High-molybdenum high-vanadium microsegregation cast high speed steel for rolls

A technology of micro-segregation and high-speed steel, which is applied in the field of rolling steel manufacturing, can solve problems affecting the uniformity of roll radial performance, W gravity segregation, large W content, etc., and achieve the effect of improving mechanical properties, performance improvement, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Dosing according to the chemical composition designed in the present invention, using a conventional intermediate frequency vacuum induction furnace to smelt one furnace of steel, and then using a vertical centrifugal method to cast a roller sleeve; Composite method produces two high-speed steel rolls with a roll body diameter of Φ500mm and a working layer thickness of 50mm. Its components are shown in Table 1 respectively.

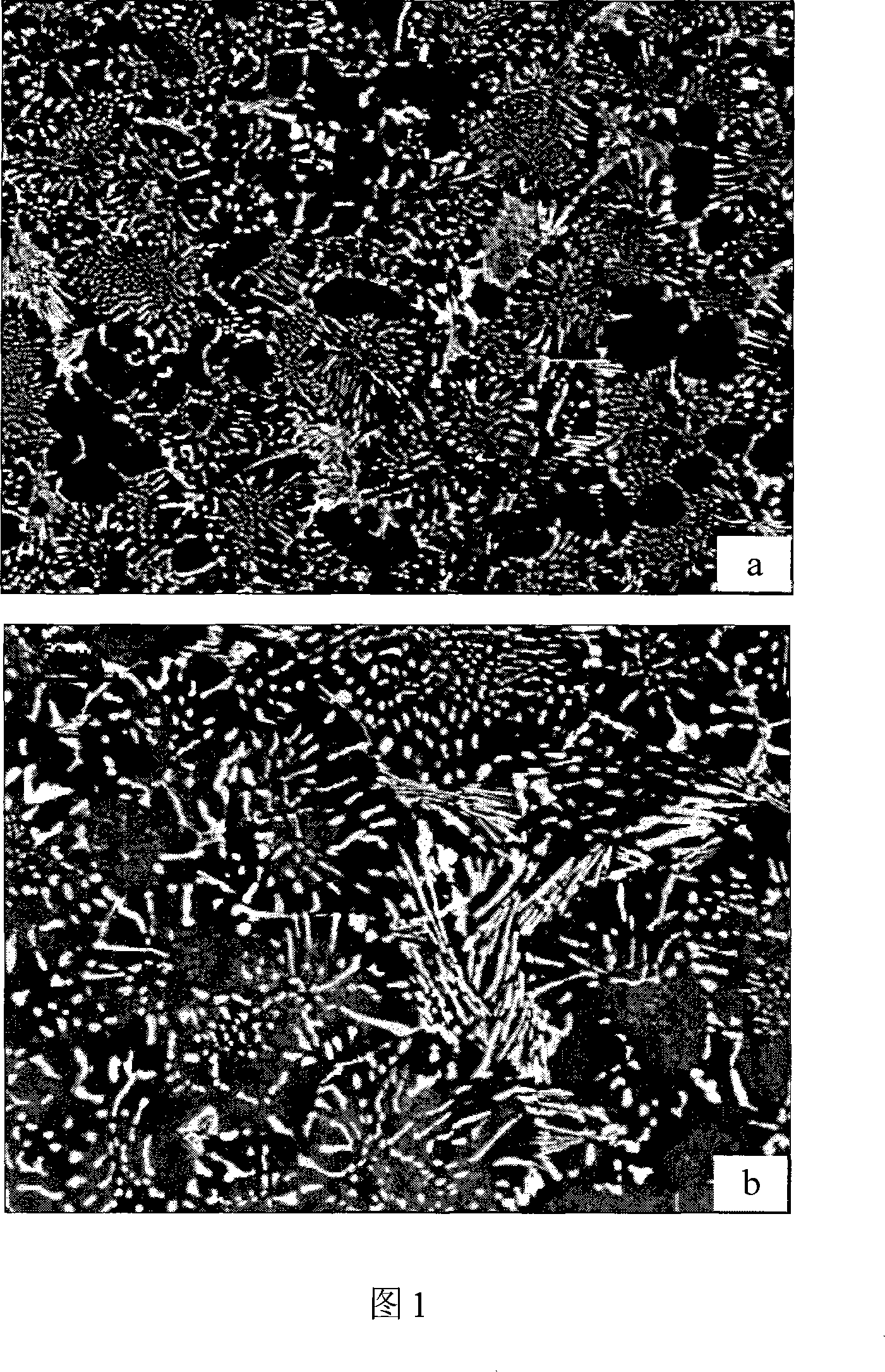

[0023] Through experimental observation and performance measurement, the high-speed steel composition designed by the present invention has good performance, and can obtain dispersedly distributed point-shaped, rod-shaped, strawberry-shaped MC-type high-vanadium eutectic carbides and lamellar M 2 C-type high molybdenum eutectic carbide. The microstructure is shown in Figure 1. The as-cast hardness can reach more than HSD90, and the heat treatment hardness is greater than HSD80, which has high hardness and high wear resistance. The hardness at 600...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com