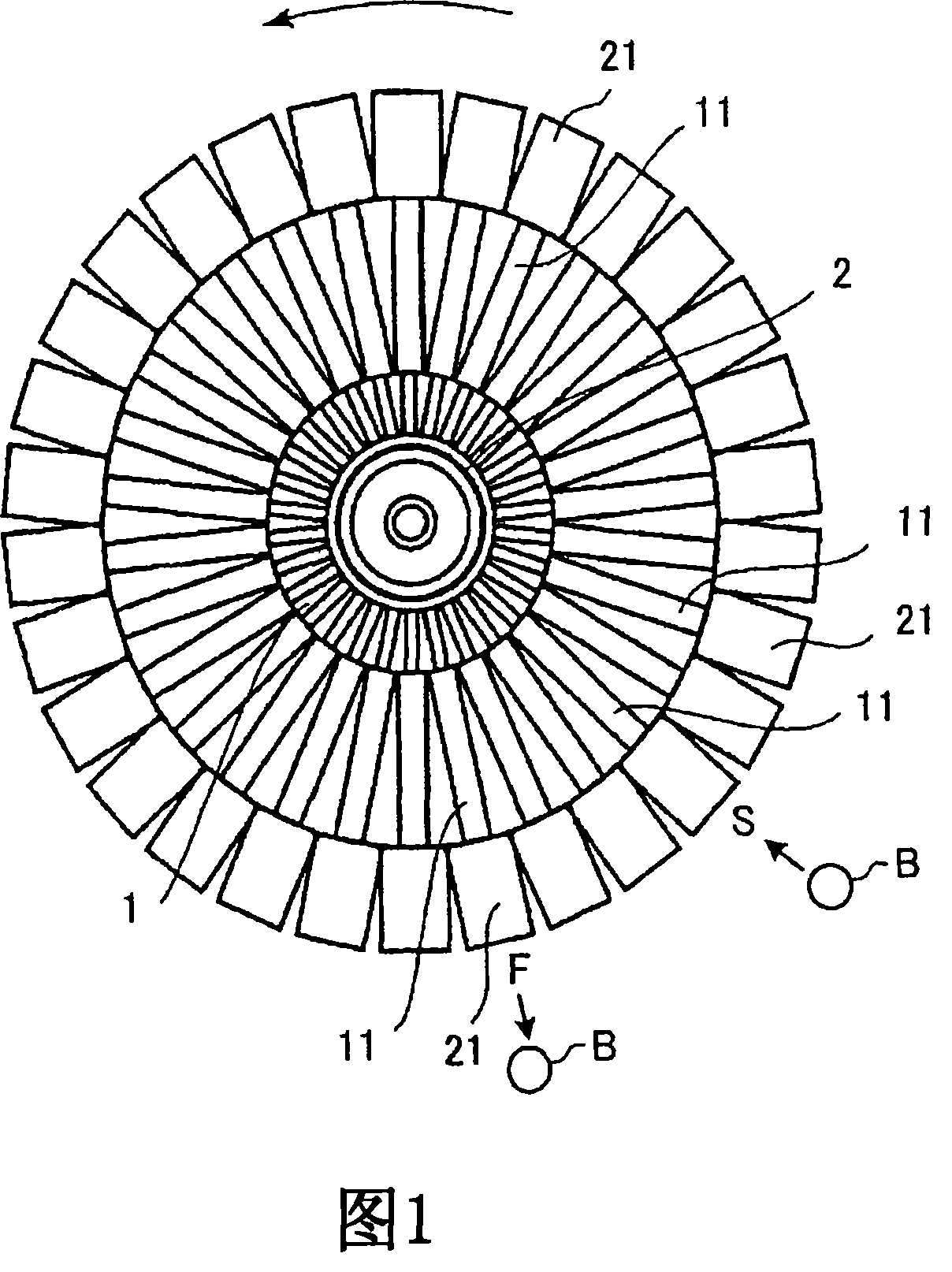

A device for forming a coating film on the inner surface of a container comprising a plurality of film-forming chambers (21) communicating with a rotary vacuum sealing mechanism (1) through an exhaust pipe (11) to form a coating film on the inner surface of a plastic bottle B. The exhaust pipe is made of a conductive material and arranged, at a desired position in the pipe, with a honeycomb conductor (39), i.e. a breathing and conductive electric field shielding member. The film-forming chamber comprises an external electrode (27) having a cavity large enough to surround a container when it is inserted, a conductive chamber header member (32) fixed to the end face of the external electrode on the side where the mouth of the container is located through an insulating member (31) and being connected with the exhaust pipe and earthed, a member (34) being inserted into the container in the external electrode (27) from the chamber header member side and blowing coating film forming gas, and a high frequency power supply (35) as an electric field imparting means for imparting an electric field between the external electrode and the earthed chamber header member and exhaust pipe.

Description

Film forming apparatus for forming film on inner surface of container, and method of manufacturing inner surface film-coated container technical field The present invention relates to a coating forming device for coating the inner surface of a container and a method for manufacturing an inner surface coating container. Background technique Plastic containers, such as PET bottles, try to form a barrier film on the inner surface, such as DLC (Diamond Like Carbon, diamond-like carbon) and other carbons, in order to prevent oxygen from the outside and / or prevent carbon dioxide from the inside (such as carbonated drinks). film (Patent Document 1). As such a method of forming a carbon film on the inner wall surface of a plastic container, it is described in Patent Document 2 which the present applicant has applied for and published. In FIG. 7 of this patent document 2, a carbon film forming apparatus for forming a carbon film on the inner surface of a plastic container is disc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Patents(China)

IPC IPC(8): C23C16/44C23C16/507

CPCC23C16/507C23C16/045C23C16/4412C23C16/50

Inventor 山越英男浅原裕司上田敦士石濑文彦中地正明

Owner MITSUBISHI HEAVY IND MACHINERY SYST LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap